In-situ carbon-coated copper-nickel alloy nanoparticle photocatalyst and preparation method and application thereof

A nanoparticle, copper-nickel alloy technology, applied in the field of materials science, can solve the problems of poor performance of photocatalytic carbon dioxide reduction, few surface active sites, and easy recombination of photogenerated carriers, so as to promote development, improve catalytic process, wide Effect of light absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

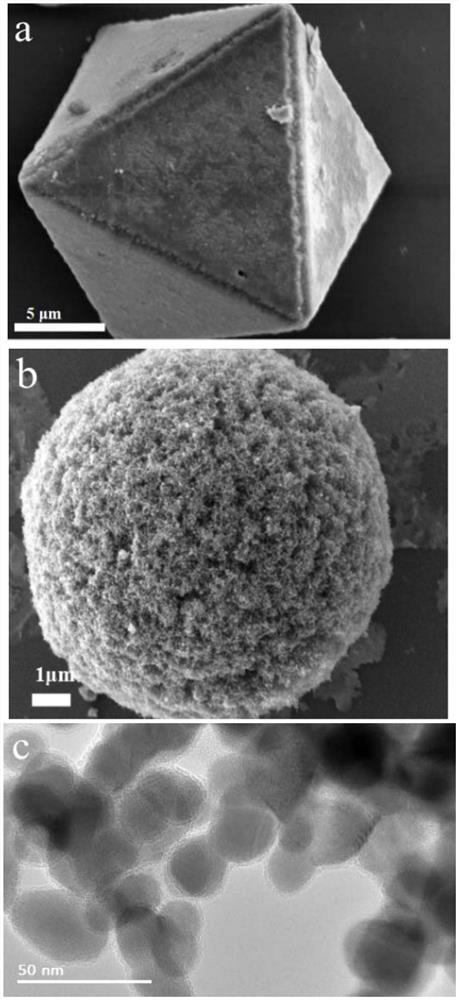

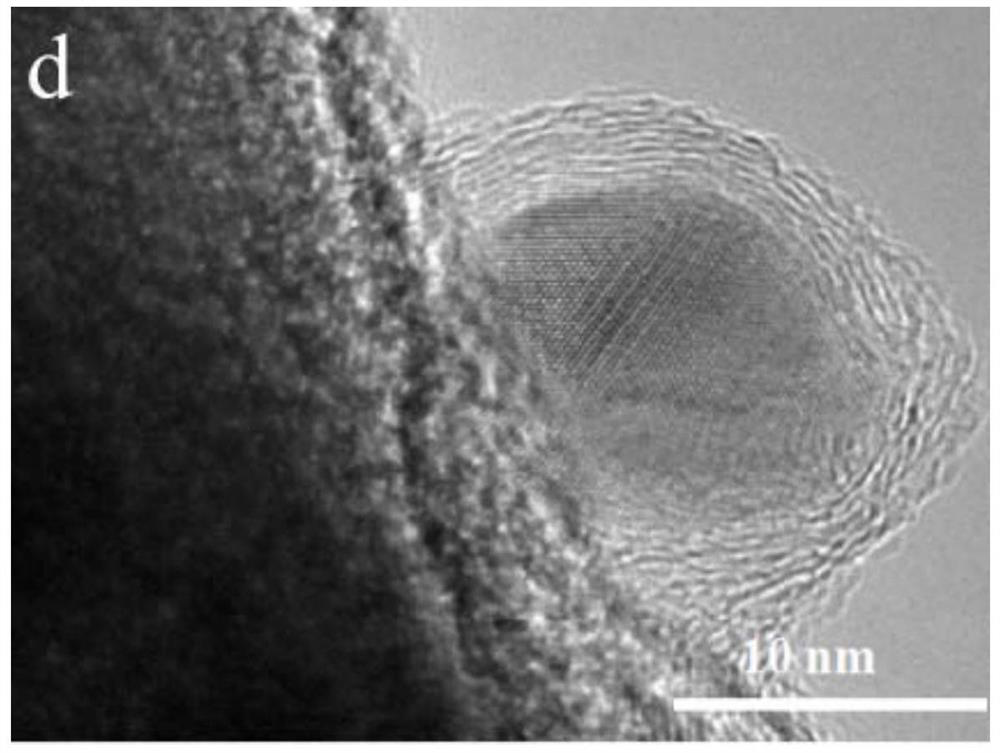

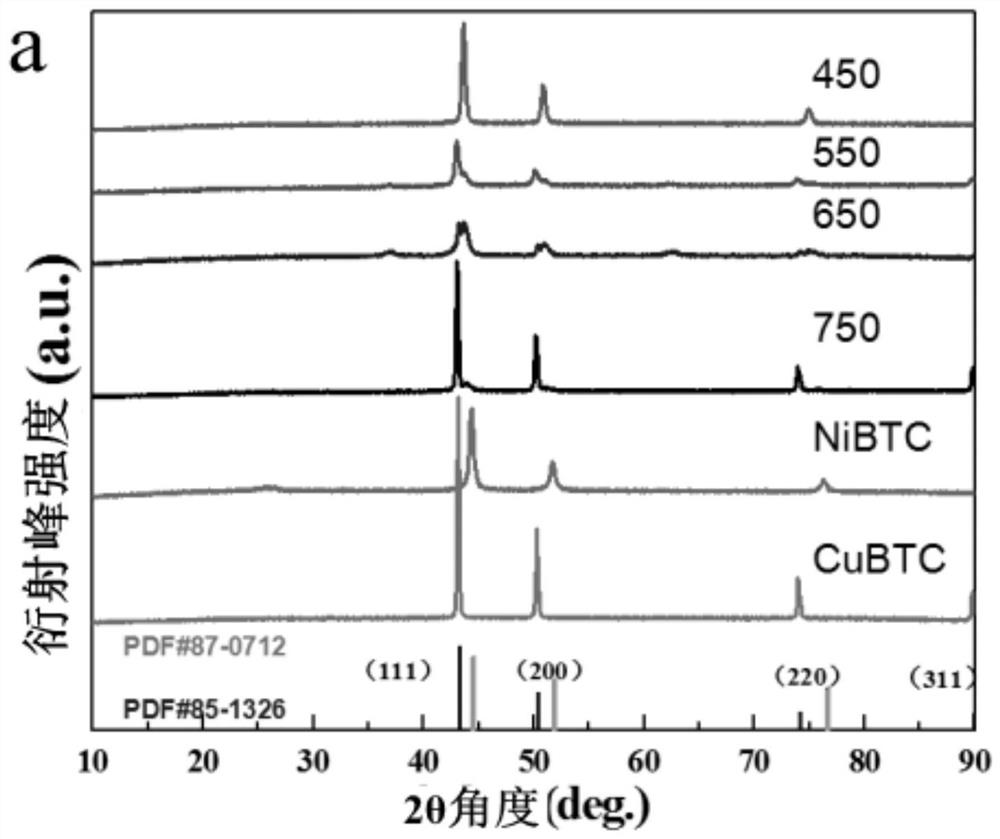

[0042] This embodiment provides an in-situ carbon-coated copper-nickel alloy nanoparticle photocatalyst, which mainly contains three main elements: Cu, C, and Ni. The preparation steps are as follows:

[0043] (1) Preparation of CuNiBTC

[0044] 0.42g of trimesic acid was dissolved in 40mL of absolute ethanol, and then 0.875g of Cu(NO 3 ) 2 2H 2 O and 0.975gNi(NO 3 ) 2 ·6H 2 O was dissolved in 15mL deionized water, and the former two were mixed evenly by stirring, and then the mixed solution was poured into a 100mL polytetrafluoroethylene reactor with a stainless steel shell, and put into an oven at 160 °C for 10 h. The precipitate is centrifuged at 8000r / min for 10min, and the obtained precipitate is washed with double distilled water and ethanol at a controlled speed of 8000r / min for 10min, and the above centrifugal washing is repeated for 7-8 times. The resulting filter cake is controlled at a temperature of Dry at 80°C, and the obtained product is CuNiBTC, which is t...

Embodiment 2

[0066] An in-situ carbon-coated copper-nickel alloy nanoparticle photocatalyst mainly contains three main elements of Cu, C and Ni, and is prepared by a method comprising the following steps:

[0067] (1) Preparation of CuNiBTC

[0068] 0.42g of trimesic acid was dissolved in 40mL of absolute ethanol, and then 0.875g of Cu(NO 3 ) 2 2H 2 O and 0.975gNi(NO 3 ) 2 ·6H 2 O was dissolved in 15mL deionized water, and the former two were mixed evenly by stirring, and then the mixed solution was poured into a 100mL polytetrafluoroethylene reactor with a stainless steel shell, and put into an oven at 160 °C for 10 h. Centrifuge the precipitate at 8000r / min for 10min, and then use double distilled water and ethanol to control the speed of 8000r / min to centrifuge and wash the precipitate for 10min, repeat the above centrifugal washing for 7-8 times, and control the temperature of the obtained filter cake Dry at 80°C, and the obtained product is CuNiBTC, which is taken out and stored...

Embodiment 3

[0074] An in-situ carbon-coated copper-nickel alloy nanoparticle photocatalyst mainly contains three main elements of Cu, C and Ni, and is prepared by a method comprising the following steps:

[0075] (1) Preparation of CuNiBTC

[0076] 0.42g of trimesic acid was dissolved in 40mL of absolute ethanol, and then 0.875g of Cu(NO 3 ) 2 2H 2 O and 0.975gNi(NO 3 ) 2 ·6H 2 O was dissolved in 15mL of deionized water, and the former two were mixed evenly by stirring, and then the mixed solution was poured into a 100ml polytetrafluoroethylene reactor with a stainless steel shell, and placed in a 160°C oven for 10h. Centrifuge the precipitate at 8000r / min for 10min, and then use double distilled water and ethanol to control the speed of 8000r / min to centrifuge and wash the precipitate for 10min, repeat the above centrifugal washing for 7-8 times, and control the temperature of the obtained filter cake Dry at 80°C, and the obtained product is CuNiBTC, which is taken out and stored i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com