Conductive paste, preparation method and application thereof, and battery

A conductive paste, paste technology, applied in conductive materials dispersed in non-conductive inorganic materials, battery electrodes, cable/conductor manufacturing, etc., can solve problems such as low conductivity, achieve high conductivity efficiency, easy dispersion, The effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] During the preparation of the conductive paste, the number of layers of the modified graphene and the diameter, purity and specific surface area of the carbon nanotubes will affect the conductivity of the obtained conductive paste.

[0033]For example: when the number of layers of the above-mentioned modified graphene is too thick, in the preparation process of the conductive paste, the modified graphene is prone to sedimentation, which affects the electrical conductivity of the conductive paste; when the number of layers of the above-mentioned modified graphene When it is too thin, the modified graphene is easy to float on the surface of the conductive paste during the preparation of the conductive paste and then agglomerates. Based on this, the number of layers of the above-mentioned modified graphene is 10-50 layers, so that the conductive paste obtained by combining the modified graphene, carbon nanotubes and conductive carbon black has high conductivity and high s...

Embodiment 1

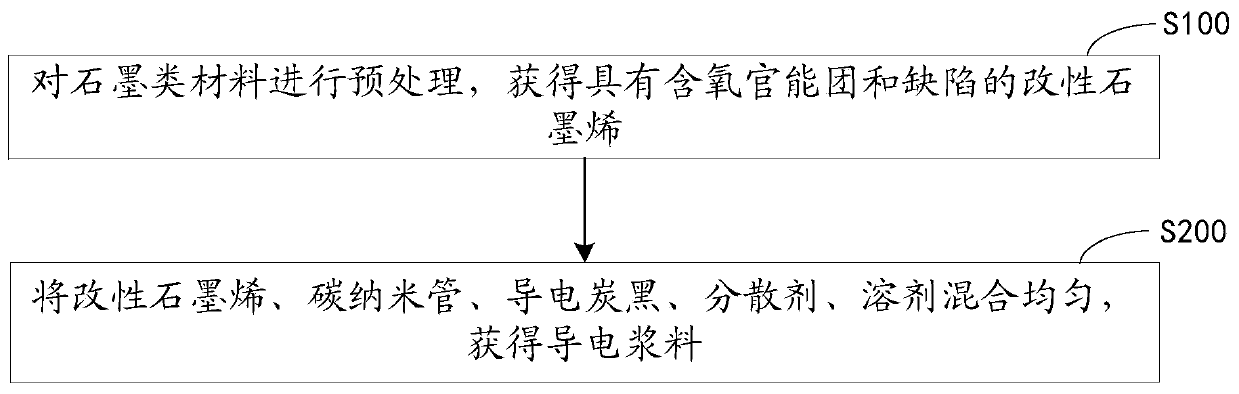

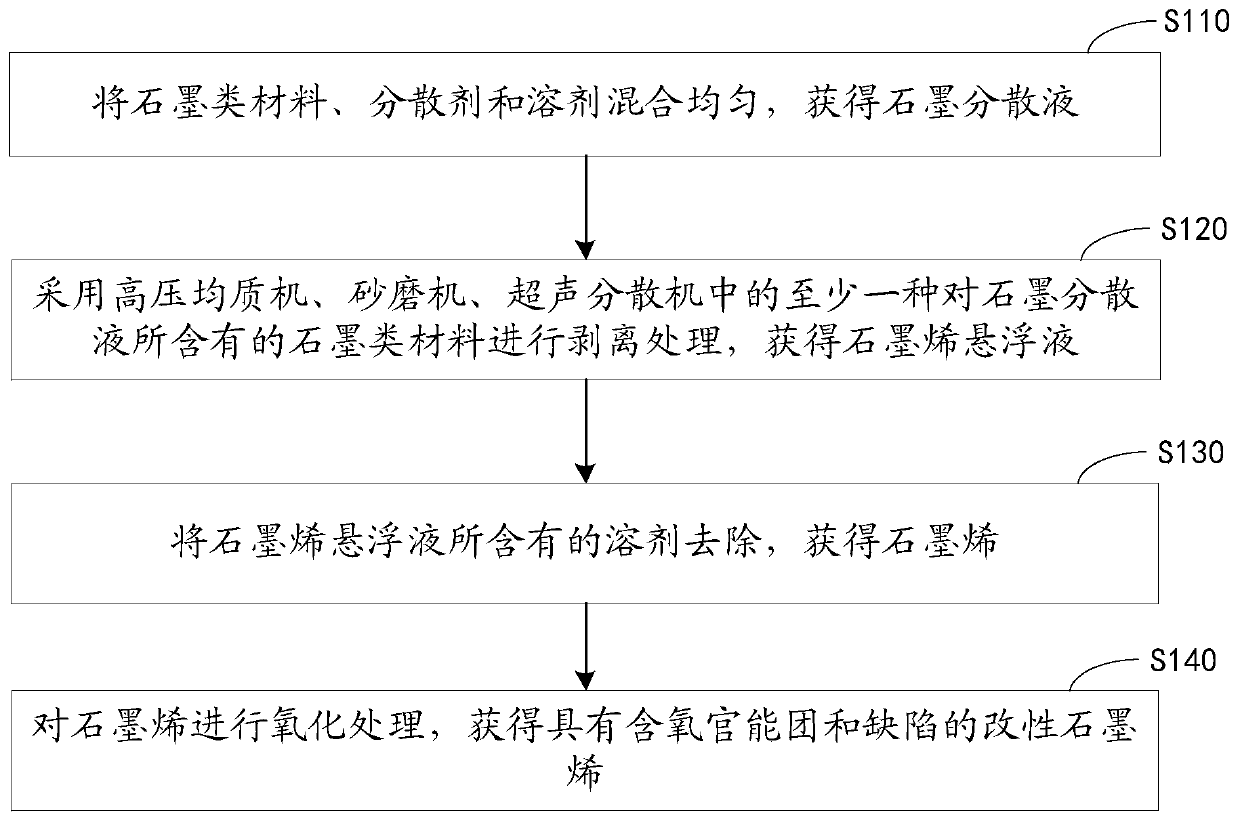

[0087] The embodiment of the present invention provides a preparation method of conductive paste, the preparation method of the conductive paste comprises:

[0088] Step 1: Put polyvinylpyrrolidone and N-methylpyrrolidone in a dispersion tank, and disperse for 30 minutes at a speed of 600 r / min to obtain a mixed solution.

[0089] The second step: the expanded graphite and the mixed solution are placed in a high-pressure homogenizer, and homogenized at 200Mpa for 2 hours to obtain a graphene suspension.

[0090] The third step: filter the graphene suspension to obtain graphene.

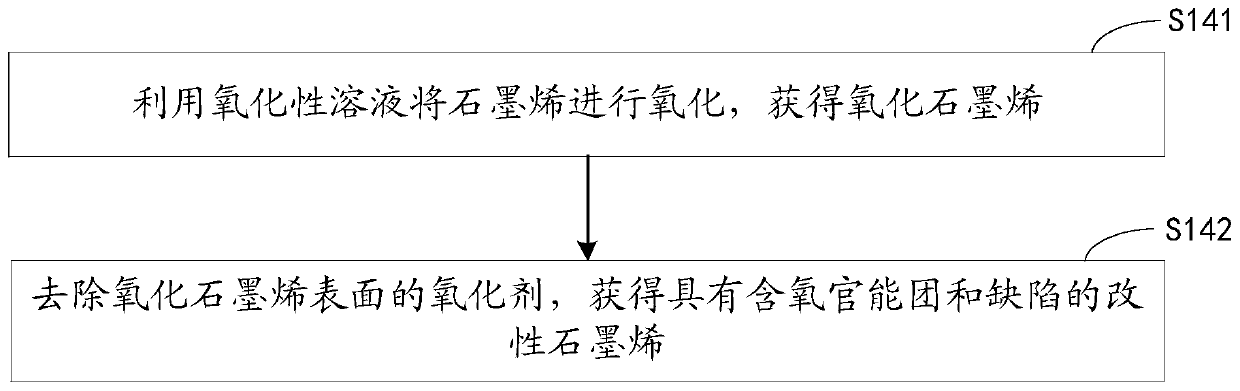

[0091] Step 4: Soak graphene in concentrated sulfuric acid:concentrated nitric acid oxidizing solution with a molar ratio of 1:1 for 30 minutes, and filter to obtain graphene oxide.

[0092] Step 5: washing the graphene oxide with deionized water to remove the oxidizing solution on the surface of the graphene oxide, and then drying at 80° C. to obtain modified graphene, the number of layers of the mo...

Embodiment 2

[0101] The embodiment of the present invention provides a preparation method of conductive paste, the preparation method of the conductive paste comprises:

[0102] Step 1: Put polyethylene glycol and deionized water in a dispersion tank, and disperse for 20 minutes at a speed of 500 r / min to obtain a mixed solution.

[0103] The second step: the expandable graphite and the mixed solution are placed in a high-pressure homogenizer, and homogenized at 300Mpa for 2.5 hours to obtain a graphene suspension.

[0104] The third step: filter the graphene suspension to obtain graphene.

[0105] Step 4: Soak the graphene in concentrated sulfuric acid for 10 minutes, and filter to obtain graphene oxide.

[0106] Step 5: washing the graphene oxide with deionized water to remove the concentrated sulfuric acid on the surface of the graphene oxide, and then freeze-drying to obtain the modified graphene, the number of layers of the modified graphene is 15 layers.

[0107] Step 6: Stir and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com