Tube-tube sheet fillet weld incomplete penetration defect height measurement system and method

A technology of height measurement and measurement system, which is applied in the direction of material analysis using radiation, etc., can solve the problems of quantitative measurement of incomplete penetration height and no proposal, and achieve the effects of improving evaluation accuracy, convenient processing, and true measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

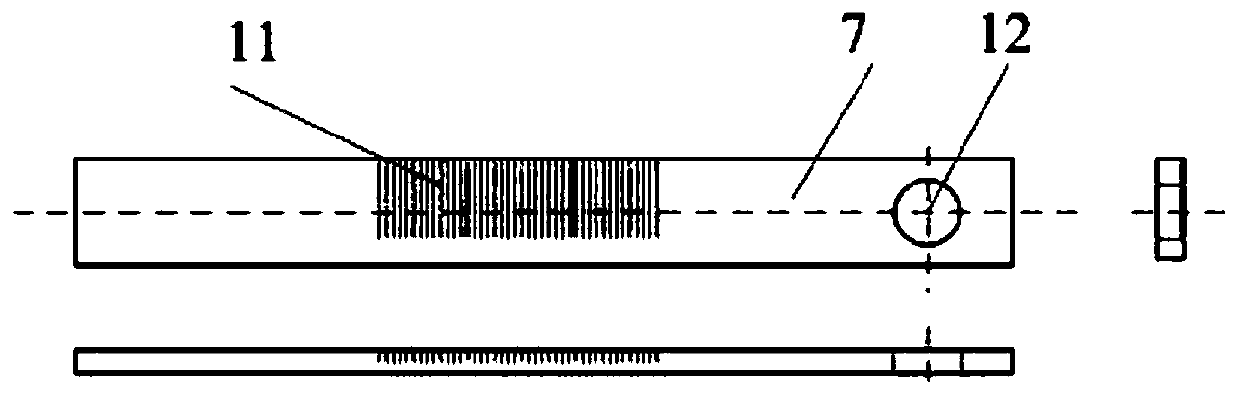

[0033] see figure 1 and figure 2 , this embodiment is illustrated by taking the strength-welded pipe-tube plate fillet weld of a chemical heat exchanger in our unit as an example in accordance with the ASME standard ray detection application, and the detection process and detection steps are carried out in the following order:

[0034] 1. Make the scale 7 according to the following conditions:

[0035] (1) The scale is made of stainless steel, which has a certain rigidity and is not easy to deform;

[0036] (2) The scale is evenly set on the scale, and the scale division accuracy of the scale is at least 0.5mm;

[0037] (3) The thickness of the scale is not more than 1mm, the depth of the scale is not more than 0.2mm, and the width is not more than 0.15mm;

[0038] (4) The scale is opened and installed with a round hole 12, and the round hole should be concentric with the compensation block and the rod anode of the X-ray machine;

[0039] (5) The "0" position of the scale...

Embodiment 2

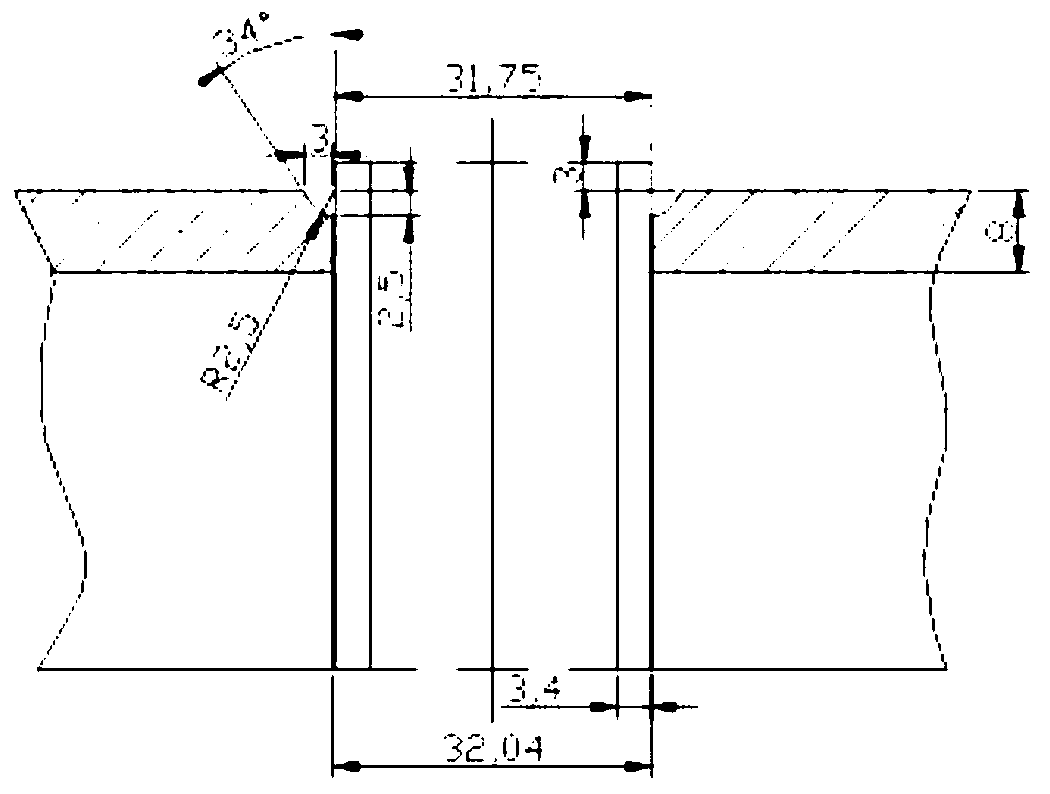

[0058] This example is for image 3 The strength welded pipe-tubesheet fillet weld structure of the chemical heat exchanger shown is measured. The specification of the pipe is Φ31.75×3.4mm (R=12.47mm), and the surface of the tubesheet is welded with 8mm thick surfacing welding. layer, the surfacing layer material is ALLOY 625, and the welding method is electroslag surfacing; the fillet weld groove is an arc groove with a radius of 2.5, and the welding height requirement is 2.5mm. The welding method is automatic argon tungsten arc welding. The pressure difference on both sides of the tube sheet is > 6Mpa, and the outer wall of the connecting tube is a chemical reaction medium, so the sealability and internal quality of the heat exchanger tube-tube sheet fillet welds are required to be high.

[0059] Inspection requirements: (negotiated by the manufacturer and the user) requires that the height limit of the non-penetration of the root be 0.5mm.

[0060] Except for the inner chu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com