Cooling water leakage monitoring method and device of material cooler

A monitoring device, cooler technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve problems such as leakage, and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

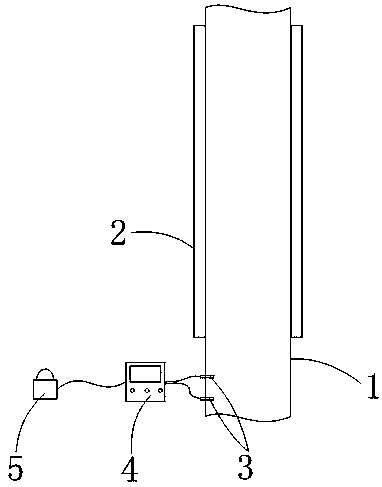

[0028] Such as figure 1 As shown, a material cooler cooling water leakage monitoring device includes a heat exchange housing 1 and a water cooling device 2. The water cooling device 2 covers the heat exchange housing 1, and the heat exchange housing 1 and the non-conductive The inner wall in contact with the solid material is provided with a resistance detection probe 3, and the resistance detection probe 3 is connected with a resistance detection instrument 4 through a cable.

[0029] Such as figure 1 As shown, the material cooler is a water-cooled vertical cooler, and the resistance detection probe 3 is set in the cooling section of the heat exchange shell 1 where the solid material is in a non-hot-melt state, which can ensure the accuracy of the detection data. At the same time, the resistance detection probes 3 can be set in one or more groups. When the resistance detection probes 3 are set in multiple groups, it is possible to conduct comprehensive real-time monitoring o...

Embodiment 2

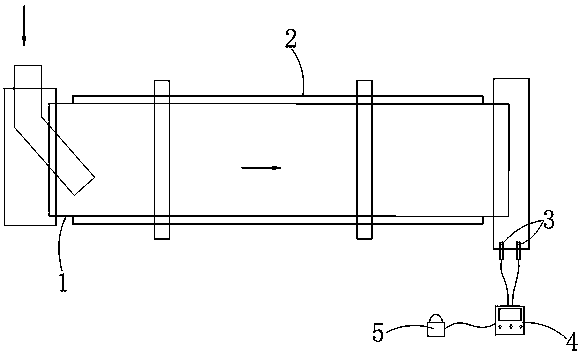

[0035] Such as figure 2 As shown, a cooling water leakage monitoring device for a material cooler includes a heat exchange housing 1 and a water cooling device 2. The water cooling device 2 covers the heat exchange housing 1, and the heat exchange housing 1 is connected to a non-conductive The inner wall in contact with the solid material is provided with a resistance detection probe 3, and the resistance detection probe 3 is connected with a resistance detection instrument 4 through a cable.

[0036] The resistance detection probe 3 is made of stainless steel. High temperature resistance, corrosion resistance, long service life.

[0037] The material cooler is a water-cooled horizontal drum cooler. The resistance detection probe 3 is arranged on the inner wall of the non-rotating heat exchange housing 1, and the power supply of the resistance detection instrument 4 is DC24V. The use of safe voltage can ensure the safety of operators.

[0038] Implementation process: Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com