An on-line monitoring device and method for pipeline leakage and corrosion based on fiber Bragg grating sensing

A fiber grating, pipeline leakage technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of unreusable oil and gas pipelines, high false alarm rate, and inability to complete replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

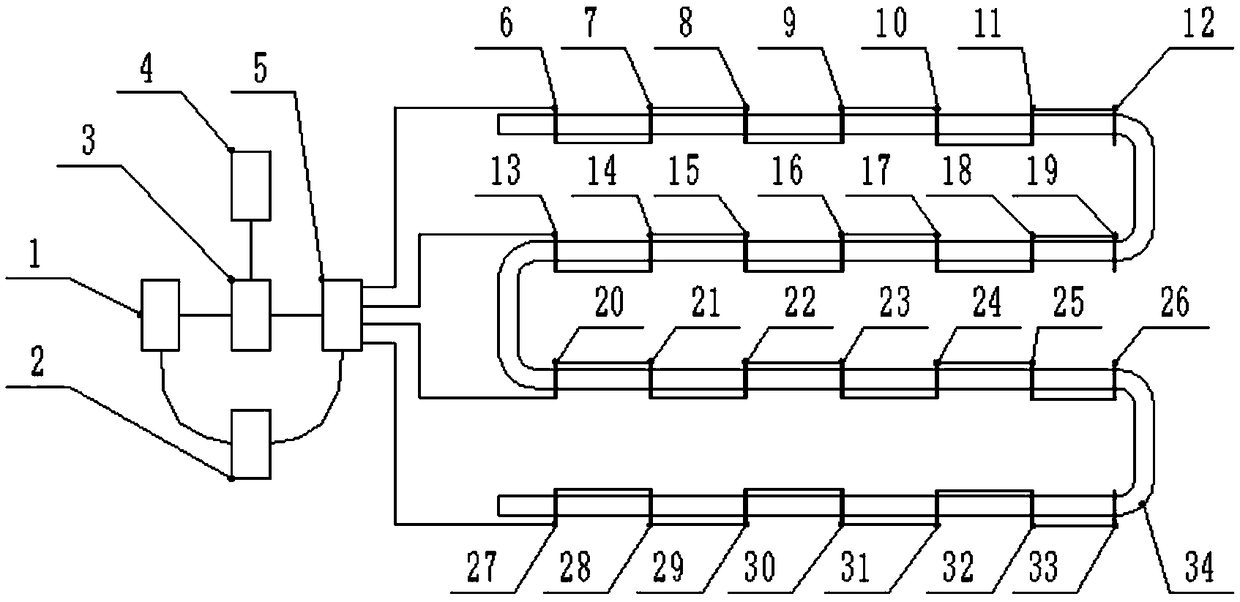

[0028] Such as figure 1 As shown, an on-line monitoring device for pipeline leakage and corrosion based on fiber grating sensing includes several fiber grating sensors packaged in composite materials, a spectroscopic system, a demodulation system 1 and a control system 2.

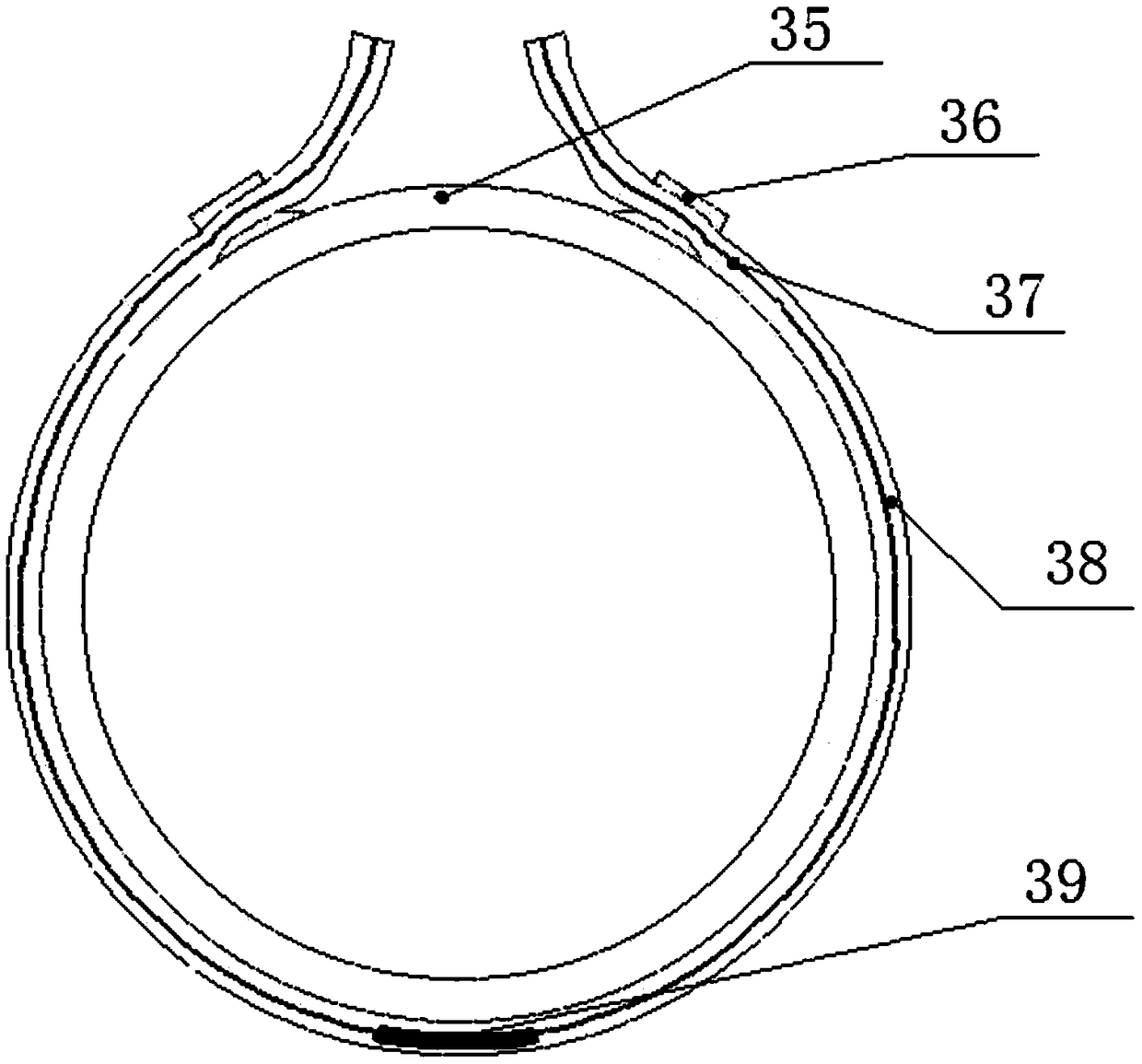

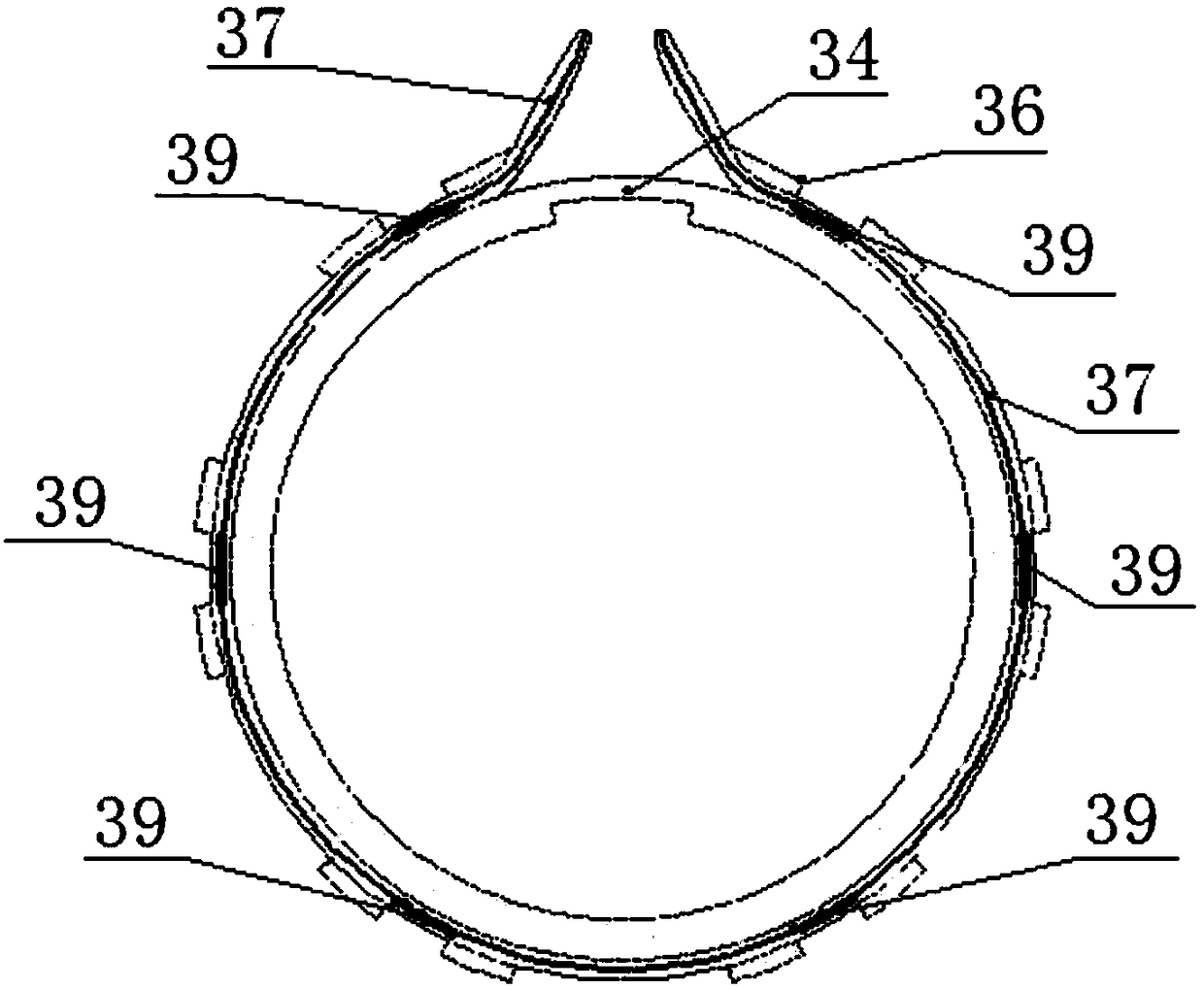

[0029] The fiber grating sensor is fixed on the outer wall of the long straight pipe 35 and the outer wall of the elbow place 34 with a certain preload (stretching amount is 2nm), and the fiber grating sensor (fiber grating sensors A1 to A6) fixed on the outer wall of the long straight pipe 35 , Fiber Bragg grating sensors R1 to B6, Fiber Bragg grating sensors C1 to C6, Fiber Bragg grating sensors D1 to D6) all have only one fiber Bragg grating 39 and are arranged equidistantly along the axial direction, and are fixed on the fiber Bragg grating sensor on the elbow place 34 outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com