A monitoring system and monitoring method for oil soil seepage in light oil depot area

A monitoring system and oil depot area technology, applied in the field of oil soil leakage monitoring system in light oil depot area, can solve the increased risk of leakage, unfavorable safety hazards, and the problem of leakage in light oil depot area can not be solved well and other issues to achieve the effect of improving accuracy and maintaining the safety of oil depots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better explain the purpose and application method of the present invention, the present invention will be further described below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

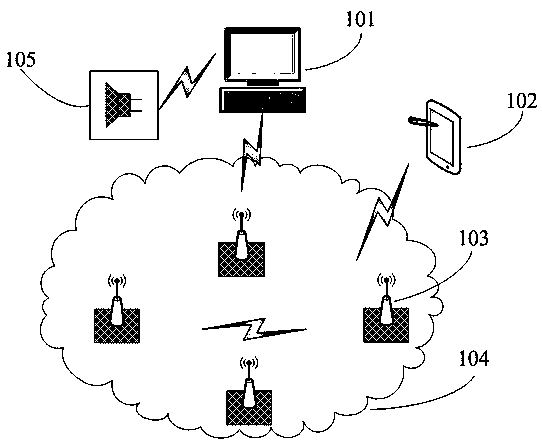

[0029] like figure 1 As shown, the present invention provides one embodiment. The system is generally composed of a central control computer 101 , a handheld terminal 102 , a soil leakage monitoring unit 103 and an alarm subsystem 105 . All the soil leakage monitoring units 103 form a wireless network 104 through the Zigbee protocol, and can be connected to the central control computer 101 through wired or wireless methods. When connecting through wireless methods, a wireless receiving device needs to be installed on the computer. The soil leakage monitoring unit 103 is buried in the soil below the oil pipeline in the reservoir area or in the soil around the oil tank, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com