Pipeline leakage on-line monitoring device and method based on f fiber temperature detection

A technology of pipeline leakage and optical fiber temperature measurement, which is applied in the direction of measuring devices, pipeline systems, thermometers, etc., can solve the problems of inaccurate positioning, high false alarm rate, and great influence on monitoring results, so as to improve response time and reduce false alarms rate, wide coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

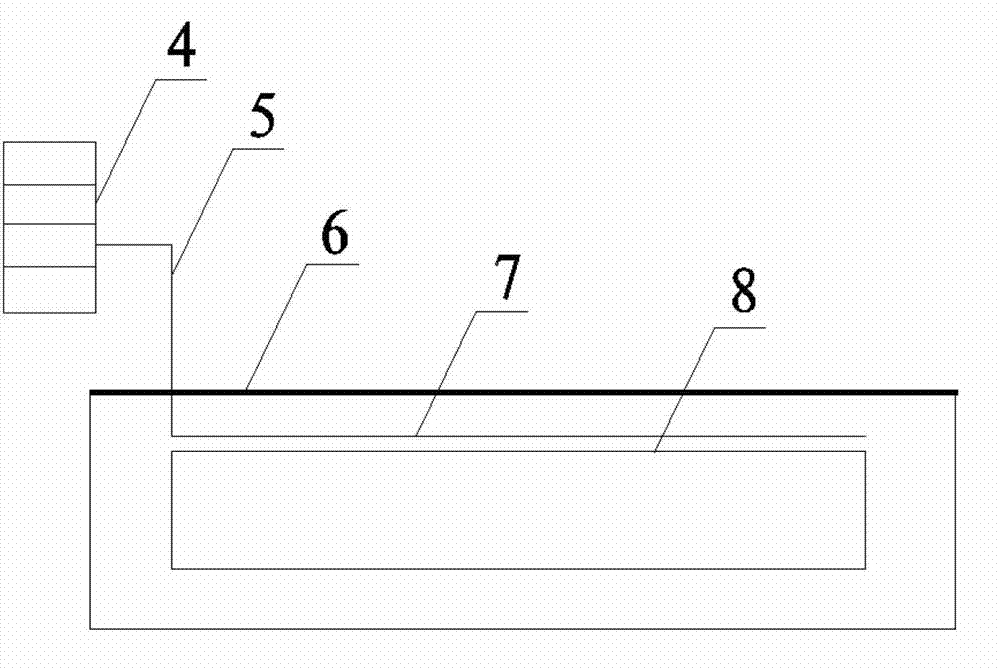

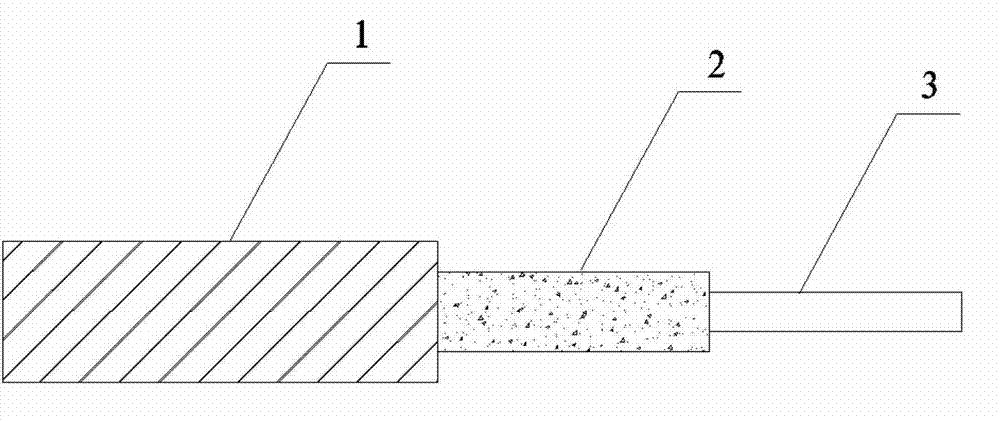

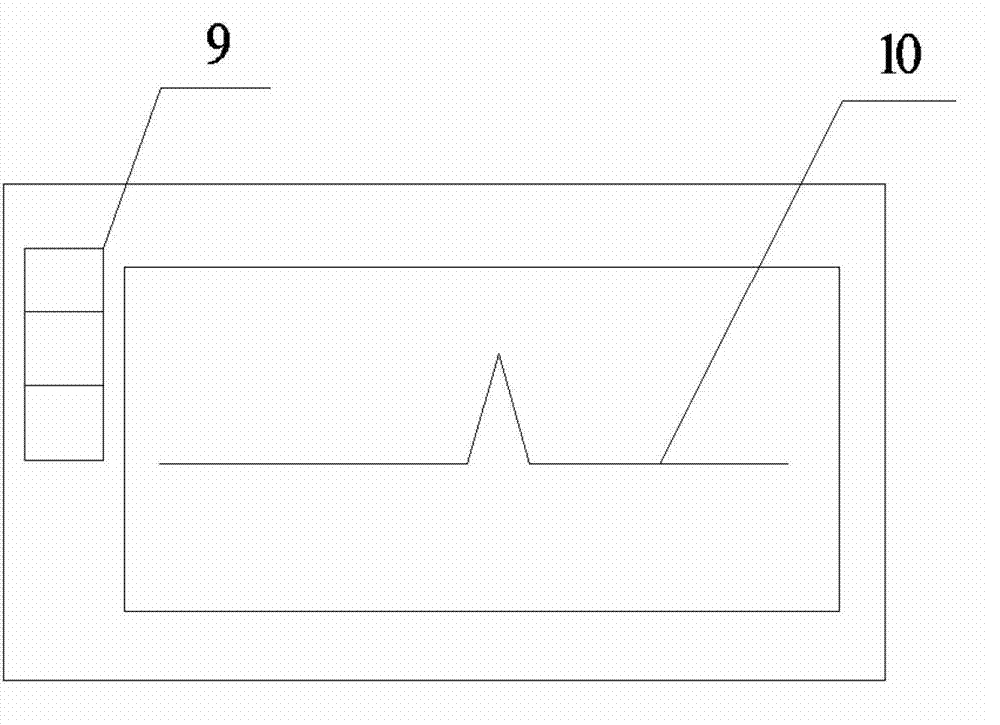

[0027] The on-line monitoring device for pipeline leakage based on optical fiber temperature measurement includes a monitoring host 4, a communication optical cable 5, an armored temperature sensing optical cable 7 and monitoring software; the monitoring host 4 includes a laser source, an optical unit, an optical fiber socket, a signal receiver, a wave Demultiplexer, amplifier, coupler, and processor are placed in the main control room; the armored temperature-sensing optical cable 7 includes double-layer twisted wire armor 1, protective sheath 2, temperature-sensing optical fiber 3, and communication optical cable 5 It is connected with the monitoring host 4 to form an overall hardware monitoring system.

[0028] On-line pipeline leakage monitoring device based on optical fiber temperature measurement, several parts of the hardware monitoring system involved and their functional descriptions:

[0029] 1. Double-layer twisted wire armored temperature-sensing optical cable

[...

Embodiment 2

[0038] An online monitoring method for pipeline leakage based on optical fiber temperature measurement, the specific steps of implementation are as follows:

[0039] 1) laying optical cable

[0040] When the pipeline is laid, the temperature-sensing optical cable is laid out synchronously, and the armored temperature-sensing optical cable 7 and the transmission pipeline 8 are bound together by stainless steel tape. The distance between the optical cable and the pipeline should be less than 30 cm, which can ensure the accuracy of temperature measurement. . During the laying process, if the site conditions do not allow the laying of the entire optical cable, it can also be laid in sections, and then the sections are connected by fusion fibers, and the joints are sealed and protected.

[0041] 2) Signal test

[0042] After the laying is completed, a signal test is performed on the armored temperature-sensing optical cable 7 to confirm that the entire optical cable can carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com