material supply device

A technology for supplying devices and inner containers, applied in dispensing devices, special dispensing devices, packaging, etc., to achieve the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

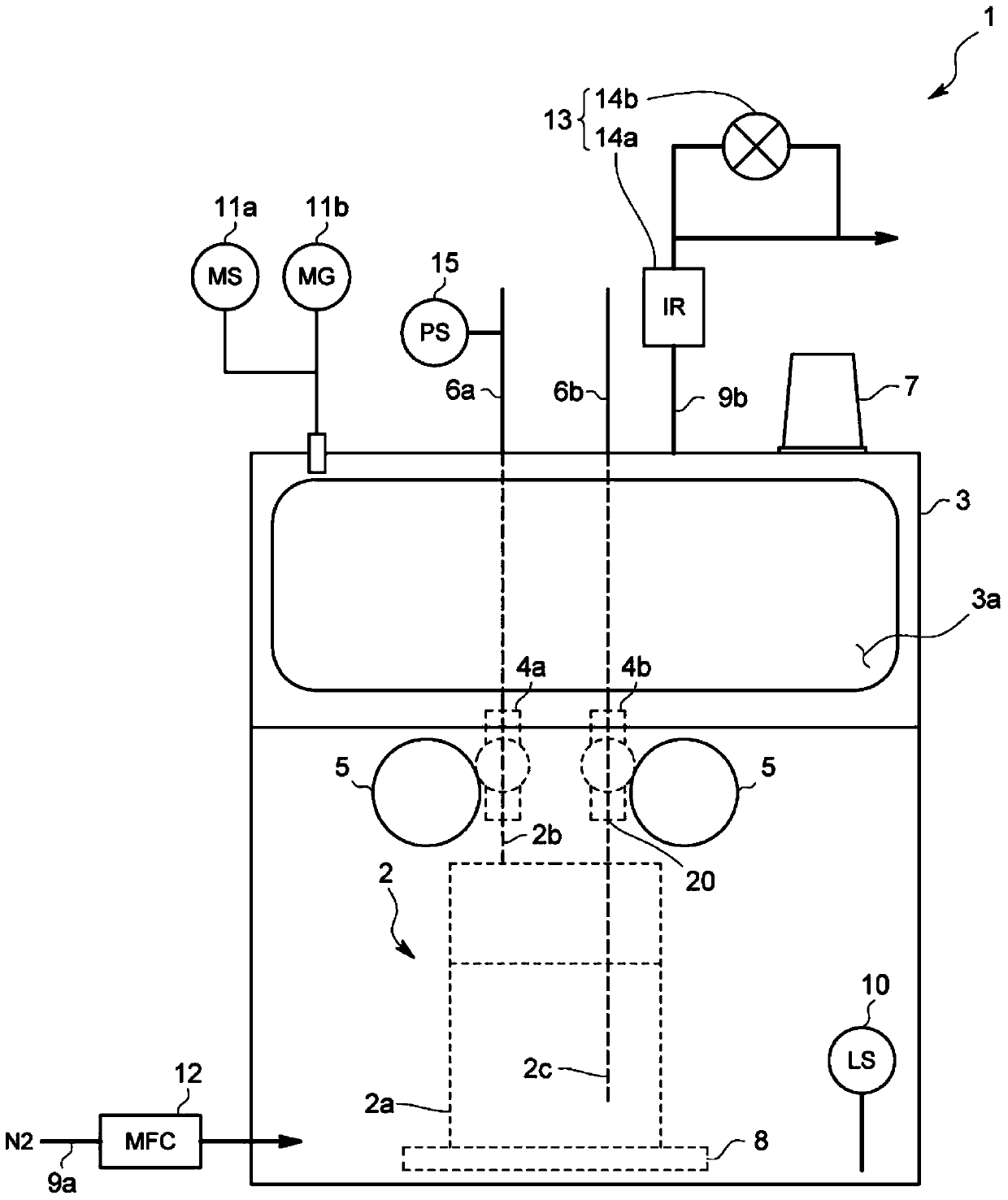

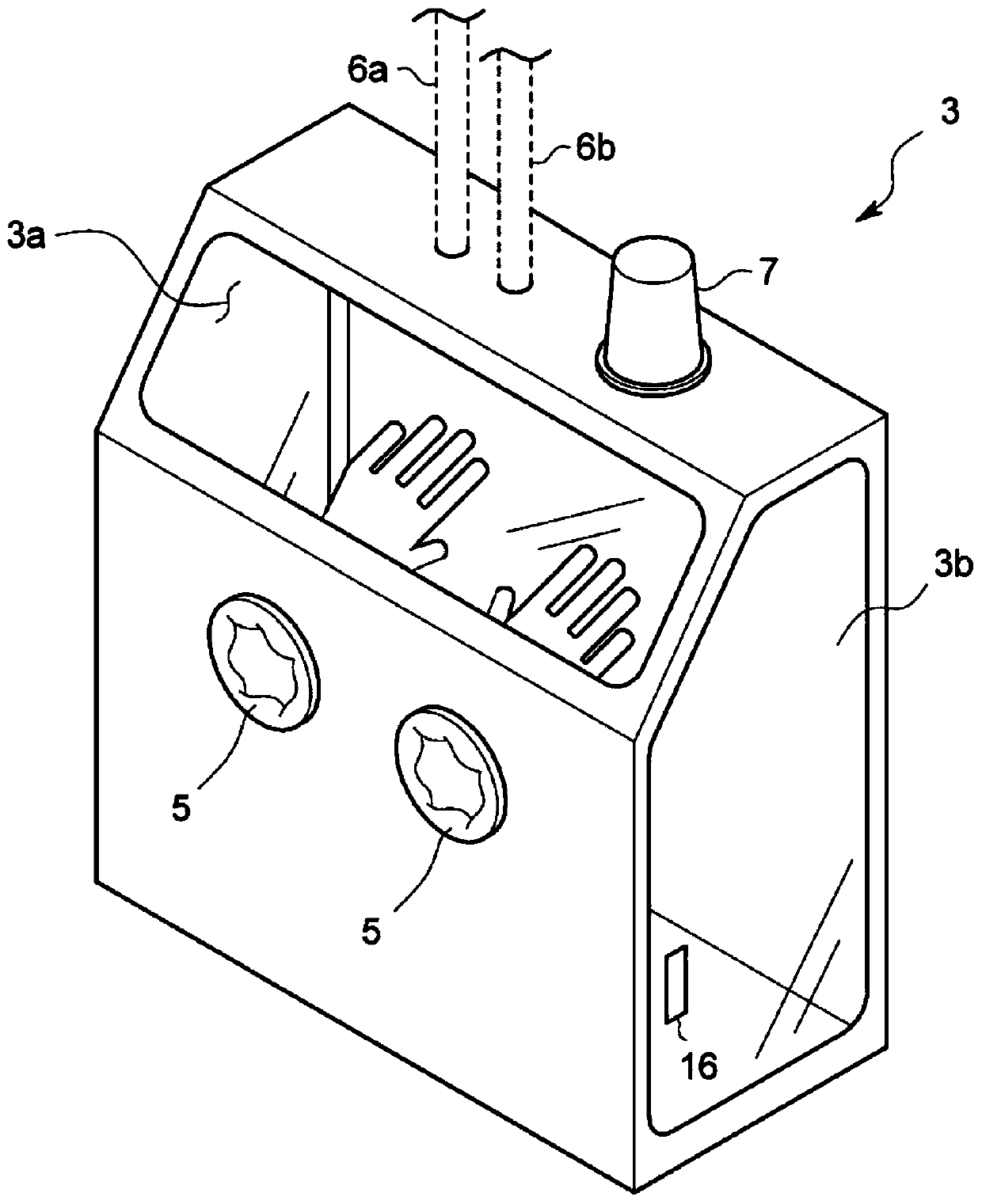

[0030] One embodiment of the material supply device of the present invention will be described below.

[0031] Such as figure 1 and figure 2 As shown, the material supply device 1 of this embodiment is a device that constitutes a part of a semiconductor manufacturing device. The material supply device 1 includes: an inner container 2 for containing a semiconductor material (for example, a liquid material with pyrophoric properties such as trimethylaluminum); The container 3 accommodates the inner container 2 so as to isolate the inner container 2 from the outside air; and the supply pipe 6b penetrates the outer container 3 and is connected to the inner container 2, and supplies the inner container 2 to a predetermined device such as a semiconductor manufacturing room. liquid material.

[0032] The inner container 2 includes: a hollow casing 2a for containing the liquid material; a first tubular body 2c provided so as to penetrate the upper wall of the casing 2a; and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com