Gas-phase filter material and filter unit

A technology of filter unit and filter material, applied in filtration separation, dispersed particle filtration, separation method, etc., can solve the problems of large specific surface area, great harm to human body, small particle size of PM2.5, etc., to achieve large specific surface area, excellent Mechanical properties, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The porous PLA micro-nano fiber membrane is prepared by the following steps:

[0041] 1) Ultrasonic dispersion of GO in N-methylpyrrolidone according to a solid-liquid ratio of 1:6, and then add L-lactic acid monomer, the weight ratio of GO to L-lactic acid monomer is 1:3, drain through nitrogen, The mixture is uniformly heated to 120°C within 45 minutes, and the polycondensation reaction occurs after stirring for 12 hours at a stirring speed of 500 rpm. After the reaction is completed, it is filtered and dried to obtain GO-g-PLLA nanoparticles;

[0042] 2) According to the solid-liquid ratio of 1:5, the GO-g-PLLA nanoparticles are ultrasonically dispersed in NH 2 In the OH·HCl solution (pH=7), drain with nitrogen, stir the reaction for 3 hours at a temperature of 65°C and a stirring speed of 500 rpm, filter and dry after the reaction, to obtain rGO-g-PLLA nanoparticles;

[0043] 3) Disperse rGO-g-PLLA nanoparticles in dichloromethane ultrasonically, then add PLA, stir well to...

Embodiment 2

[0046] The porous PLA micro-nano fiber membrane is prepared by the following steps:

[0047] 1) Ultrasonic dispersion of GO in N-methylpyrrolidone according to a solid-liquid ratio of 1:6, and then add L-lactic acid monomer, the weight ratio of GO to L-lactic acid monomer is 1:3, drain through nitrogen, The mixture is uniformly heated to 120°C within 45 minutes, and the polycondensation reaction occurs after stirring for 12 hours at a stirring speed of 500 rpm. After the reaction is completed, it is filtered and dried to obtain GO-g-PLLA nanoparticles;

[0048] 2) According to the solid-liquid ratio of 1:5, the GO-g-PLLA nanoparticles are ultrasonically dispersed in NH 2 In the OH·HCl solution (pH=7), drain with nitrogen, stir the reaction for 3 hours at a temperature of 65°C and a stirring speed of 500 rpm, filter and dry after the reaction, to obtain rGO-g-PLLA nanoparticles;

[0049] 3) Disperse rGO-g-PLLA nanoparticles in dichloromethane ultrasonically, then add PLA, polyvinylpyr...

Embodiment 3

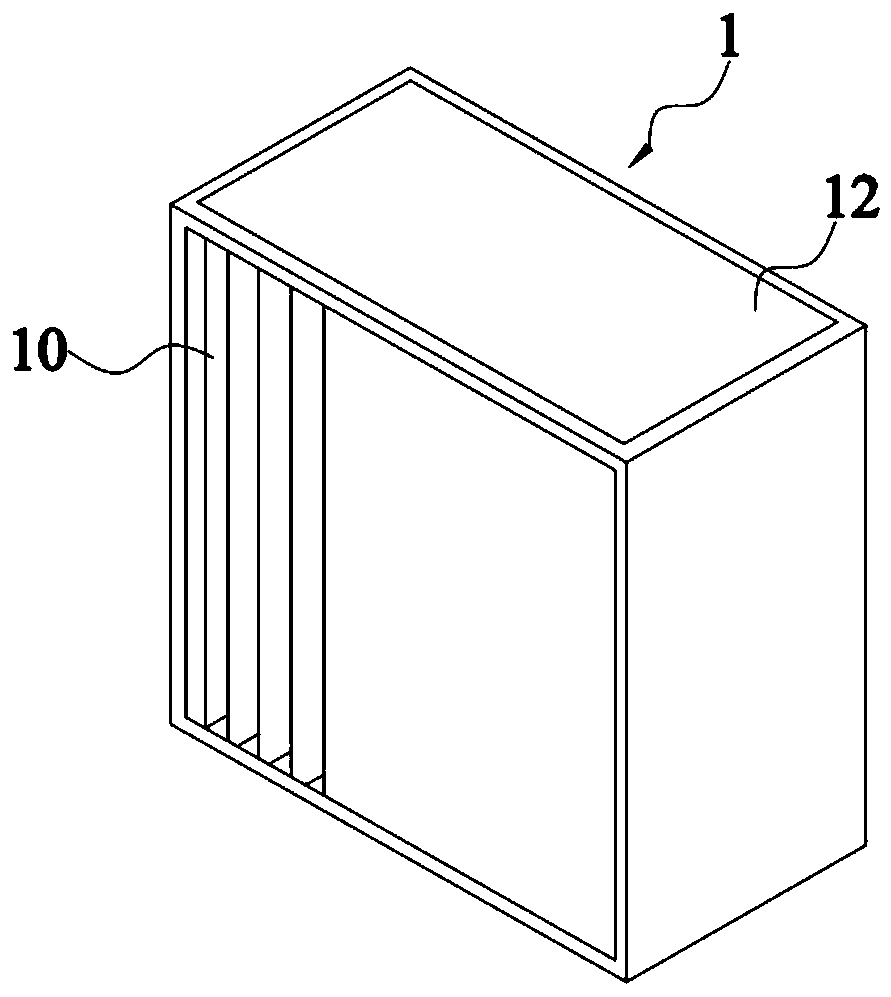

[0052] Such as Figure 2-4 As shown, the gas-phase filter material 10 has an air-permeable cover layer 101, a pre-collection layer 102, a main capture layer 103, and a gas-permeable support layer 104 sequentially stacked from the upstream side of the airflow; the air-permeable cover layer 101 is selected by the average fiber diameter The spunbonded non-woven fabric composed of 15μm polycaprolactone fibers allows dust in the airflow to pass through, and prevents the surface of the filter material from deforming when pressed from the outside; the pre-collection layer 102 uses an average fiber diameter of 2μm A non-woven fabric composed of polycaprolactone, using a hot-melt adhesive to heat-laminate the air-permeable cover layer 101 and the pre-capturing layer 102 at 110°C to form a laminate I, which is used to trap dust in the airflow The main trapping layer 103 includes the porous PLA micro-nano fiber membrane obtained in Example 1, which traps dust after passing through the pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com