Corn ear and kernel linkage drying production line

A corn cob and production line technology, applied in grain drying, dry solid materials, dry cargo handling, etc., can solve the problems of easy mildew, insect damage, rodent damage, affecting the quality and use of corn, waste gas, high temperature of flue gas, etc. Achieve the effects of improving harvesting efficiency and energy utilization, avoiding quality deterioration, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

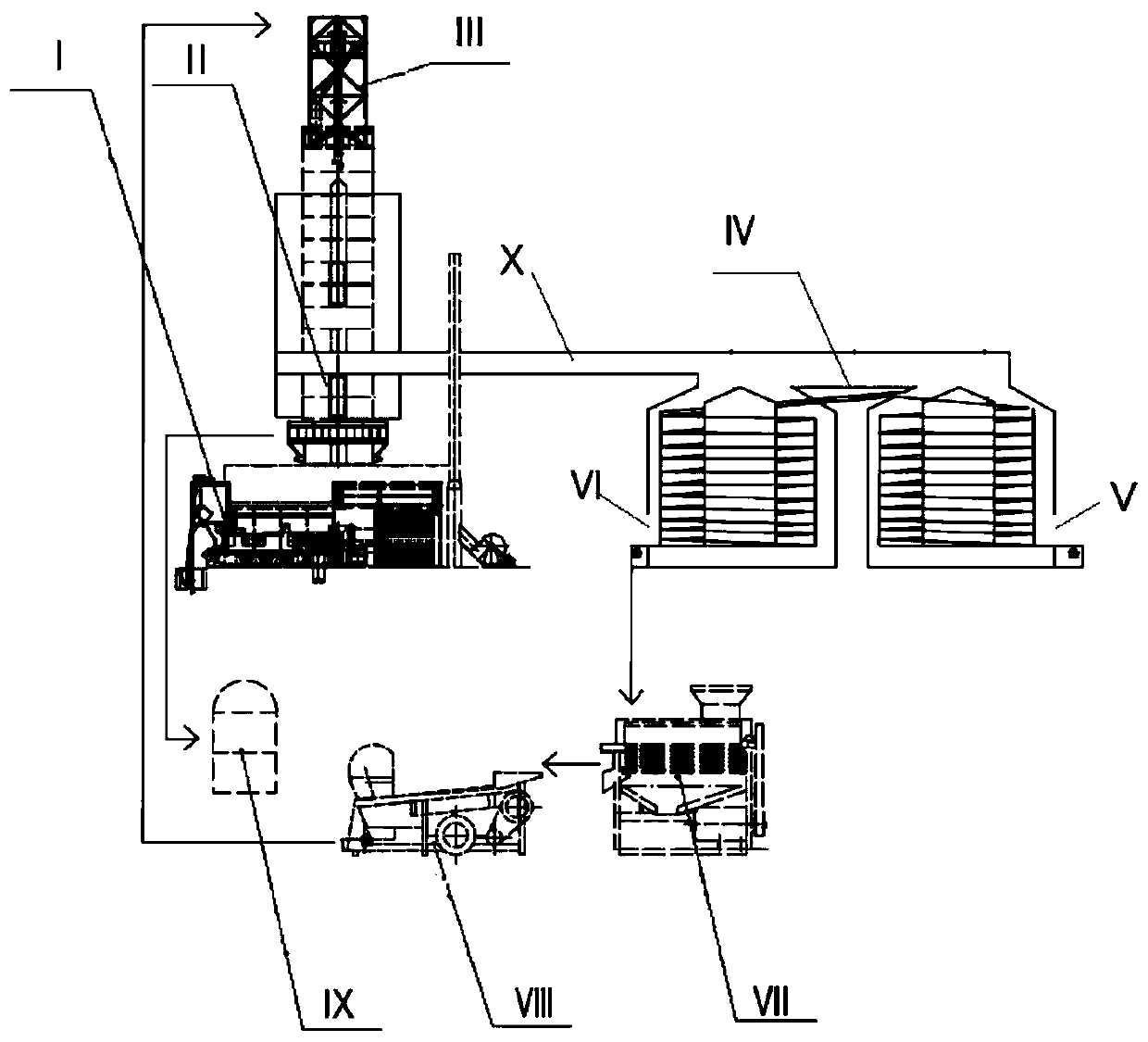

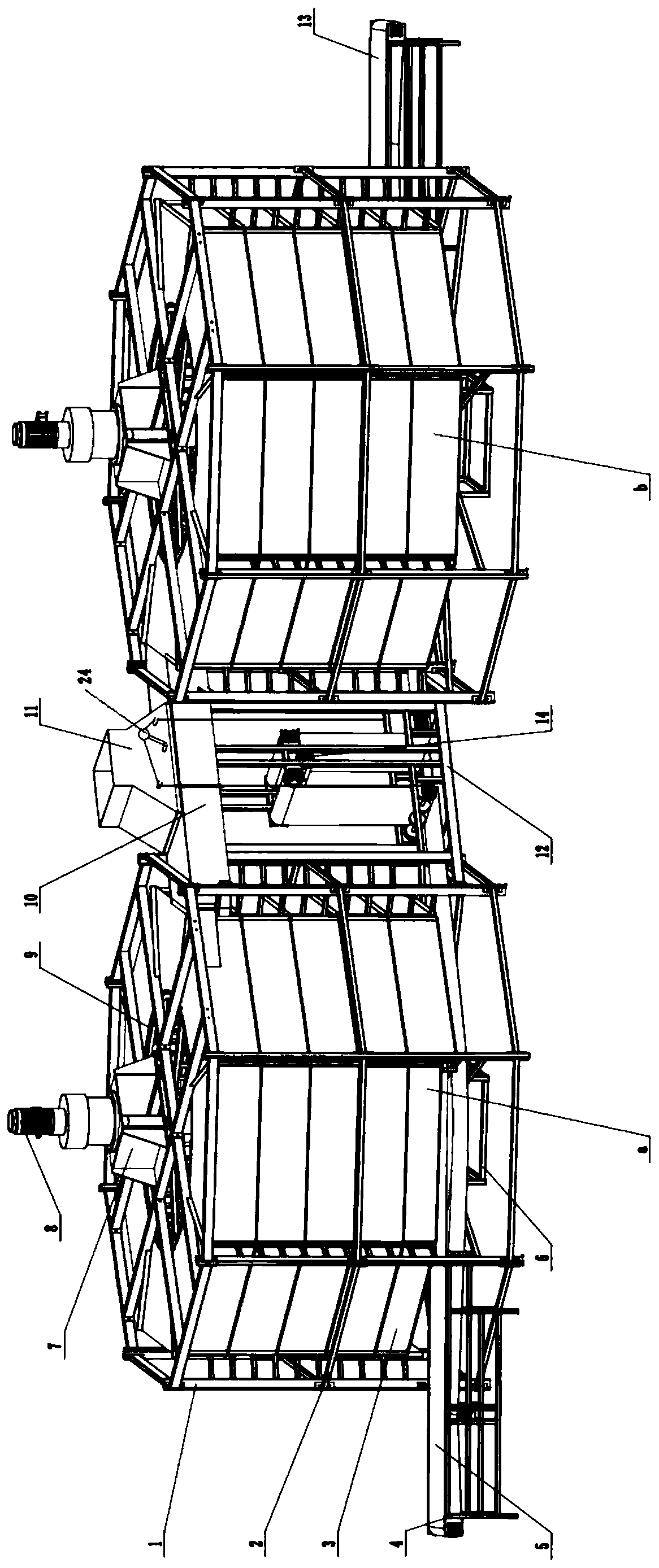

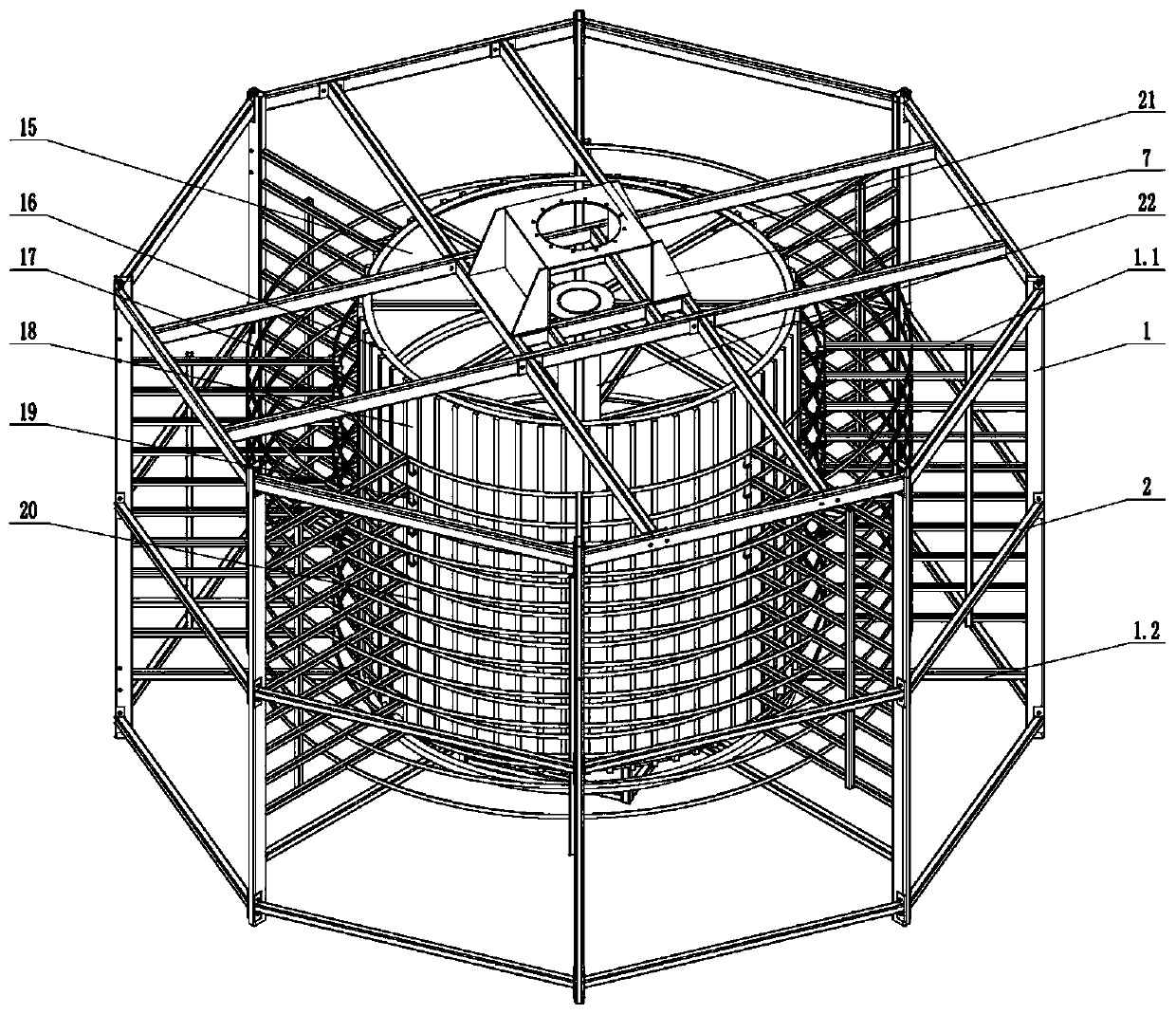

[0063] Attached below figure 1 - attached Figure 7 The drying production line disclosed in this embodiment is further described;

[0064] Refer to attached figure 1 As shown, the corn cob drying production line includes:

[0065] Ear dryer IV is used to dry corn ears, and its outlet is connected to corn thresher VII through a belt conveyor; its heat source is the waste heat of grain dryer II, and the exhaust air outlet of grain dryer II is connected through pipeline X To the air inlet of the ear dryer IV, use the waste heat of the grain dryer II to dry the corn ears. The power source is the high-pressure fan of the grain dryer II and the fan installed at the air inlet of the ear dryer IV. The grain dryer II The waste heat gas is transported to the fan at the air inlet of the ear dryer IV, and the fan provides hot air power to the ear dryer and assists natural wind drying; corn ears enter the ear dryer IV from the ear feed port V for drying, and after drying The corn ears ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com