Hydraulic oil cylinder based on decompression and force reduction

A hydraulic cylinder and pressure relief technology, which is applied in the field of hydraulic cylinders based on pressure relief and force reduction, to achieve the effects of improving stability, simple and convenient installation, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

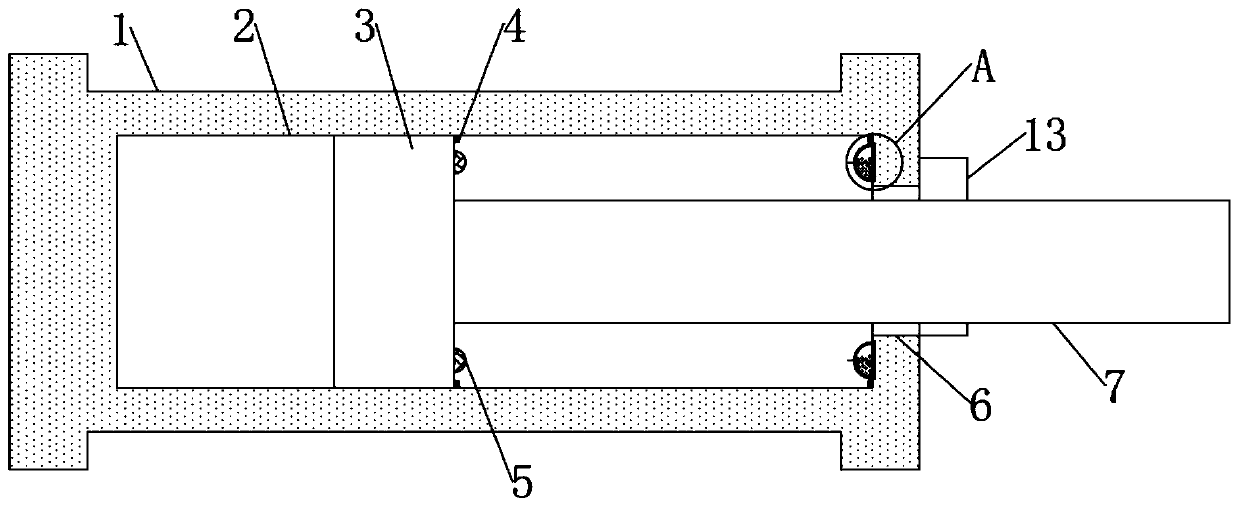

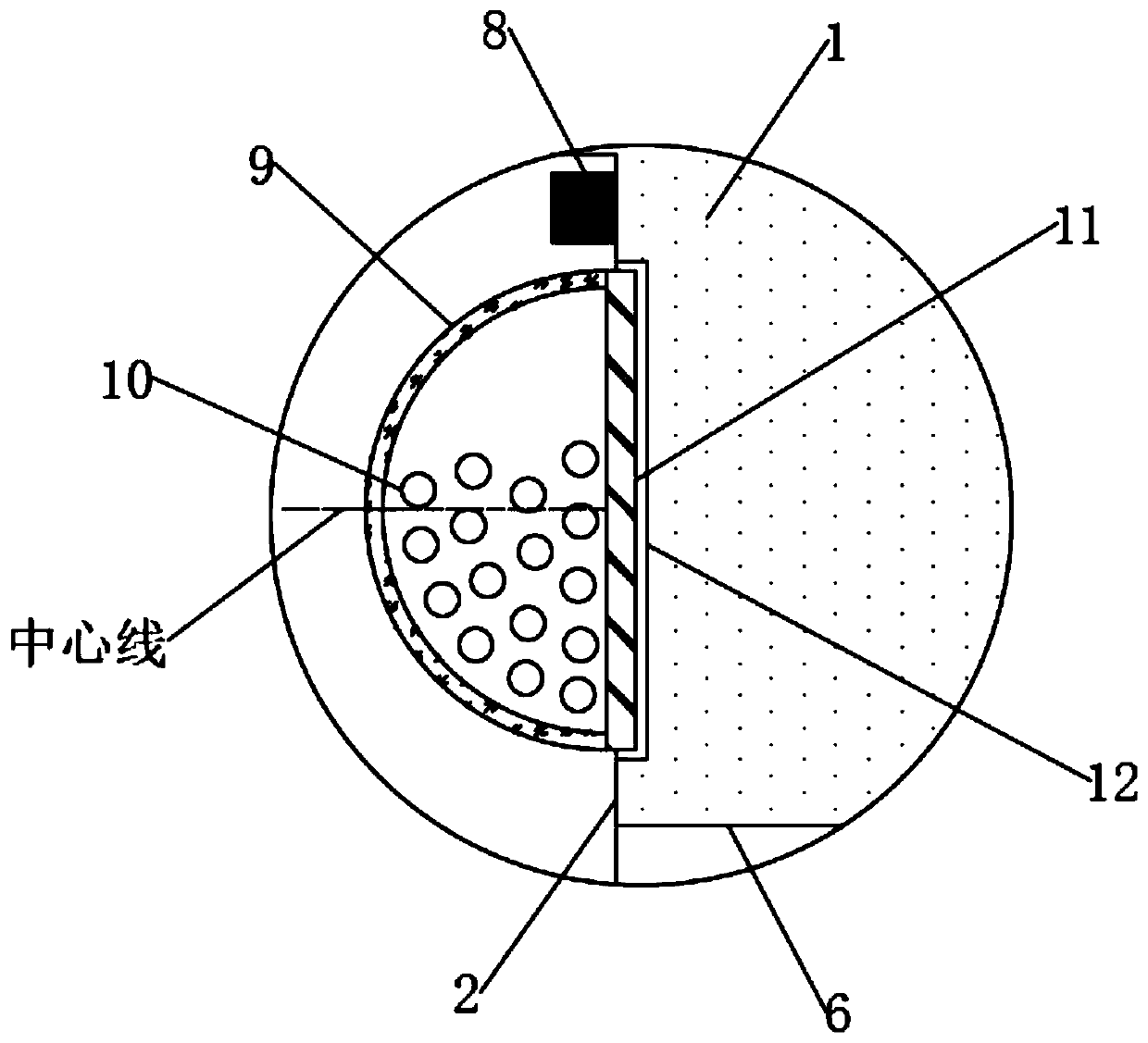

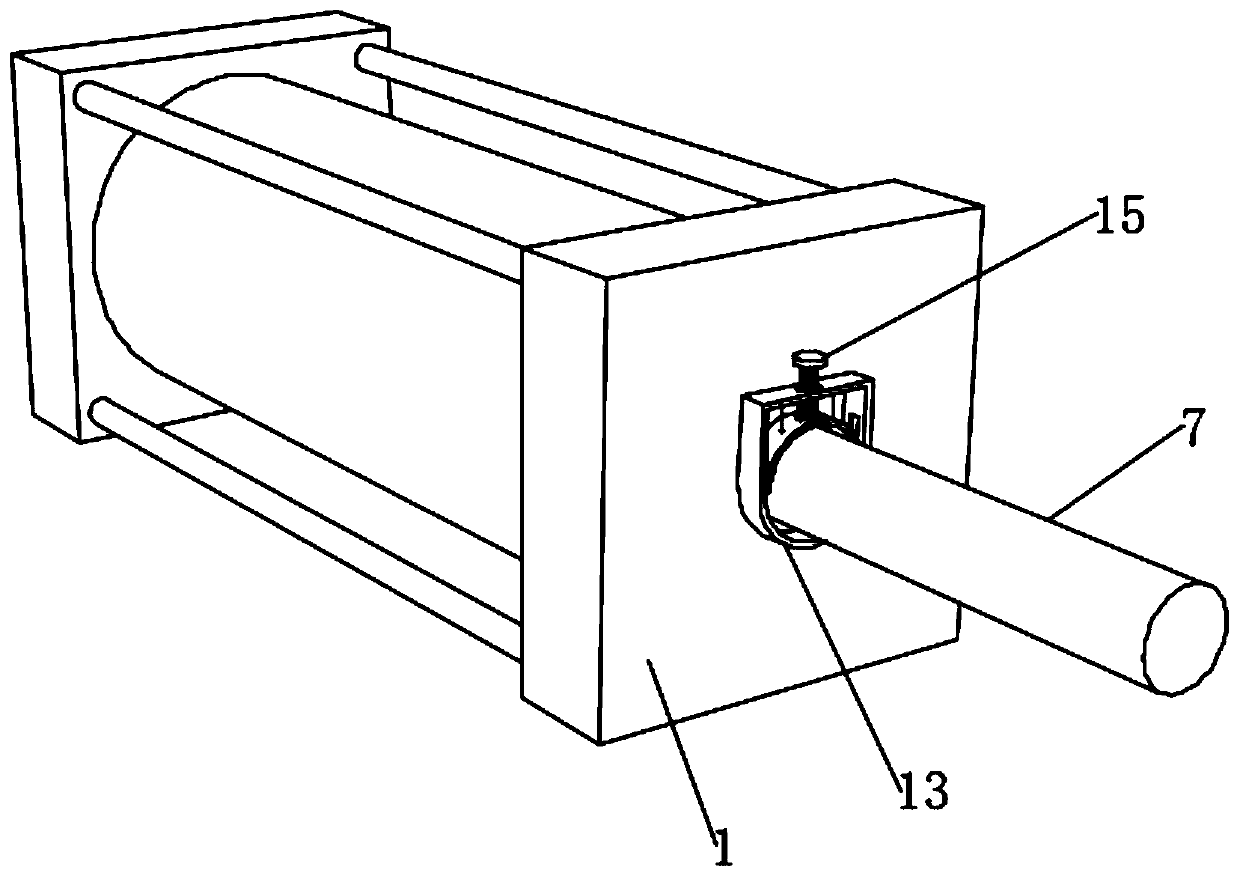

[0043] see figure 1 , a hydraulic cylinder based on pressure relief and force reduction, including a hydraulic cylinder body 1, an oil storage chamber 2 is excavated inside the hydraulic cylinder body 1, a telescopic port 6 is dug at the right end of the hydraulic cylinder body 1, and the telescopic port 6 is connected to the oil storage chamber 2 The piston 3 is slidingly connected to the oil storage chamber 2, the piston rod 7 is fixedly connected to the right end of the piston 3, the piston rod 7 is matched with the telescopic port 6, and the right end of the piston 3 is fixedly connected to two rubber raised hemispheres 5, two rubber The raised hemisphere 5 is symmetrical about the piston rod 7, the area of the rubber raised hemisphere 5 is smaller than the area of the rubber wrapped hemisphere 9, and the position of the centerline of the rubber raised hemisphere 5 and the position of the centerline of the rubber wrapped hemisphere 9 are located on the same horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com