A kind of bifunctional starch-based composite nanoparticle and its preparation method and application

A composite nanoparticle and functional technology, applied in the field of starch deep processing, can solve the problems of poor stability of double emulsion and limited industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] One aspect of the embodiments of the present invention provides a method for preparing bifunctional starch-based composite nanoparticles, which includes:

[0051] Perform hydrolysis treatment on starch to form starch hydrolyzate and obtain linear dextrin;

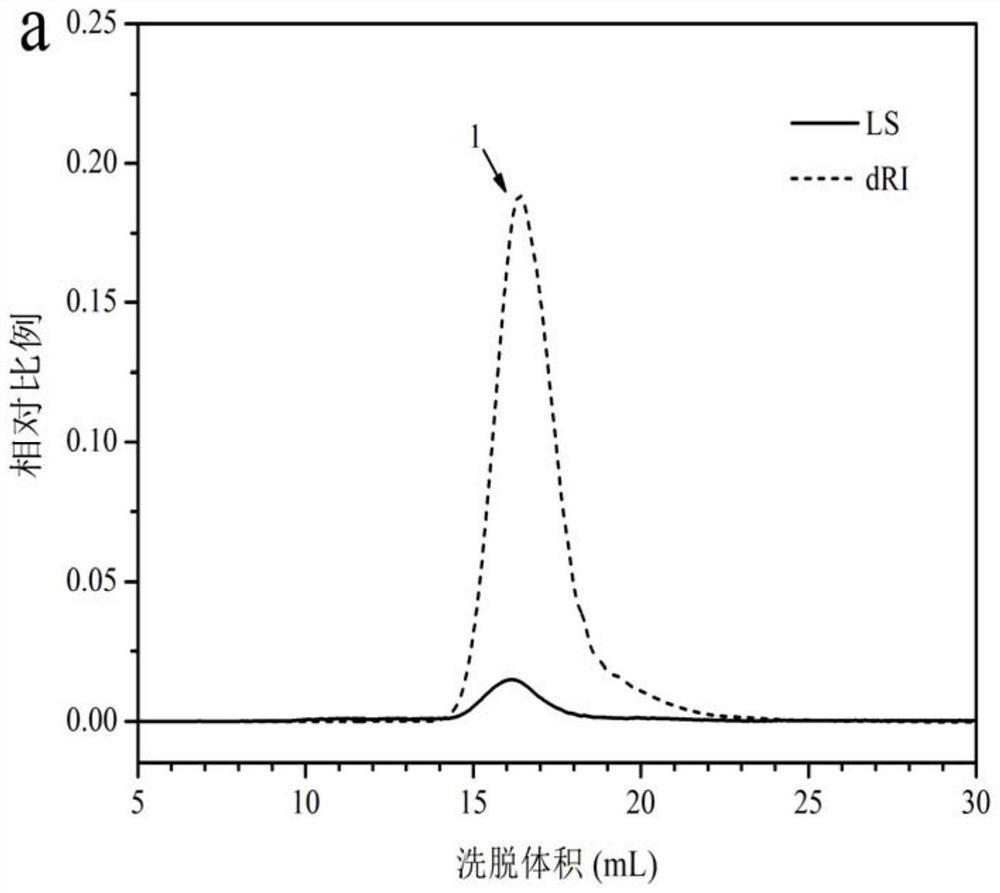

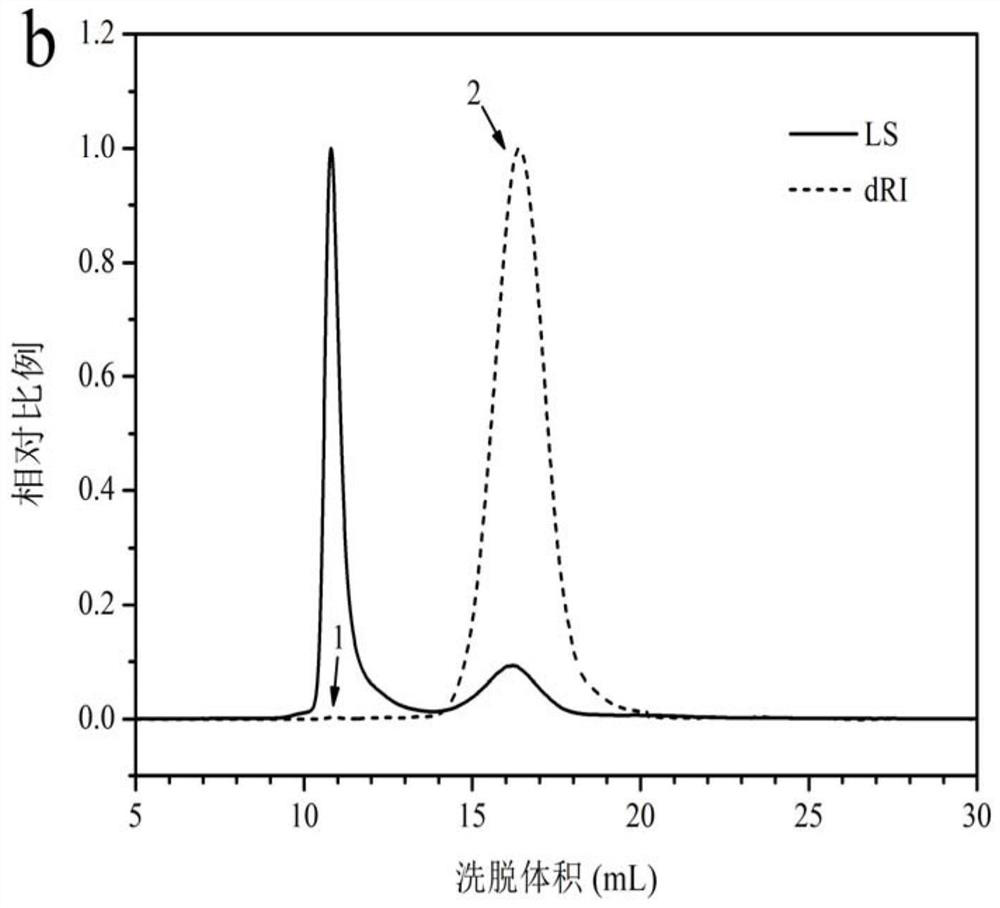

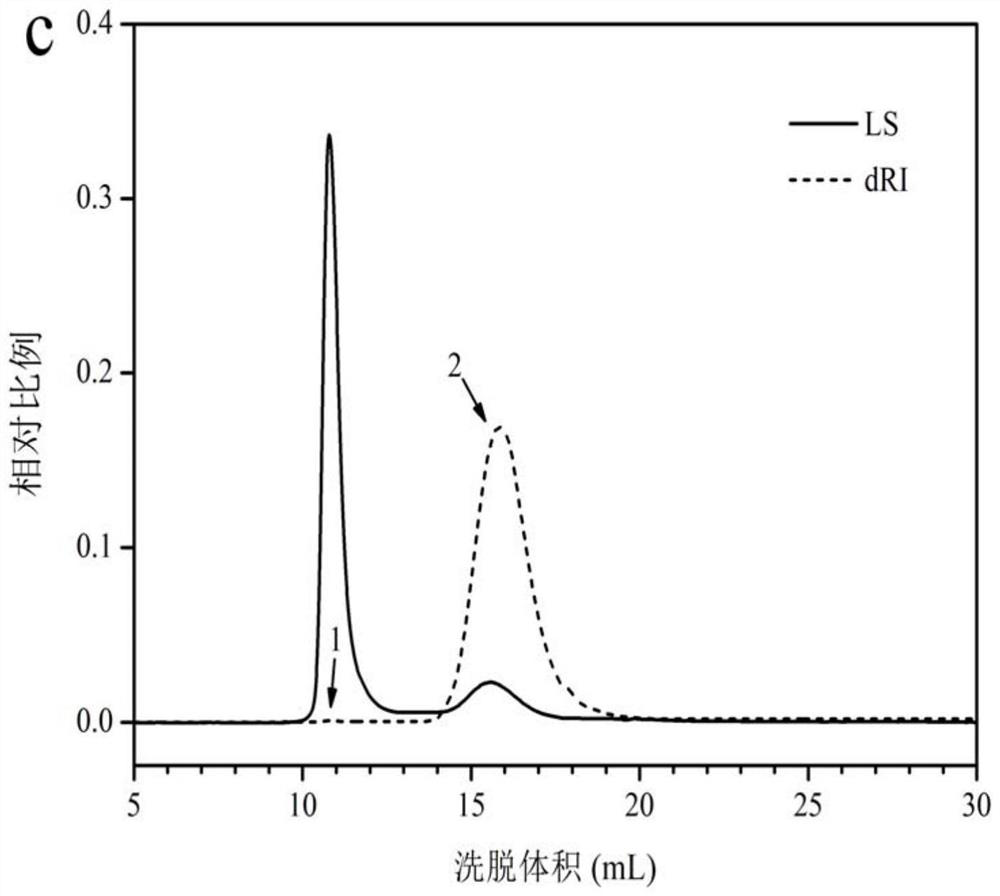

[0052] The linear dextrin is classified by an alcohol-alcohol gradient precipitation method to obtain a linear dextrin with uniform molecular weight distribution;

[0053] Oxidizing the linear dextrin by using a TEMPO / NaClO / NaBr oxidation system to obtain oxidized dextrin;

[0054] making the first mixed system comprising oxidized dextrin and curcumin undergo a complex reaction to form an oxidized dextrin-curcumin complex; and,

[0055] Make the oxidized dextrin-curcumin complex and chitosan hydrochloride form oxidized dextrin-curcumin / chitosan hydrochloride composite nanoparticles through electrostatic complexation to obtain the bifunctional starch-based composite nanoparticles.

[0056] In some embodiments, the ...

Embodiment 1

[0138] 1) Preparation of linear dextrin (LD)

[0139] 20g of ordinary cornstarch is configured into starch milk with a mass fraction of 5wt%, placed in a boiling water bath and stirred for 1h to completely gelatinize the starch, and further place the gelatinized starch in an acetate solution (0.02mol / L, with a pH of 6) Add 80U α-amylase, carry out hydrolysis treatment at 60°C for 1.5h, heat up to 100°C for enzyme inactivation treatment, add 1000U pullulanase for debranching treatment at 55°C for 3h, after the reaction, put the reaction solution in Inactivate the enzyme in a boiling water bath for 10 minutes. The reactant was centrifuged at 4500 g for 20 min, the precipitate was discarded, the supernatant was subjected to rotary evaporation, and vacuum freeze-dried to obtain linear dextrin.

[0140] 2) Grading of linear dextrins

[0141] LDs were fractionated by alcohol-alcohol precipitation gradient precipitation. Briefly, absolute ethanol was slowly added to the LD dispers...

Embodiment 2

[0154] 1) Preparation of linear dextrin (LD)

[0155] 20g waxy corn starch is configured into starch milk with a mass fraction of 5wt%, placed in a boiling water bath and stirred for 1h to completely gelatinize the starch, and further place the gelatinized starch in an acetate solution (0.02mol / L, pH = 6) Add 40U α-amylase, perform hydrolysis treatment at 50°C for 2 hours, heat up to 110°C for enzyme inactivation treatment, add 600U pullulanase for debranching treatment for 3.5 hours after cooling to 60°C, and place the reaction solution in the Inactivate the enzyme in a boiling water bath for 15 minutes. The reactant was centrifuged at 4500 g for 20 min, the precipitate was discarded, the supernatant was subjected to rotary evaporation, and vacuum freeze-dried to obtain linear dextrin.

[0156] 2) Grading of linear dextrins

[0157] LDs were fractionated by alcohol-alcohol precipitation gradient precipitation. In brief, absolute ethanol was slowly added to the LD dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com