Bifunctional starch-based composite nanoparticle as well as preparation method and application thereof

A composite nanoparticle and functional technology, which is applied in the field of starch deep processing, can solve the problems of limited industrial application and poor stability of double emulsions, and achieve suitable wettability, good emulsification and interface stability, and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

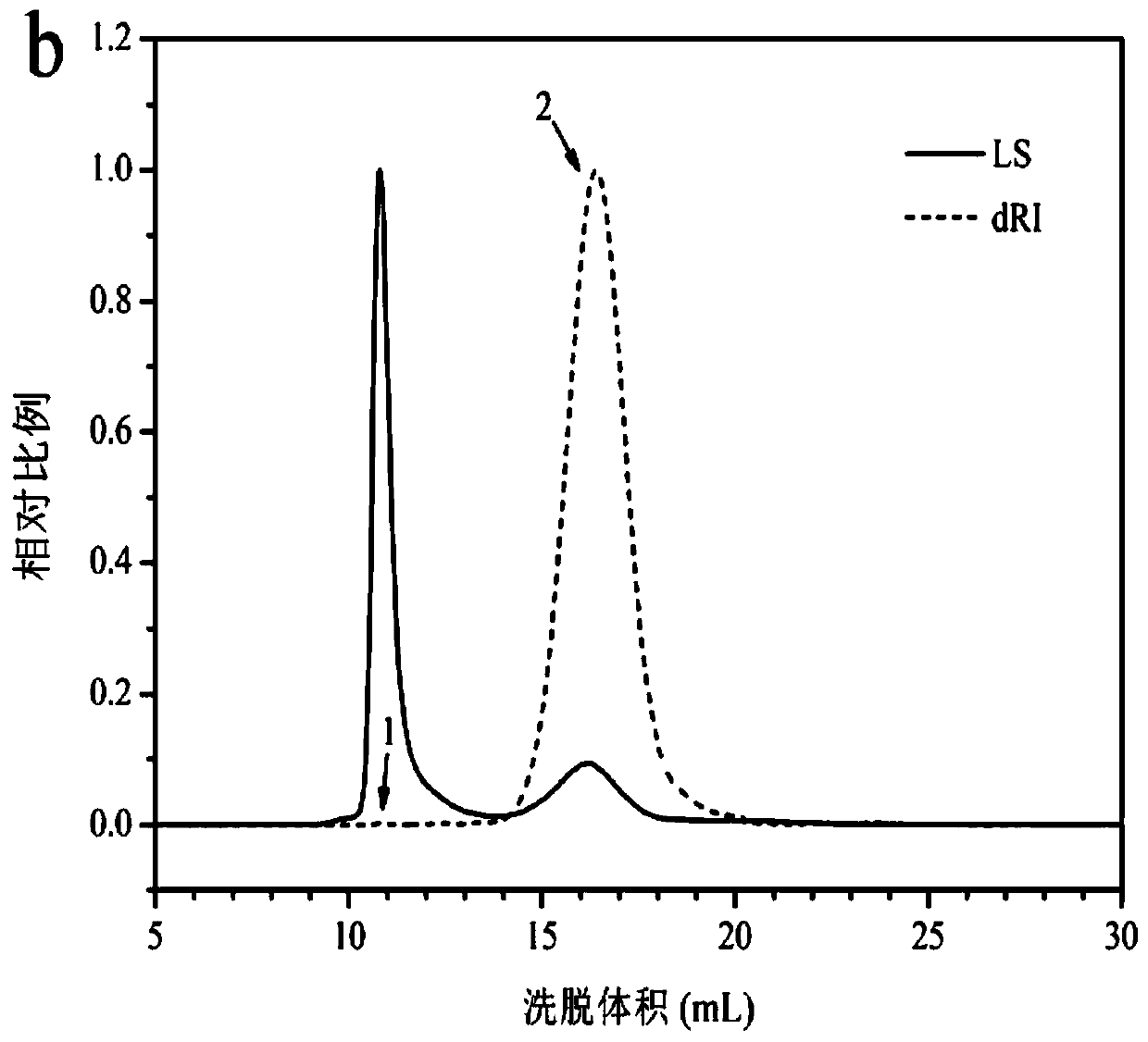

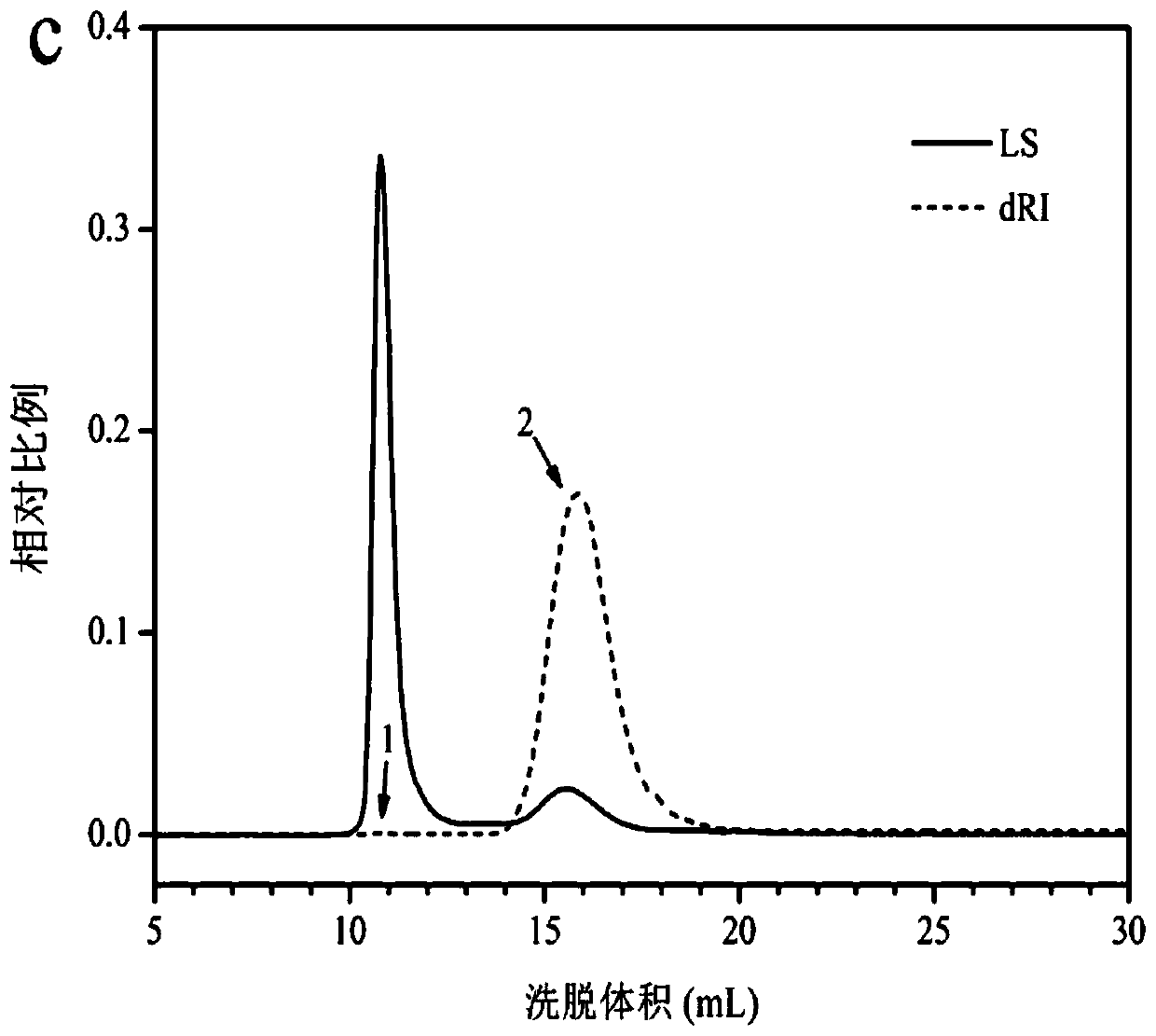

[0050] One aspect of the embodiments of the present invention provides a method for preparing bifunctional starch-based composite nanoparticles, which includes:

[0051] Perform hydrolysis treatment on starch to form starch hydrolyzate and obtain linear dextrin;

[0052] The linear dextrin is classified by an alcohol-alcohol gradient precipitation method to obtain a linear dextrin with uniform molecular weight distribution;

[0053] Oxidizing the linear dextrin by using a TEMPO / NaClO / NaBr oxidation system to obtain oxidized dextrin;

[0054] making the first mixed system comprising oxidized dextrin and curcumin undergo a complex reaction to form an oxidized dextrin-curcumin complex; and,

[0055] Make the oxidized dextrin-curcumin complex and chitosan hydrochloride form oxidized dextrin-curcumin / chitosan hydrochloride composite nanoparticles through electrostatic complexation to obtain the bifunctional starch-based composite nanoparticles.

[0056] In some embodiments, the ...

Embodiment 1

[0138] 1) Preparation of linear dextrin (LD)

[0139] 20g of ordinary cornstarch is configured into starch milk with a mass fraction of 5wt%, placed in a boiling water bath and stirred for 1h to completely gelatinize the starch, and further place the gelatinized starch in an acetate solution (0.02mol / L, with a pH of 6) Add 80U α-amylase, carry out hydrolysis treatment at 60°C for 1.5h, heat up to 100°C for enzyme inactivation treatment, add 1000U pullulanase for debranching treatment at 55°C for 3h, after the reaction, put the reaction solution in Inactivate the enzyme in a boiling water bath for 10 minutes. The reactant was centrifuged at 4500 g for 20 min, the precipitate was discarded, the supernatant was subjected to rotary evaporation, and vacuum freeze-dried to obtain linear dextrin.

[0140] 2) Grading of linear dextrins

[0141] LDs were fractionated by alcohol-alcohol precipitation gradient precipitation. Briefly, absolute ethanol was slowly added to the LD dispers...

Embodiment 2

[0154] 1) Preparation of linear dextrin (LD)

[0155] 20g waxy corn starch is configured into starch milk with a mass fraction of 5wt%, placed in a boiling water bath and stirred for 1h to completely gelatinize the starch, and further place the gelatinized starch in an acetate solution (0.02mol / L, pH = 6) Add 40U α-amylase, carry out hydrolysis treatment at 50°C for 2 hours, heat up to 110°C for enzyme inactivation treatment, add 600U pullulanase for debranching treatment for 3.5 hours after cooling to 60°C, and place the reaction solution in Inactivate the enzyme in a boiling water bath for 15 minutes. The reactant was centrifuged at 4500 g for 20 min, the precipitate was discarded, the supernatant was subjected to rotary evaporation, and vacuum freeze-dried to obtain linear dextrin.

[0156] 2) Grading of linear dextrins

[0157] LDs were fractionated by alcohol-alcohol precipitation gradient precipitation. Briefly, absolute ethanol was slowly added to the LD dispersion u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com