Preparation method of super-hydrophobic graphene wind turbine blade surface protective coating material and product thereof

A technology for protective coatings and wind turbine blades, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as shortened service life of wind turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

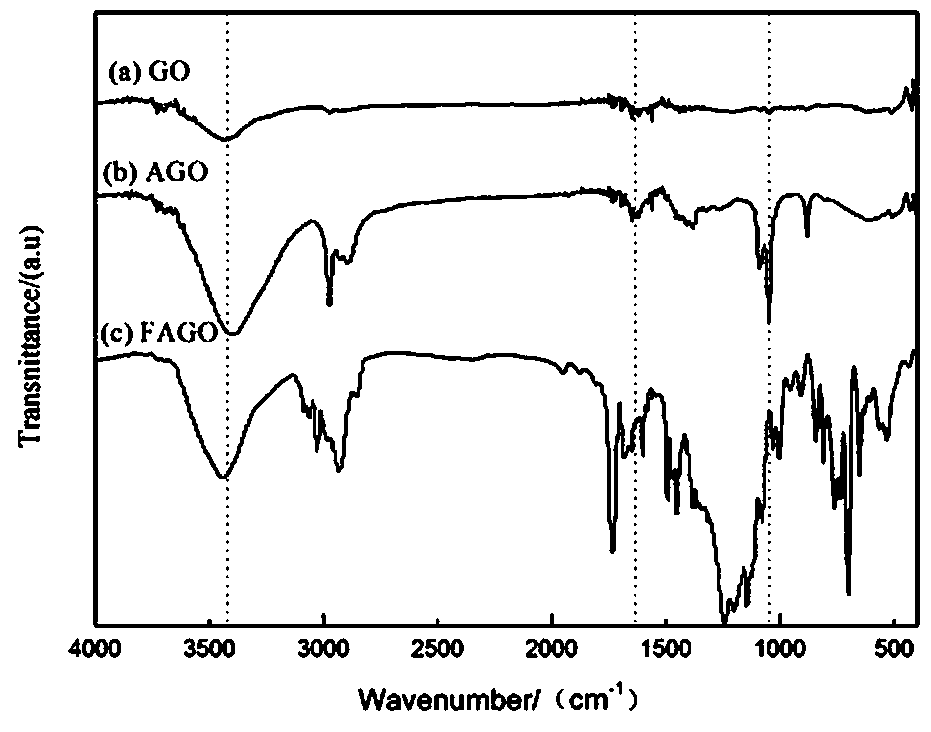

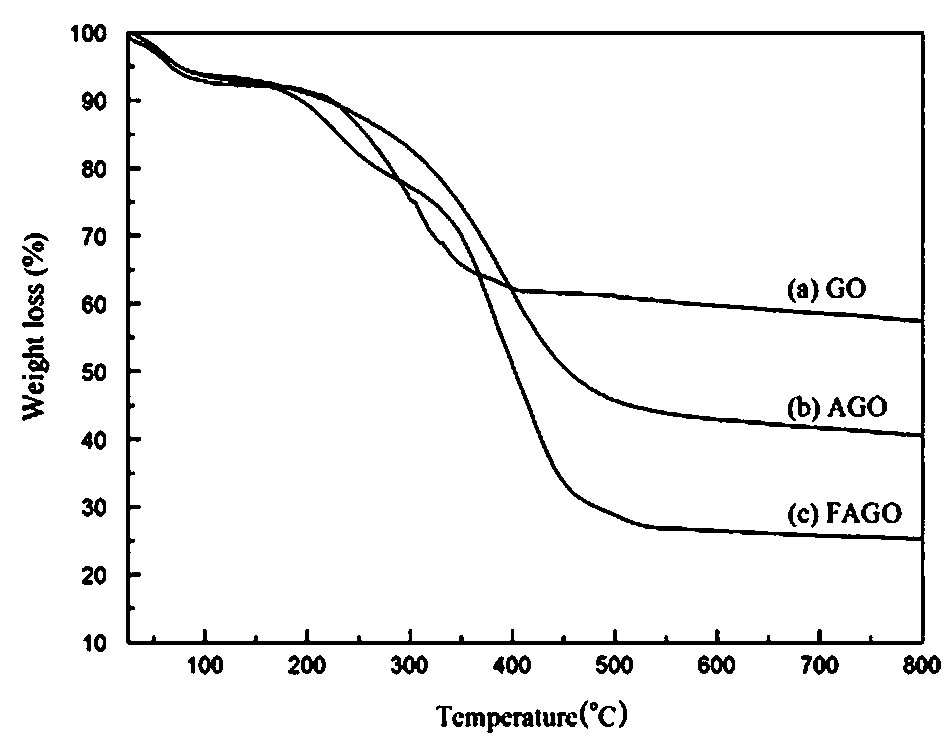

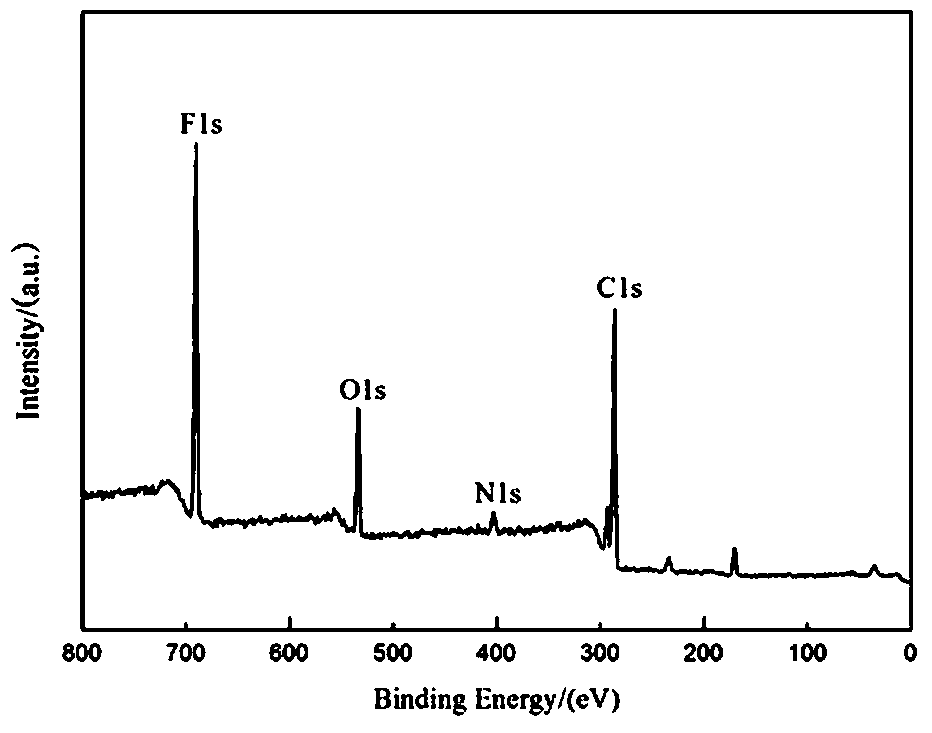

[0025] Put 0.6 g styrene and 2.5 g trifluorooctyl methacrylate monomer in a 100 mL three-necked flask and mix evenly, add 0.03 g azobisisobutylcyanide to the system, and the reaction temperature is 70 o C. The reaction system continued for 10 hours to synthesize styrene / tridecafluorooctyl methacrylate copolymer. Dissolve the styrene / tridecafluorooctyl methacrylate copolymer with an appropriate amount of tetrahydrofuran, precipitate with methanol, wash repeatedly, and dry the precipitate at a constant temperature (60 oC) to a constant weight to obtain a fluorine-containing acrylate binary copolymer for use. Add 1.0 g of flake graphite, 1.2 g of potassium nitrate and 46 mL of concentrated sulfuric acid into a 500 mL four-neck flask and mix evenly. Slowly add 6.0 g of potassium permanganate in an ice-water bath and stir. Then the temperature was raised to 40° C., and the reaction was stirred at high speed for 6 hours. Slowly add 80 mL of distilled water to the reaction system a...

Embodiment 2

[0027] Put 1.1 g of styrene and 2.0 g of trifluorooctyl methacrylate monomer in a 100 mL three-necked flask and mix evenly, add 0.03 g of azobisisobutylcyanide to the system, and the reaction temperature is 70 o C, the reaction system continued for 12 hours to synthesize styrene / tridecafluorooctyl methacrylate copolymer. Dissolve the synthesized styrene / tridecafluorooctyl methacrylate copolymer with an appropriate amount of tetrahydrofuran, precipitate with methanol, wash repeatedly, and dry the precipitate at a constant temperature (60 o C) to a constant weight to obtain a fluorine-containing acrylate binary copolymer for use. Add 1.0 g of flake graphite, 1.2 g of potassium nitrate and 46 mL of concentrated sulfuric acid into a 500 mL four-neck flask and mix evenly. Slowly add 6.0 g of potassium permanganate in an ice-water bath and stir. Then the temperature was raised to 40° C., and the reaction was stirred at high speed for 6 hours. Slowly add 80 mL of distilled water to...

Embodiment 3

[0029] Put 2.2 g of styrene and 1.0 g of trifluorooctyl methacrylate monomer in a 100 mL three-necked flask and mix evenly, add 0.03 g of azobisisobutylcyanide to the system, and the reaction temperature is 70 o C, the reaction system continued for 14 hours to synthesize styrene / tridecafluorooctyl methacrylate copolymer. Dissolve styrene / tridecafluorooctyl methacrylate copolymer with an appropriate amount of tetrahydrofuran, precipitate with methanol, wash repeatedly, and dry the precipitate at constant temperature (60 o C) to a constant weight to obtain a fluorine-containing acrylate binary copolymer for use. Add 1.0 g of flake graphite, 1.2 g of potassium nitrate and 46 mL of concentrated sulfuric acid into a 500 mL four-neck flask and mix evenly. Slowly add 6.0 g of potassium permanganate in an ice-water bath and stir. Then the temperature was raised to 40° C., and the reaction was stirred at high speed for 6 hours. Slowly add 80 mL of distilled water to the reaction syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com