A treatment process for treating high-concentration industrial wastewater using pure microorganisms

A technology for microbial treatment and industrial wastewater, applied in biological water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc. The effect of reducing odor and reducing the amount of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

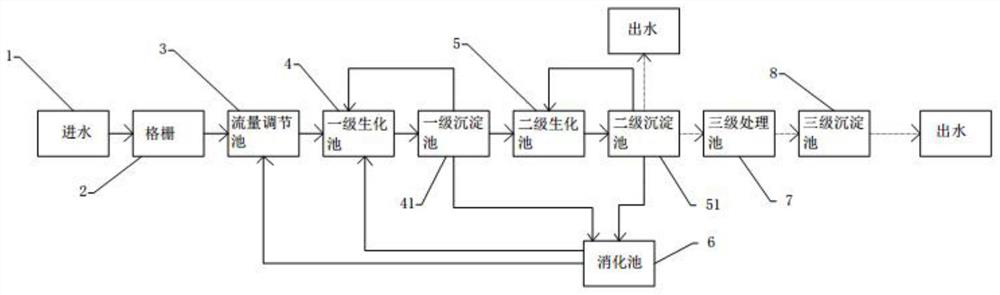

[0024] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0025] see figure 1, a new type of wastewater treatment process using pure microorganisms to treat high-concentration industrial wastewater, including a grid 1, a grit chamber 2, a flow regulating tank 3, a primary biochemical pool 4, a primary sedimentation tank 41, a secondary biochemical pool 5, Secondary sedimentation tank 51 and sludge digestion tank (Sludge Digestion tank) 6; waste water first passes through grid 1 and grit chamber 2 to remove insoluble solids, including large solids, dander, hair and floating debris, and then flows into flow regulation Pond 3 carries out preliminary treatment, then flows into primary biochemical pool 4 to carry out primary biochemical treatment, then flows into primary sedimentation tank 41 to carry out mud-water separation treatment for the first time, and the supernatant liquid of mud-water separation treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com