Mobile phone self-charging system based on friction nano-generator

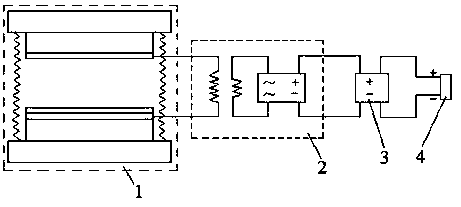

A nano-generator and self-charging technology, which is applied in friction generators, battery circuit devices, current collectors, etc., can solve the problem that it is difficult to meet the needs of charging mobile electronic devices anytime and anywhere, and it is difficult to completely solve the problems of charging mobile electronic devices anytime and anywhere , to achieve the effect of simple structure, low cost and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] Preparation of the first electrode layer 7: Take the aluminum sheet, chemically etch one end face of the aluminum sheet with hydrochloric acid with a concentration of 7% for 2 minutes, and then use 1H, 1H, 2H, 2H-perfluorodecane with a mass concentration of 0.8wt% The base trichlorosilane-toluene solution was modified at room temperature for 12h, and a self-assembled superhydrophobic polymer layer based on the aluminum matrix was formed on the end face of the aluminum sheet. The contact angle of water droplets on the surface of the superhydrophobic polymer layer could reach 151°. The superhydrophobic polymer layer is the second friction layer 13 . The rest of the aluminum flakes are used as electrodes. That is to say, the first electrode layer 7 serves not only as an electrode layer, but also as a friction layer carrier.

[0015] The second friction layer 13 is arranged face to face with the first friction layer 9 .

[0016] The elastic member 8 adopts a spring, prefe...

Embodiment 1

[0028] Cut an aluminum sheet with a diameter of 50mm and a thickness of 0.3mm, chemically etch and modify with 1H,1H,2H,2H-perfluorodecyltrichlorosilane, and form a self-assembled superhydrophobic layer based on an aluminum matrix on one end of the aluminum sheet. The molecular layer (that is, the second friction layer 13 ) is made into the first electrode layer 7 . Cut an elastic sponge with a diameter of 50mm and a thickness of 3mm, stick the first electrode layer 7 closely on the elastic sponge, and the second friction layer 13 is away from the elastic sponge; then cut the size to be 60mm×60mm×2mm (length, width and thickness) of the acrylic sheet, and reserve a spring connection hole with a diameter of 8mm at the four corners of the acrylic sheet, and then stick the acrylic sheet tightly to the other side of the elastic sponge. Cut a polydimethylsiloxane sheet with a diameter of 50mm and a thickness of 0.03mm, and paint a silver paste with a thickness of 0.1mm on the back ...

Embodiment 2

[0031]Cut an aluminum sheet with a diameter of 50mm and a thickness of 0.3mm, chemically etch and modify with 1H, 1H, 2H, 2H-perfluorodecyltrichlorosilane, and form a self-assembled superhydrophobic polymer based on an aluminum matrix on the surface of the aluminum sheet layer (ie, the second friction layer 13 ) to make the first electrode layer 7 . Cut an elastic sponge with a diameter of 50 mm and a thickness of 3 mm, stick the first electrode layer 7 closely on the elastic sponge, and the second friction layer 13 is away from the elastic sponge; then cut the size to be 60 mm×60 mm×2 mm (length , width and thickness) of the acrylic sheet, and reserve a spring connection hole with a diameter of 8mm at the four corners of the acrylic sheet, and then stick the acrylic sheet tightly to the other side of the elastic sponge. Cut a polydimethylsiloxane sheet with a diameter of 50 mm and a thickness of 0.15 mm, and paint a silver paste with a thickness of 0.1 mm on its back as an el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com