Sandwich-shaped hollow spherical lithium ion battery anode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unstable electrochemical performance and high cost, improve electrochemical performance, improve conductivity, and improve point-to-point effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Graphene oxide (GO) was prepared by the modified Hummers method. 2 grams of graphite and 2 grams of potassium nitrate (KNO 3 ) was placed in a three-necked flask, and the flask was placed in an ice-water bath at 0°C, and 96 milliliters of concentrated sulfuric acid (H 2 SO 4 , 96-98wt%). After mixing and stirring evenly, slowly add 12 grams of potassium permanganate (KMnO 4 ), reacted for 90 minutes. After the low-temperature reaction was completed, the temperature was raised to 35° C., and after stirring at a constant temperature for 2 hours, 80 milliliters of deionized water was slowly added dropwise to the mixture, and then 200 milliliters of deionized water and 10 milliliters of hydrogen peroxide (H2O2) were added successively. 2 o 2 aqueous solution, the mass percentage of hydrogen peroxide is 30%), stirred for 20 minutes. After the reaction was cooled, 60 milliliters of hydrochloric acid (aqueous hydrogen chloride solution, 30% by mass of hydrogen chlori...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that the reduced graphene oxide hollow sphere (Hs-rGO) described in step 4), tungsten chloride (WCl 6 ) (wherein the molar ratio of carbon: tungsten is 2:1) and 1.6904 g of thioacetamide (TAA) were dissolved in 25 ml of deionized water, ultrasonicated for 1 hour, and magnetically stirred for 30 minutes; then transferred to a 50 ml stainless steel reaction kettle at 200 ° C Keep it warm for 24 hours and cool down to room temperature naturally. Other steps are identical with embodiment 1.

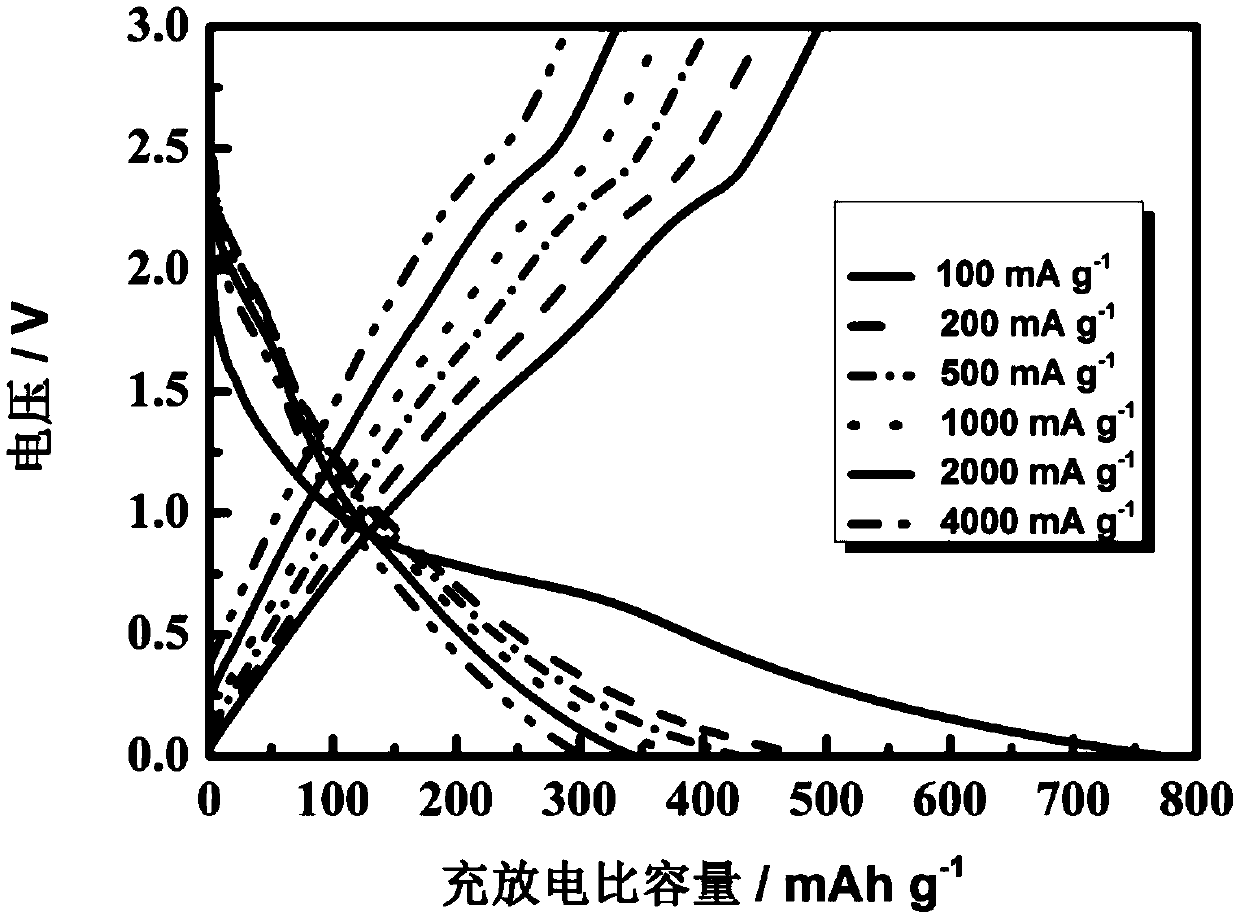

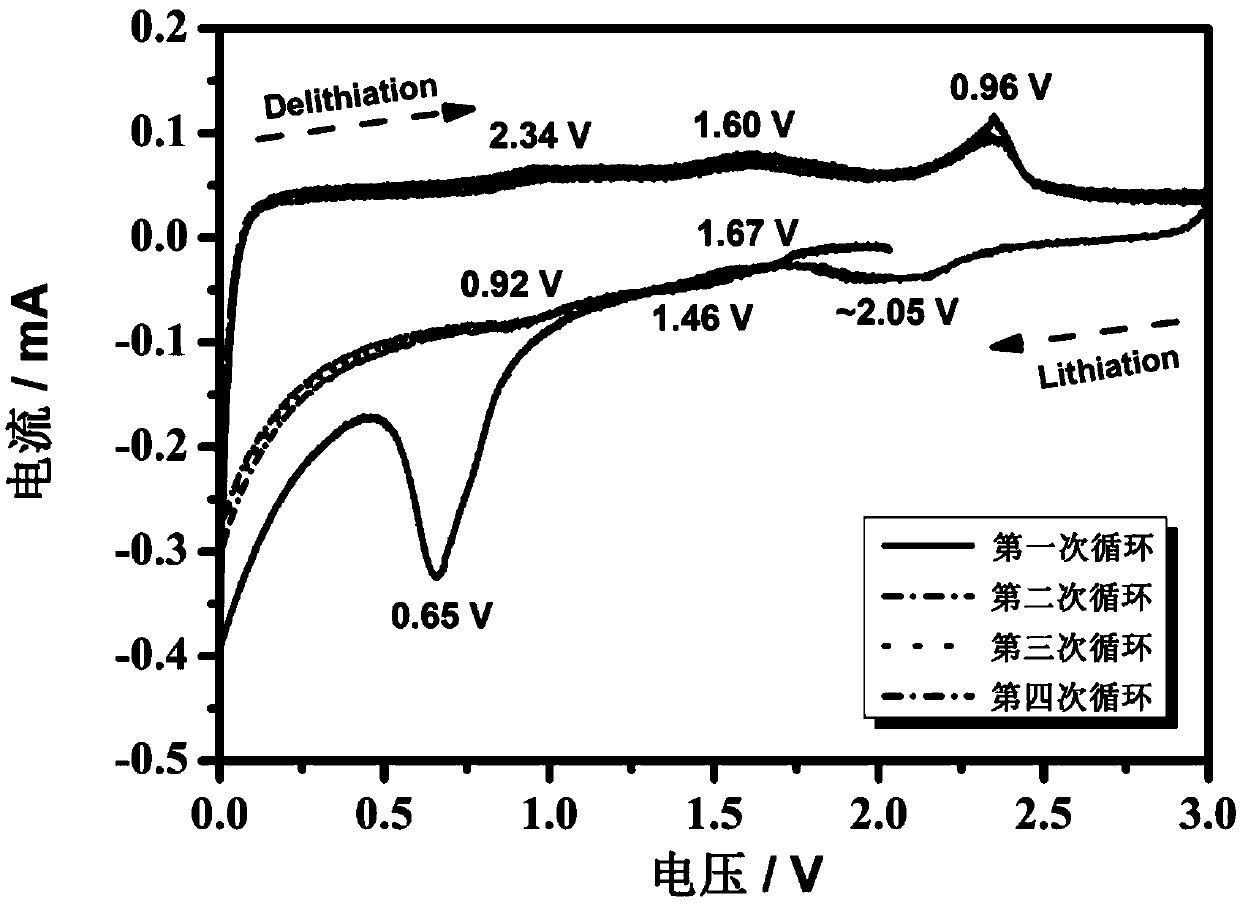

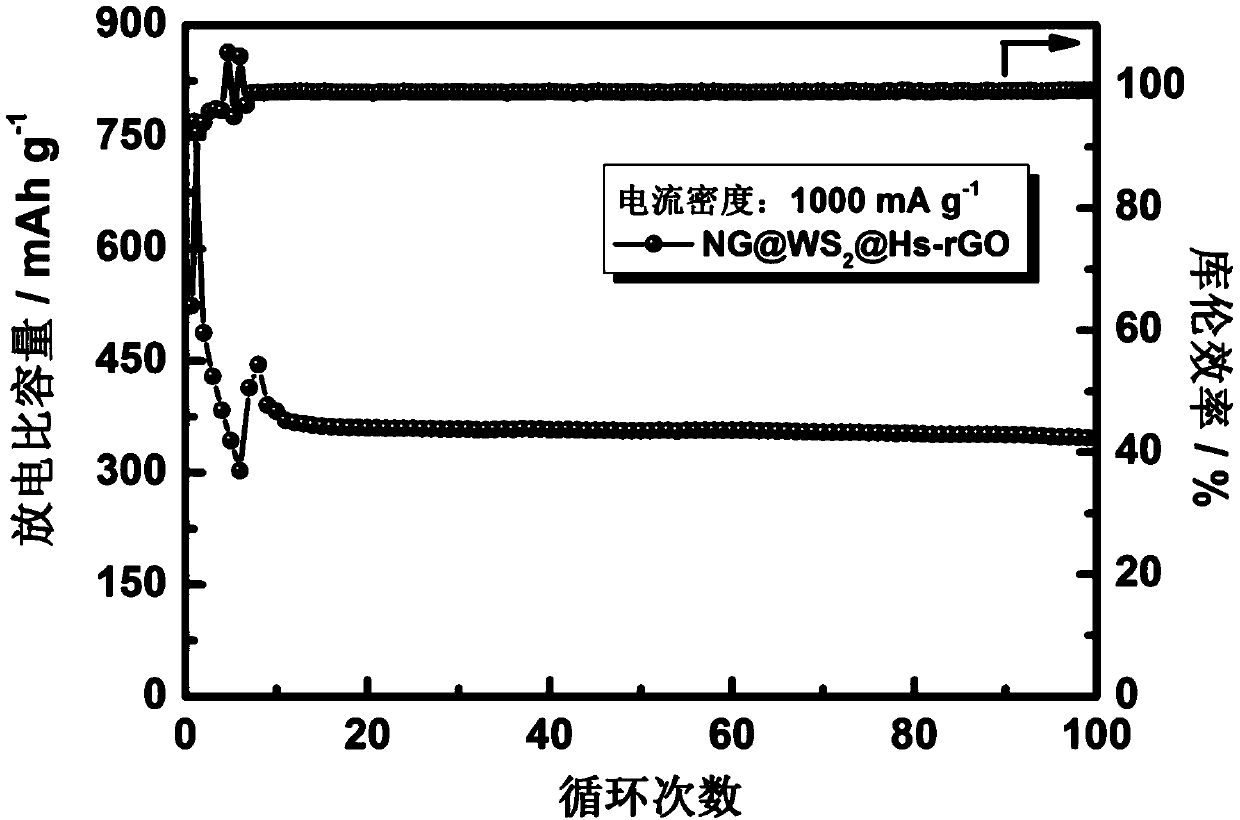

[0049] will attach image 3 -6 is compared, NG@WS in embodiment 1 2 Under the current density of 1000 mA / g of @Hs-rGO material, the discharge capacity of the electrode material after 100 cycles can still reach 346.3 mAh / g, and the discharge capacity of the electrode material in Example 2 after 100 cycles It can still reach 348.7 mAh / g; NG@WS in Example 2 2 Rate curves of the @Hs-rGO material at different current densities. Und...

Embodiment 3

[0051] The difference between embodiment 3 and embodiment 1 described reduced graphene oxide hollow sphere (Hs-rGO), tungsten chloride (WCl 6 ) (the carbon: tungsten molar ratio is 4:1) and 1.6904 g of thioacetamide (TAA) were dissolved in 25 ml of deionized water, ultrasonicated for 1 hour, and magnetically stirred for 30 minutes; then transferred to a 50 ml stainless steel reaction kettle at 200 ° C Keep it warm for 24 hours and cool down to room temperature naturally. Other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com