Device and method for testing frost heaving stress and release characteristics thereof of porous asphalt mixture

A technology for asphalt mixture and frost heave, which is applied in measurement devices, analysis of suspensions and porous materials, and measurement of force, etc., can solve the problem of no unified standard method, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

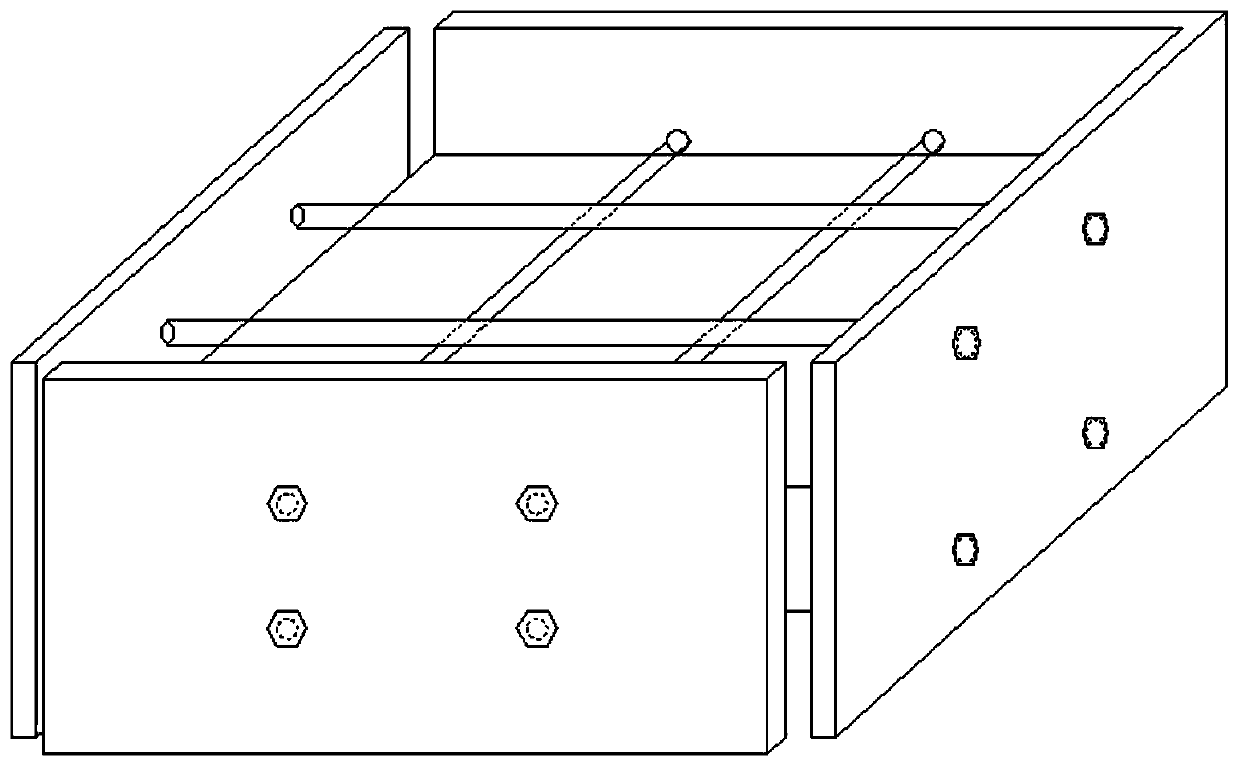

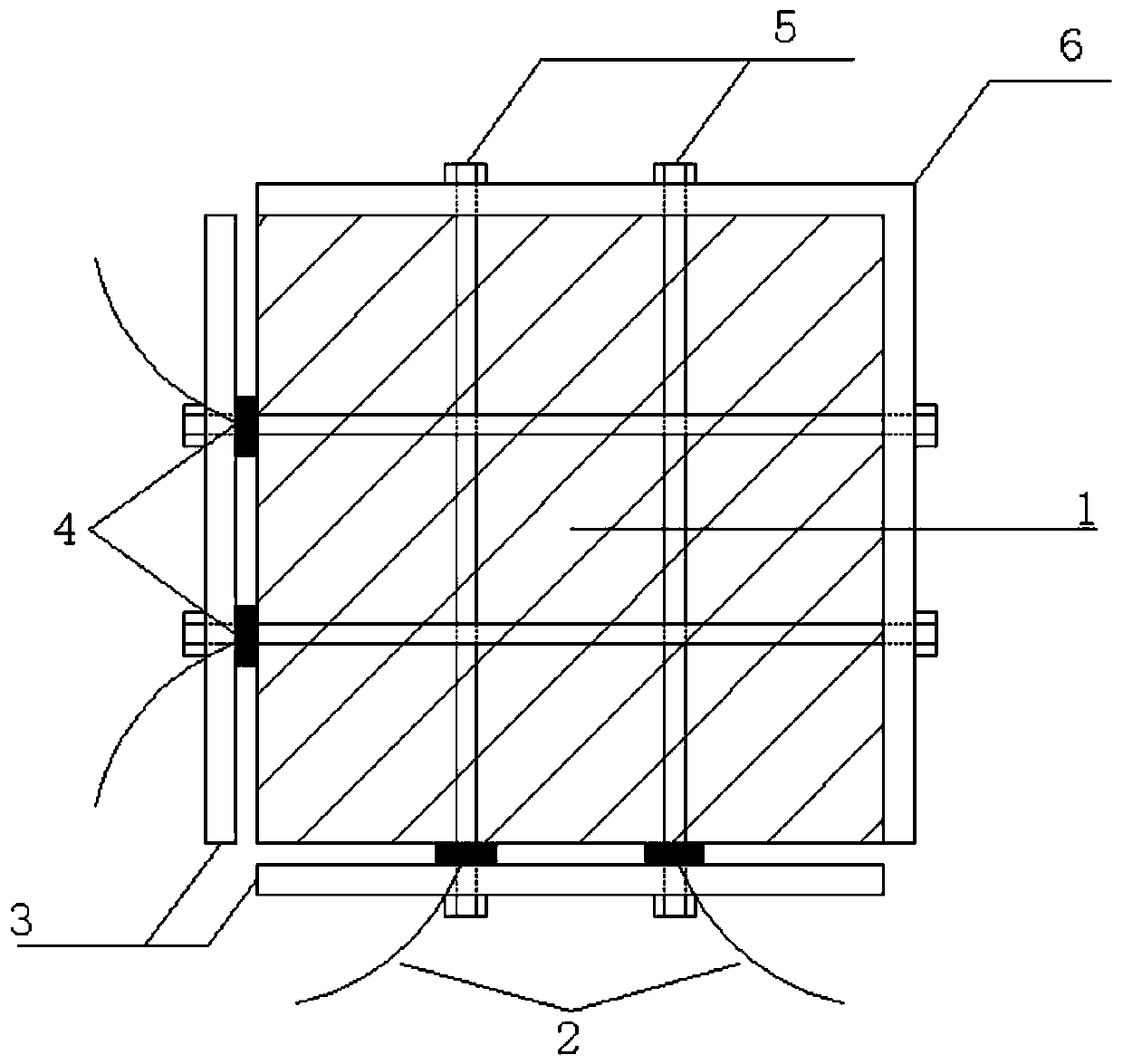

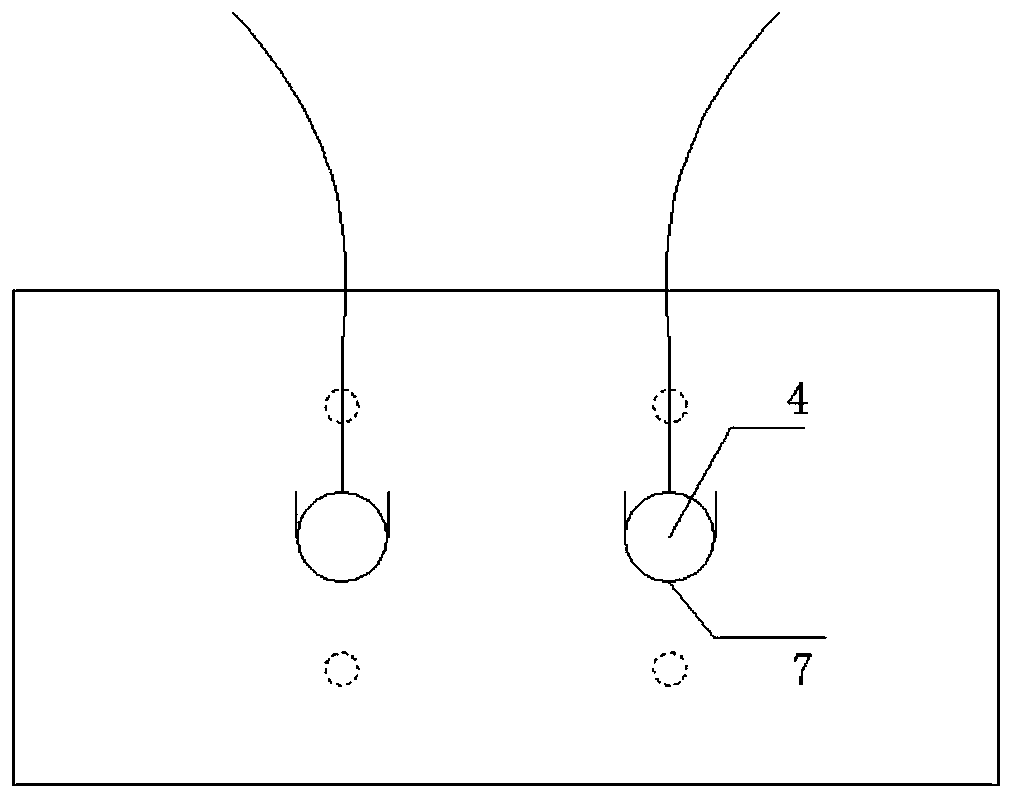

Method used

Image

Examples

Embodiment

[0042] The device and method can be applied not only to porous asphalt mixtures, but also to research on the frost heave stress and release characteristics of porous cement mixtures.

[0043] In the following, the test method of the frost heave stress and release characteristics of the porous cement mixture rut board is described as an example. The test piece used in the examples is a porous cement mixture rut board, and its mixing ratio and void ratio are shown in Table 1.

[0044] Table 1 The mixing ratio and void ratio of the porous cement mixture used in the embodiment

[0045]

[0046] Form the porous cement mixture rut plate specimen (hereinafter referred to as the specimen) according to the mixing ratio of Table 1, and cure it under standard curing conditions for 28 days. Use a vernier caliper to measure the rut plate specimen length 30cm, width 30cm, height 5cm, and calculate the rut board The volume of the test piece is 4500cm 3 .

[0047] Wrap the bottom and sides of the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com