Visual detection system of bimetal composite pipe

A bimetallic composite pipe and detection system technology, which is applied in the field of visual detection devices for bimetallic composite pipes, can solve the problems of liner deformation, oil and gas field pipeline corrosion, and high detection costs, so as to reduce equipment downtime, reduce detection costs, and improve The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

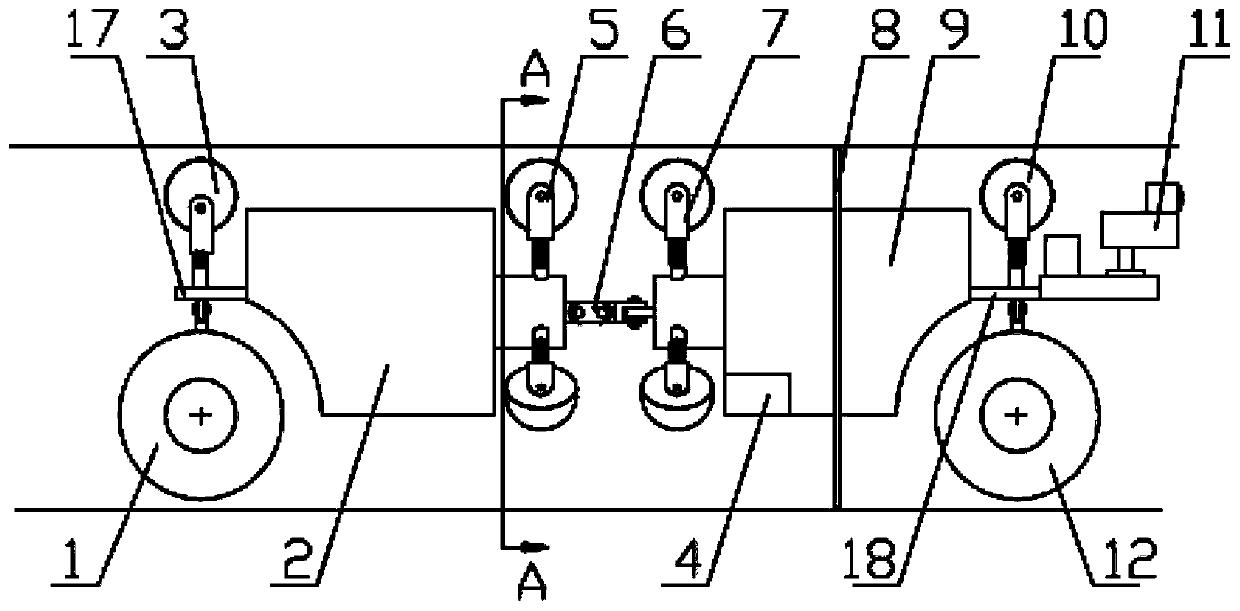

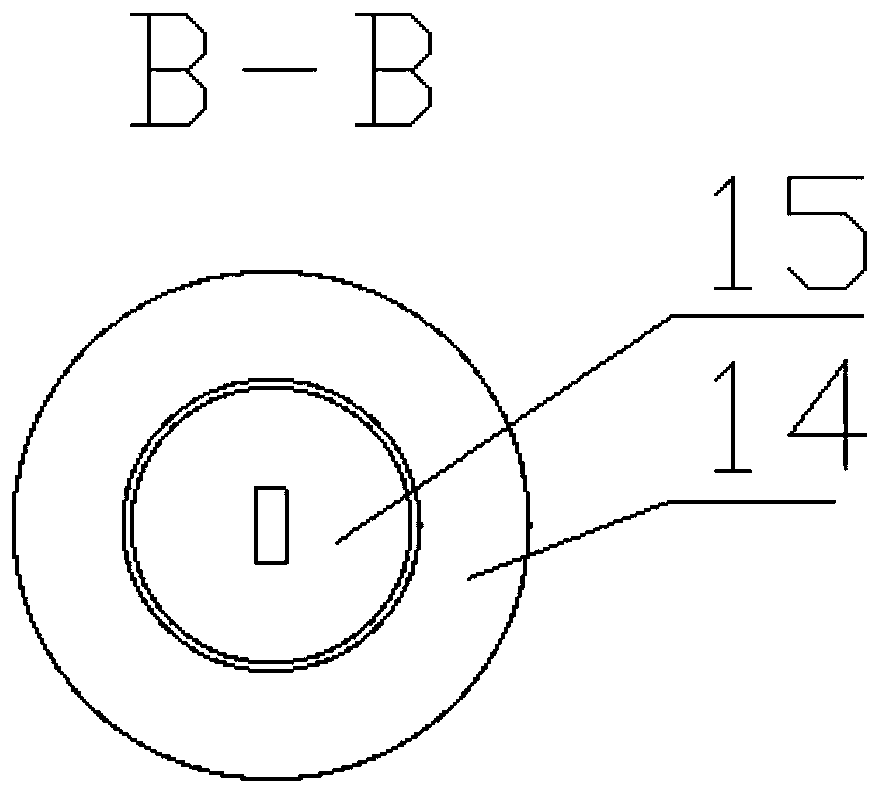

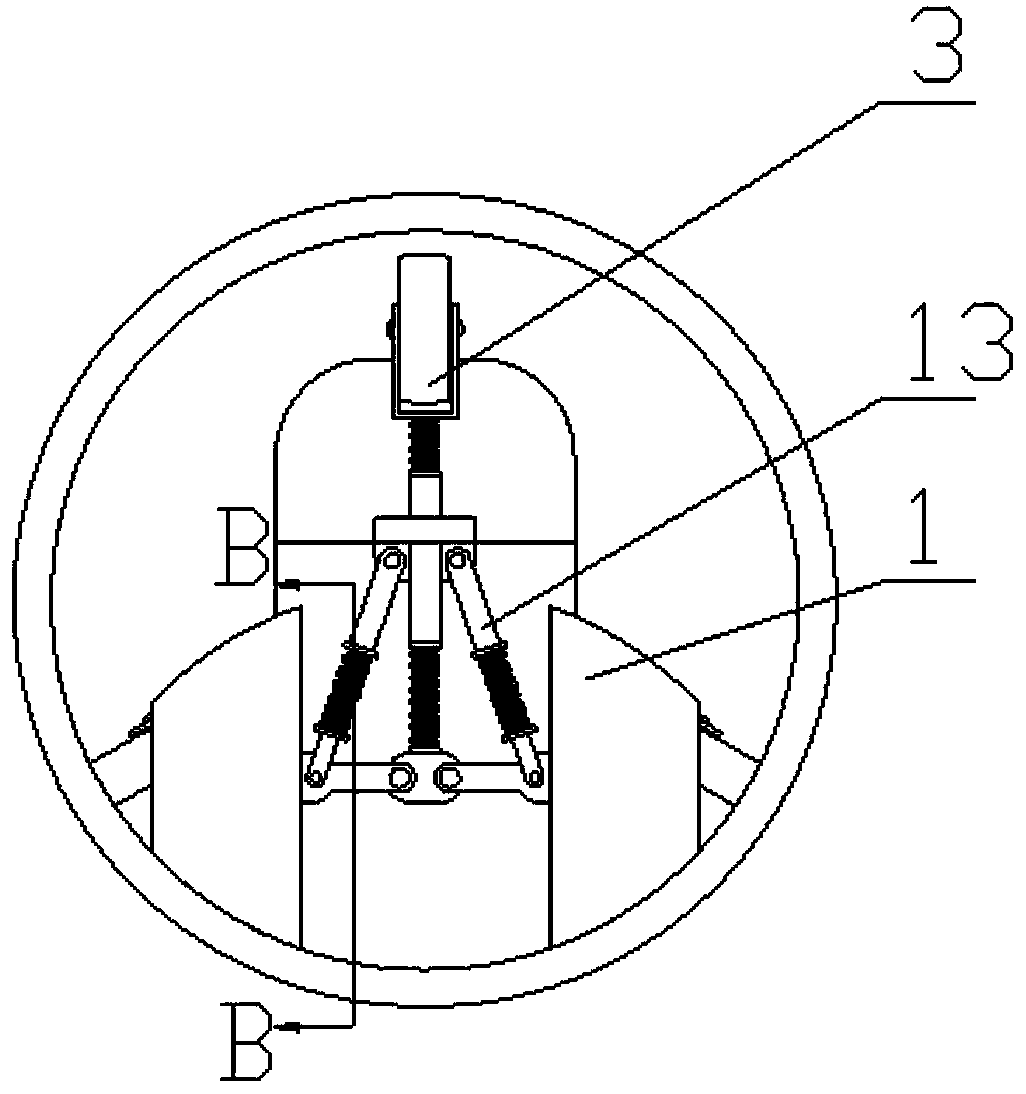

[0021] Hereinafter, the visual inspection system for a bimetallic composite pipe of the present invention will be described in detail in combination with exemplary embodiments.

[0022] In an exemplary embodiment of the present invention, the bimetal composite pipe visual detection system may include a first warehouse body, a first vehicle frame, a first drive unit, a first battery, a first support guide wheel set, and a signal receiving and sending device , a camera component, a deformation sensing component, a positioning unit and a remote controller.

[0023] The left and right ends of the first warehouse body are respectively connected with the first supporting guide wheel set and the first vehicle frame. For example, the right end of the first warehouse body is fixedly connected to the first vehicle frame, and the left end thereof is fixedly connected to the first supporting and guiding wheel set, so that the three form a series structure. The first compartment body can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com