Method and control apparatus for operating reciprocating piston type internal combustion engine

A technology of reciprocating pistons and internal combustion engines, applied in engine control, internal combustion piston engines, combustion engines, etc., can solve problems such as reducing full-load lubrication, and achieve the effects of reducing CO2 emissions, water consumption, and fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

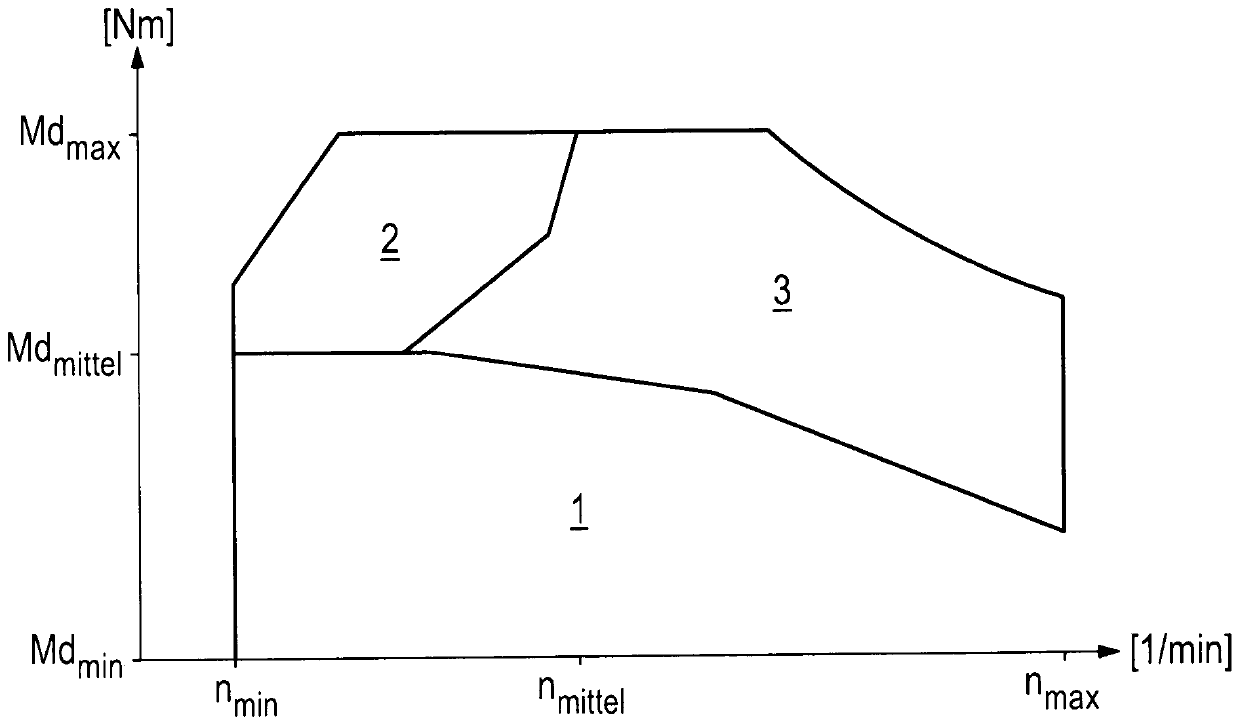

[0025] figure 1 Typical operating characteristic curves for a reciprocating internal combustion engine are shown graphically. On the Y-axis the torque M of the internal combustion engine is shown d (unit is Nm). The rotational speed n of the internal combustion engine (in 1 / min) is shown on the X-axis. The characteristic curve is divided into three approximate regions.

[0026] The first zone 1 from the minimum speed n of the reciprocating internal combustion engine min Extended up to the maximum rotational speed n of the reciprocating internal combustion engine max and from the minimum torque Md min Extend approximately until medium torque Md mittel .

[0027] In the diagram, the second zone 2 is approximately from the medium torque Md mittel Extended up to the maximum torque Md max And from the minimum speed n min Extend approximately up to medium rpm n mittel .

[0028] In the diagram, the third zone 3 is approximately from medium speed n mittel Extended up to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com