Construction method and structure of holing, reinforcing and leaking preventing of old pool side wall

A technology for pools and pool walls, applied in building construction, building maintenance, building types, etc., can solve the problems of not fully meeting the safety standard of leakage prevention, disadvantageous sidewall seepage prevention, leakage prevention, and inability to fully bond, etc. Achieve the effect of small amount of engineering, small opening, and improved anti-seepage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

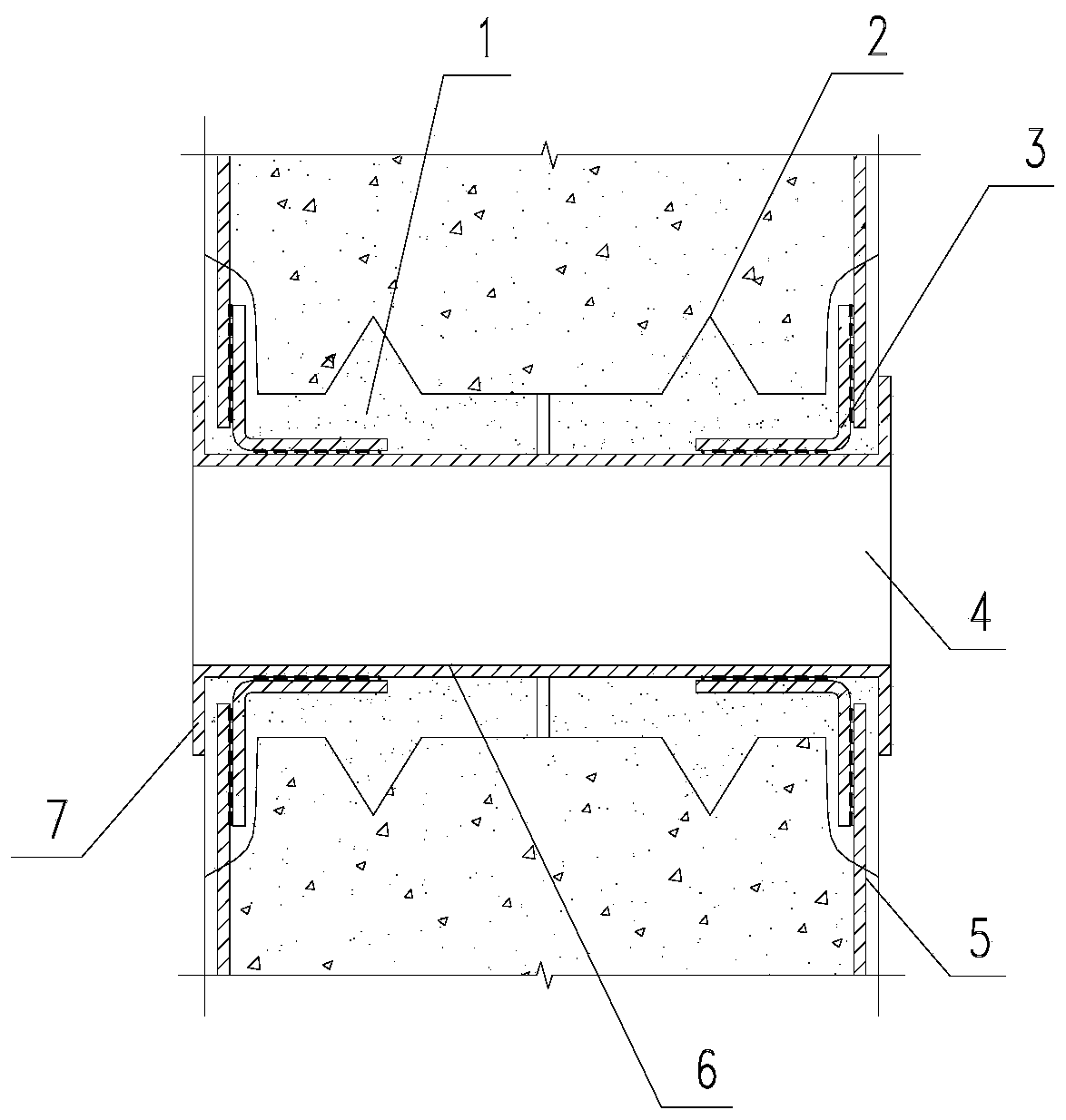

[0028] In a large-scale steel factory wastewater recycling advanced treatment project, in order to reduce engineering investment, the old pool needs to be used for renovation. It is necessary to open a hole in the side wall of the old pool. The inner diameter of the tube 6 is 200 mm). First, the construction workers drilled a hole in the side wall of the old pool, and the radius of the hole was 70 mm larger than the radius of the steel waterproof casing 6 . Cut out the concrete on the pool wall at both ends of the hole, so that the two ends of the hole are ring-shaped, and leak out the steel bar 5 in the pool wall, and the leakage length of the steel bar 5 in the pool wall is 180mm. Then chisel out two V-shaped ring grooves 2 on the hole inwall. Then insert the steel waterproof casing 6 with the water stop ring 7 into the hole, weld the L-shaped steel bars 3 to the steel bars 5 in the pool wall and the steel waterproof casing 6 respectively, and connect the steel waterproof c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com