A kind of solvent-free polyurethane-organosilicon synthetic leather based on UV curing and its manufacturing method

A solvent-free polyurethane and organosilicon synthetic leather technology, applied in textiles and papermaking, etc., to achieve the effect of improving quality and international market competitiveness, high efficiency and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

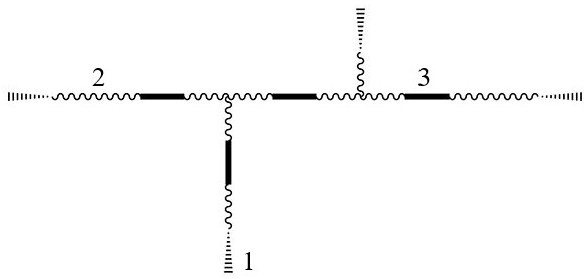

Image

Examples

Embodiment 1

[0030] Manufacture of solvent-free polyurethane-silicon synthetic leather for clothing

[0031] (1) Preparation of UV-curable solvent-free polyurethane:

[0032] After vacuum dehydration, 40 parts of polyadipate-1,3-butylene glycol ester diol with a number average molecular weight of 2000, 15 parts of polypropylene carbonate diol with a number average molecular weight of 1000, and polypropylene glycol with a number average molecular weight of 4000 20 parts and 1.5 parts of 1,4-butanediol were added to the reaction kettle, followed by adding 10 parts of isophorone diisocyanate, 10 parts of hexamethylene diisocyanate, and 0.1 parts of organic bismuth catalyst, and the temperature was raised to 85 °C. After stirring for 1 hour, add 1.0 part of trimethylolpropane, continue stirring and reacting at 85 °C for 1.5 h, then cool down, add β-hydroxyethyl acrylate to block at 60 °C, and measure -NCO group by di-n-butylamine method After the group reaction is complete, the UV-curable sol...

Embodiment 2

[0039] Manufacture of solvent-free polyurethane-silicon synthetic leather for automotive interior

[0040] (1) Preparation of UV-curable solvent-free polyurethane:

[0041] Add 20 parts of polypropylene carbonate diol with a number average molecular weight of 3000 after vacuum dehydration, 30 parts of polypropylene glycol with a number average molecular weight of 2000, and 1.0 parts of 1,4-butanediol into the reactor, and then add diphenyl 15 parts of methane diisocyanate, 0 parts of organic bismuth catalyst, heat up to 75 °C, stir for 1.5 h, add 1.0 parts of trimethylolpropane, continue stirring for 1 h at 75 °C, cool down, add 4-hydroxybutyl vinyl ether End-capping at 55°C, after the reaction of -NCO groups is completely determined by the di-n-butylamine method, a UV-curable solvent-free polyurethane prepolymer containing photosensitive groups in both end groups and side chains is prepared, sealed and packaged for waiting use;

[0042] (2) Preparation of UV-curable slurry:...

Embodiment 3

[0048] Manufacture of Solvent-free Polyurethane-Organosilicon Synthetic Leather for Sofa

[0049] (1) Preparation of UV-curable solvent-free polyurethane:

[0050] Add 45 parts of polypropylene glycol with a number average molecular weight of 2000 after vacuum dehydration and 1.0 part of 1,4-butanediol into the reaction kettle, then add 12 parts of hexamethylene diisocyanate and 0.05 parts of organic bismuth catalyst in sequence, and heat up to 85 ℃, stirred for 1 h, then added 1.0 parts of trimethylolpropane, continued to stir and react for 1 h at 85 ℃, then cooled down, added β-hydroxyethyl methacrylate to block at 60 ℃, and di-n-butylamine Determination by method - after the NCO group is completely reacted, the UV-curable solvent-free polyurethane prepolymer containing photosensitive groups in both the end group and the side chain is prepared, sealed and packaged for use;

[0051] (2) Preparation of UV curable slurry: 80 parts of UV curable solvent-free polyurethane, 20 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com