Semi-solid metal-based hydrolysis hydrogen production material and preparation method thereof

A semi-solid metal and semi-solid technology, applied in the field of metal materials, can solve the problems of low hydrogen conversion rate, insufficient hydrogen production rate, affecting the development and application of metal hydrolysis hydrogen production technology, and achieve the effect of high production capacity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a semi-solid metal-based hydrolysis hydrogen production material, the material is composed of components containing the following mass percentages: 83% of the metal matrix element, 17% of the active element, wherein the metal matrix element is aluminum, The active elements are metal elements Ga, In and Sn.

[0036] The above-mentioned semi-solid metal-based hydrolysis hydrogen production material can be prepared by the following method, and the specific steps are as follows:

[0037] Step 1): Metal matrix elements containing 83wt.% industrial pure aluminum and active elements Ga, In, Sn containing 17wt.% are melted and casted at 700°C to make alloy blanks.

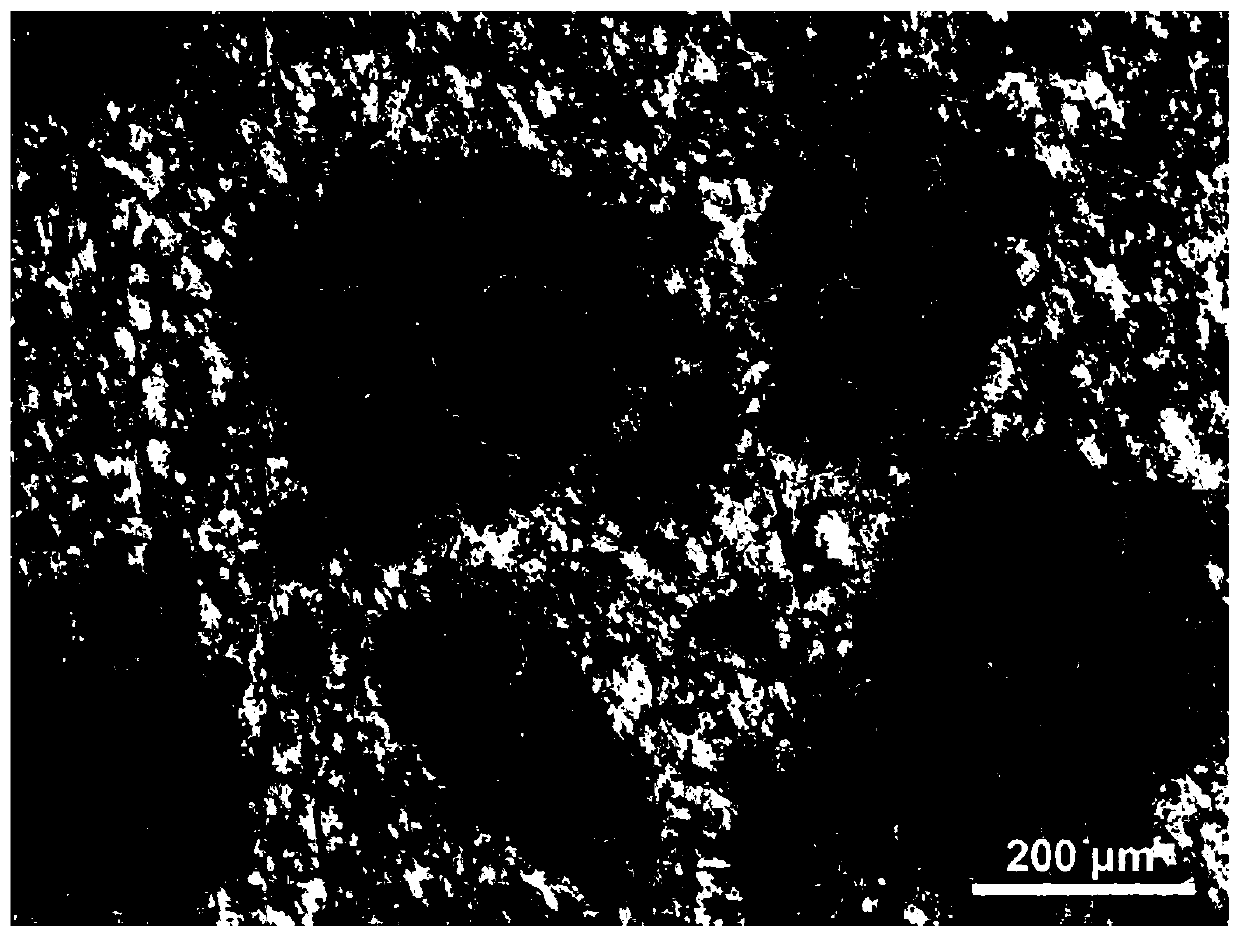

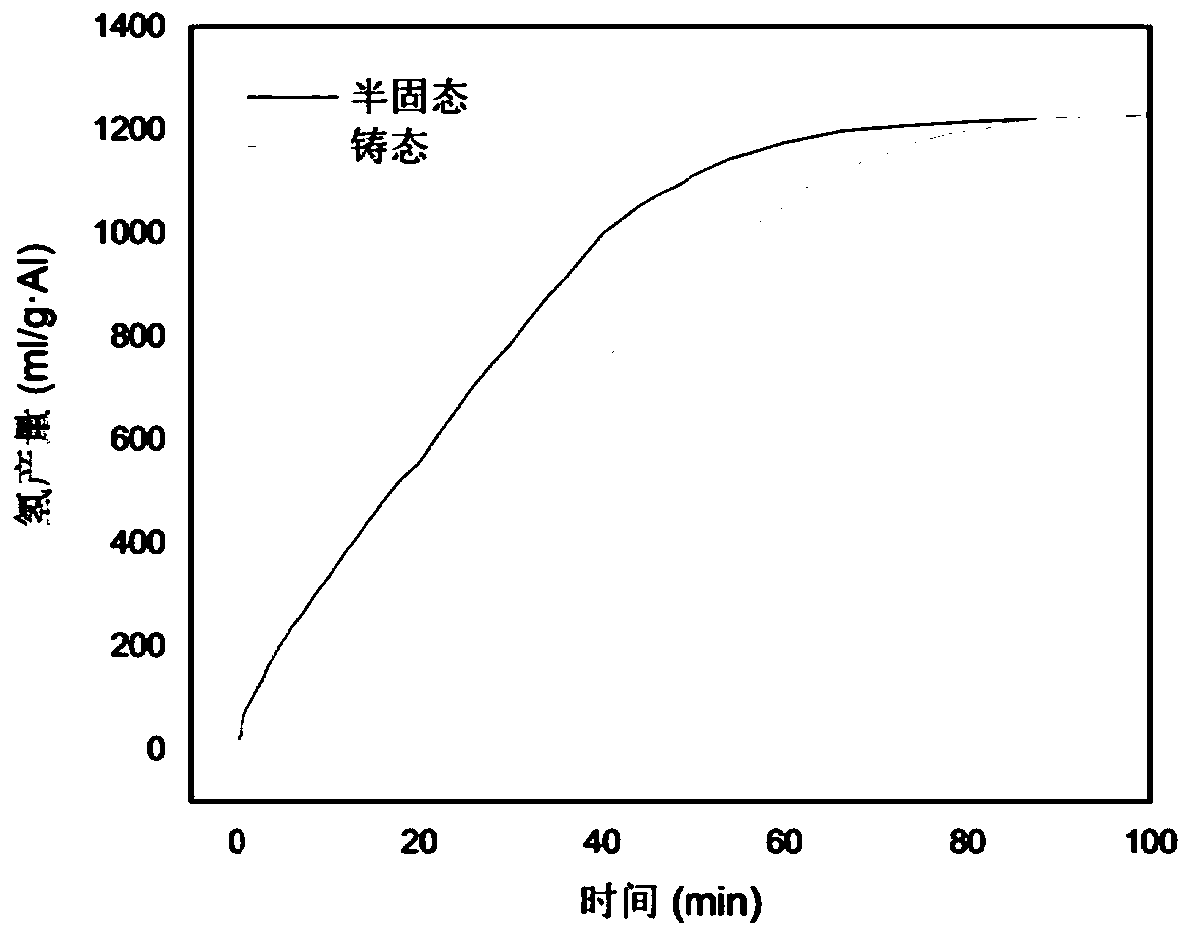

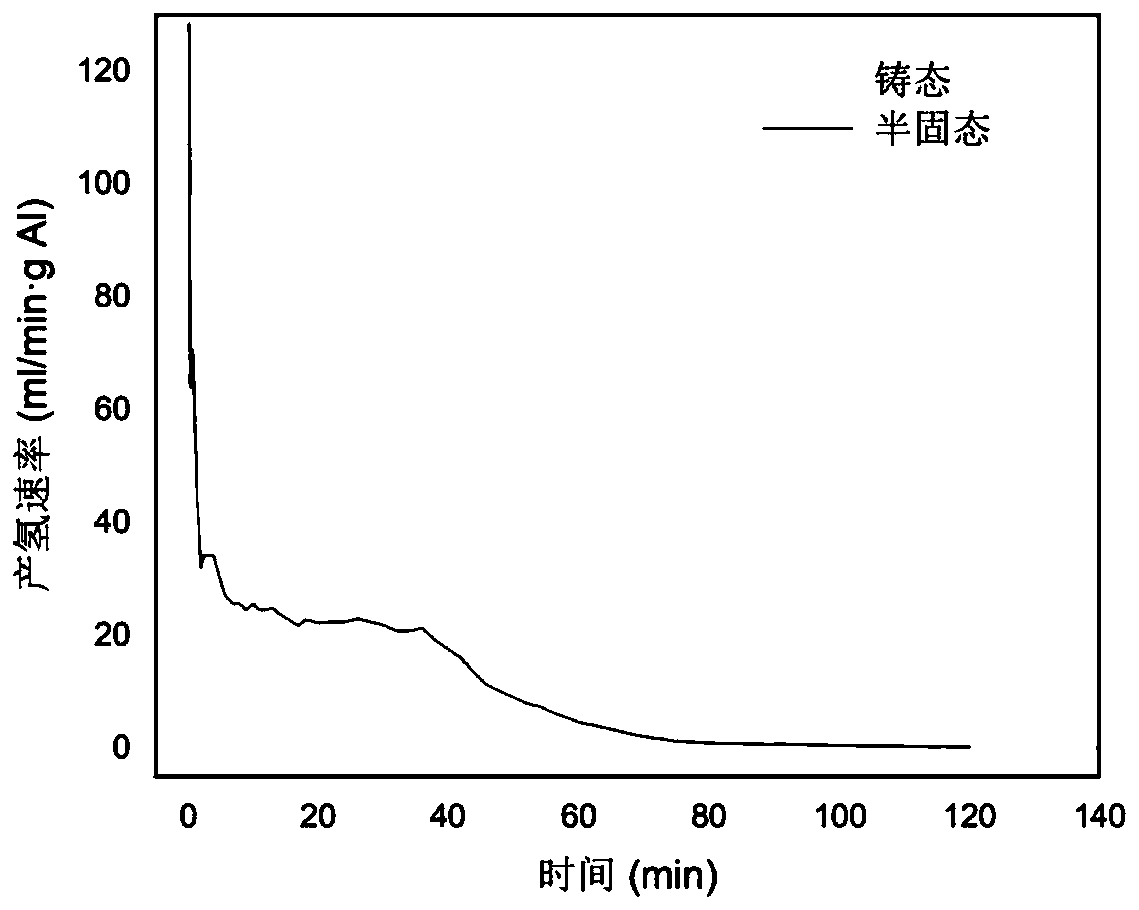

[0038] Step 2): The alloy blank made in step 1) is subjected to semi-solid secondary remelting at 620°C to make slurry, and after cooling, an Al-15wt.%GaInSn semi-solid block hydrolysis hydrogen production material is obtained, and the material has a semi-solid Tissue, in the semi-solid tis...

Embodiment 2

[0043] This example provides a semi-solid metal-based hydrolysis hydrogen production material and its preparation method. Compared with Example 1, this example is different in that the metal matrix element is Mg25wt.%Al alloy, the melting temperature is 680°C, and the second The remelting temperature is 500°C.

[0044] Compared with Example 1, the amount of hydrogen produced is greatly reduced.

Embodiment 3

[0046] This embodiment provides a semi-solid metal-based hydrolysis hydrogen production material, the material is composed of components containing the following mass percentages: 99% of the metal matrix element, 1% of the active element, wherein the metal matrix element is aluminum, The active elements are metal elements Ga, In, Sn and Zn.

[0047] The above-mentioned semi-solid metal-based hydrolysis hydrogen production material can be prepared by the following method, and the specific steps are as follows:

[0048] Step 1): Metal matrix elements containing 99wt.% industrial pure aluminum and 1wt.% active elements Ga, In, Sn and Zn are melted and cast at 720°C to make alloy blanks.

[0049] Step 2): The alloy blank prepared in step 1) is mechanically stirred at 650°C in the semi-solid temperature range for slurrying, and after cooling, an Al-1wt.% (GaInSnZn) semi-solid bulk hydrolysis hydrogen production material is obtained. The material has a semi-solid structure, in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com