Foaming system for air foam flooding and its preparation method and application

An air foam flooding system technology, applied in chemical instruments and methods, mining fluids, earth drilling and mining, etc., can solve the problems of increased construction difficulty, limited plugging capacity, increased construction cost, etc., to reduce construction procedures and operational difficulties , Increased construction cost and strong plugging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

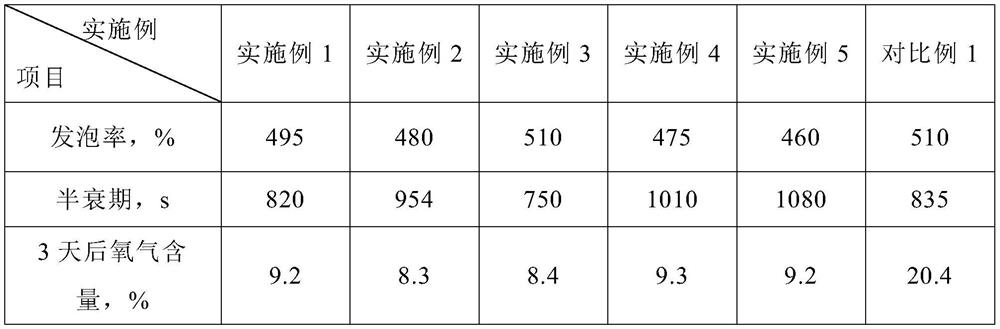

Examples

Embodiment 1

[0049] A foaming system for air foam flooding, the weight percentage of each component is:

[0050] Fatty alcohol polyoxyethylene ether sodium sulfate (carbon number is 12): 10%;

[0051] Sodium α-alkenyl sulfonate (14 carbons): 25%;

[0052] Silicone polyether emulsion: 5%;

[0053] Acetone: 10%;

[0054] Hydroxylamine hydrochloride: 10%;

[0055] The balance is tap water, and the sum of the weight percentages of each component is 100%.

[0056] The preparation method of the foaming system for air foam flooding of the present embodiment specifically comprises the following steps:

[0057] Step 1. Add measured water and acetone to the reaction kettle respectively, and stir evenly;

[0058] Step 2. Slowly add a good amount of hydroxylamine hydrochloride into the solution prepared in step 1, stir while adding, and stir for 1 hour until the hydroxylamine hydrochloride is completely dissolved, and keep the temperature of the reaction kettle at 30°C;

[0059] Step 3. Slowly a...

Embodiment 2

[0062] A foaming system for air foam flooding, the weight percentage of each component is:

[0063] Fatty alcohol polyoxyethylene ether sodium sulfate (carbon number is 14): 20%;

[0064] Sodium α-alkenyl sulfonate (16 carbons): 15%;

[0065] Modified silicone polyether emulsion: 7%;

[0066] Acetone: 12%;

[0067] Hydroxylamine hydrochloride: 13%;

[0068] The balance is tap water, and the sum of the weight percentages of each component is 100%.

[0069] The preparation method of the foaming system for air foam flooding of the present embodiment specifically comprises the following steps:

[0070] Step 1. Add measured water and acetone to the reaction kettle respectively, and stir evenly;

[0071] Step 2. Slowly add a good amount of hydroxylamine hydrochloride into the solution prepared in step 1, stir while adding, and stir for 0.5 hours until the hydroxylamine hydrochloride is completely dissolved, and keep the temperature of the reaction kettle at 32°C;

[0072] Step...

Embodiment 3

[0075] A foaming system for air foam flooding, the weight percentage of each component is:

[0076] Fatty alcohol polyoxyethylene ether sodium sulfate: 30%;

[0077] Silicone polyether emulsion: 2%;

[0078] Acetone: 11%;

[0079] Hydroxylamine hydrochloride: 12%;

[0080] The balance is tap water, and the sum of the weight percentages of each component is 100%.

[0081] The preparation method of the foaming system for air foam flooding of the present embodiment specifically comprises the following steps:

[0082] Step 1. Add measured water and acetone to the reaction kettle respectively, and stir evenly;

[0083] Step 2. Slowly add a good amount of silicone resin polyether emulsion into the solution prepared in step 1, stir while adding, and stir for 1.5 hours until the solution is fully mixed and uniform, and keep the temperature of the reactor at 30°C;

[0084] Step 3. Slowly add a good amount of hydroxylamine hydrochloride into the solution prepared in step 2, stir wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com