Mercaptan -modified epoxy adhesive prepolymer capable of being quickly cured at room temperature, and preparation method thereof

An epoxy adhesive, fast curing technology, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of limited application scope and low viscosity, and achieve the effect of easy purchase in the market, low cost and rich market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

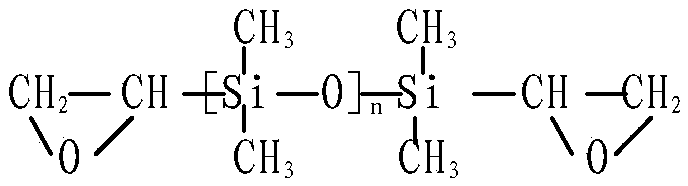

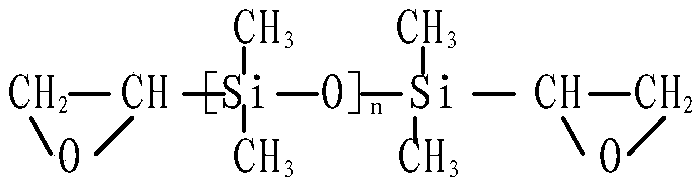

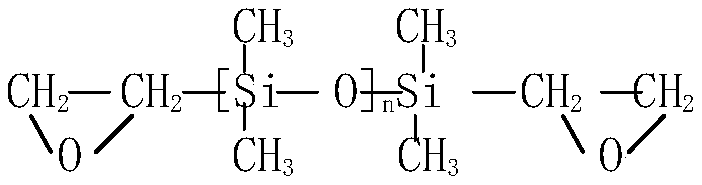

Method used

Image

Examples

Embodiment 1

[0036] A kind of mercaptan modified room temperature rapid curing epoxy adhesive prepolymer and preparation method thereof, the specific steps are as follows:

[0037] (1) Add 990g of pentaerythritol tetrakis(3-mercaptopropionate) and 5g of 2,4,6-tris(dimethylaminomethyl)phenol into the reaction kettle, stir at 15°C for 1h to disperse the two Uniformly, to obtain a mixture;

[0038] (2) Add 10g of 1,6-hexanediol diglycidyl ether to the mixture obtained in step (1), and then carry out vacuum degassing and stirring reaction at 25°C for 3 hours to obtain mercaptan-modified epoxy Resin adhesive prepolymers;

[0039] The mercaptan-modified epoxy resin adhesive prepolymer and epoxy resin were mixed at a mass ratio of 0.68:1 to verify the curing of the adhesive.

[0040] After testing, the thiol-modified epoxy resin adhesive prepolymer provided in Example 1 of the present invention has a mercapto group content of 26.1%, an epoxy value of 0.02, a viscosity of 860mpa*s, and a curing ...

Embodiment 2

[0042] A kind of mercaptan modified room temperature rapid curing epoxy adhesive prepolymer and preparation method thereof, the specific steps are as follows:

[0043] (1) Add 950g of pentaerythritol tetrakis(3-mercaptopropionate) and 5g of 2,4,6-tris(dimethylaminomethyl)phenol into the reaction kettle, stir at 25°C for 1h to disperse the two Uniformly, to obtain a mixture;

[0044] (2) Add 50g of 1,6-hexanediol diglycidyl ether to the mixture obtained in step (1), and then carry out vacuum degassing and stirring reaction at 25°C for 3 hours to obtain thiol-modified epoxy Resin adhesive prepolymers;

[0045] The thiol-modified epoxy resin adhesive prepolymer and epoxy resin were mixed at a mass ratio of 0.72:1 to verify the curing of the adhesive.

[0046]After testing, the thiol-modified epoxy resin adhesive prepolymer provided in Example 2 of the present invention has a mercapto group content of 25.6%, an epoxy value of 0.04, a viscosity of 7860mpa*s, and a curing time of ...

Embodiment 3

[0048] A kind of mercaptan modified room temperature rapid curing epoxy adhesive prepolymer and preparation method thereof, the specific steps are as follows:

[0049] (1) Add 900g of pentaerythritol tetrakis(3-mercaptopropionate) and 10g of 2,4,6-tris(dimethylaminomethyl)phenol into the reaction kettle, stir at 25°C for 1h to disperse the two Uniformly, get the mixture;

[0050] (2) Add 100g of 1,6-hexanediol diglycidyl ether to the mixture obtained in step (1), and then carry out vacuum degassing and stirring reaction at 50°C for 3 hours to obtain thiol-modified epoxy Resin adhesive prepolymers;

[0051] The mercaptan-modified epoxy resin adhesive prepolymer and epoxy resin were mixed at a mass ratio of 0.78:1 to verify the curing of the adhesive.

[0052] After testing, the mercaptan-modified epoxy resin adhesive prepolymer provided in Example 3 of the present invention has a mercapto group content of 25.1%, an epoxy value of 0.06, a viscosity of 13820mpa*s, and a curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com