Toughened PA/ABS alloy material and preparation method thereof

A kind of alloy material, strengthening and toughening technology, applied in the field of strengthening and toughening PA/ABS alloy material and its preparation, can solve the problems of poor compatibility, difficulty in strengthening and toughening, and reduced tensile strength, etc., to achieve bending strength toughening, Resistant to hydrolysis, the effect of reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

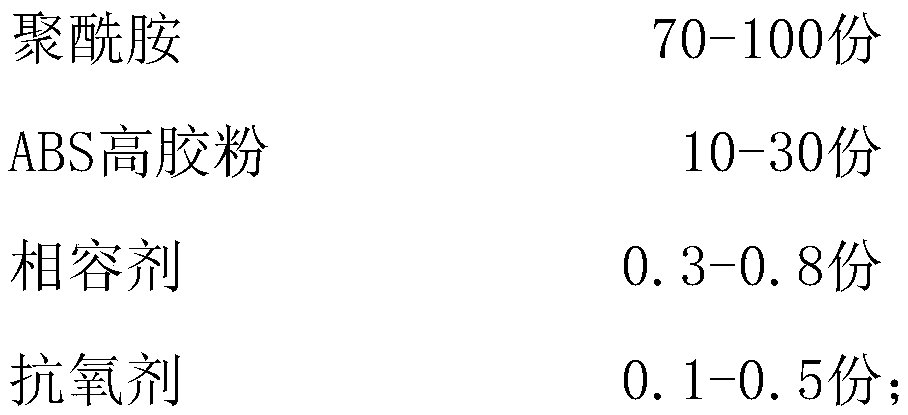

[0039] A toughened PA / ABS alloy material, comprising the following raw materials in parts by weight:

[0040]

[0041] The compatibilizer is an epoxy-type compatibilizer with a long side chain structure.

[0042] The polyamide is PA6.

[0043] The rubber content of the ABS high rubber powder is 60 wt%, and the acrylonitrile content of the ABS high rubber powder is 28 wt%.

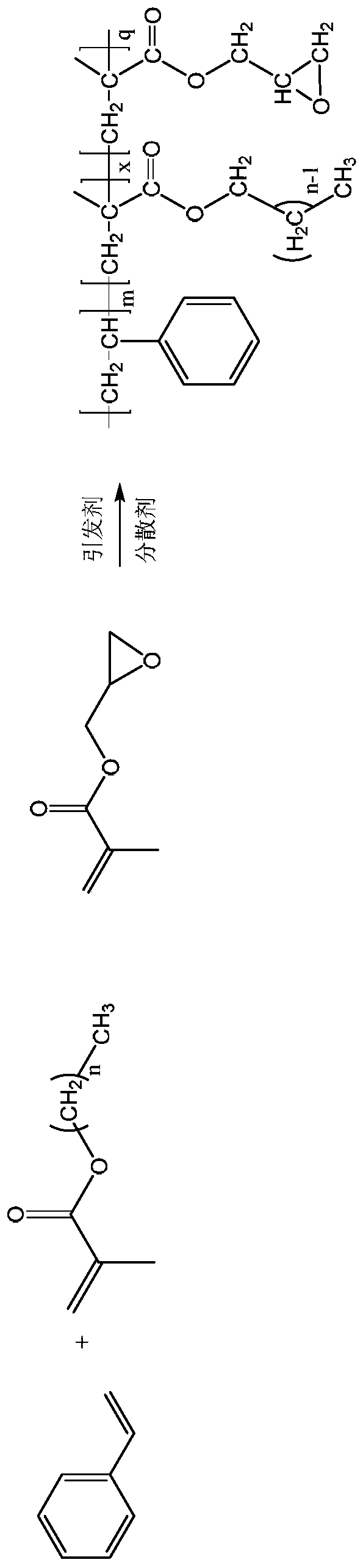

[0044] Such as figure 1 Shown, the preparation method of described compatibilizer comprises the steps:

[0045] (A1), 20 parts of aromatic vinyl monomers, 6 parts of long alkyl methacrylate monomers and 6 parts of epoxy unsaturated hydrocarbons were uniformly mixed by weight to obtain mixed monomers;

[0046] (A2), add 35 parts of dispersant-water solution to the mixed monomer obtained in step (A1), then add 0.2 parts of initiator under continuous stirring conditions, heat up to 78 ° C for 7 hours, then centrifuge, wash and dry, Get compatibilizer.

Embodiment 2

[0057] A toughened PA / ABS alloy material, comprising the following raw materials in parts by weight:

[0058]

[0059] The compatibilizer is an epoxy-type compatibilizer with a long side chain structure.

[0060] The polyamide is prepared by mixing PA66 and PA11 in a weight ratio of 1:1.

[0061] The rubber content of the ABS high rubber powder is 50 wt%, and the acrylonitrile content of the ABS high rubber powder is 20 wt%.

[0062] The preparation method of described compatibilizer comprises the steps:

[0063] (A1), by weight, 10 parts of aromatic vinyl monomers, 2 parts of long alkyl methacrylate monomers and 2 parts of epoxy unsaturated hydrocarbons are uniformly mixed to obtain mixed monomers;

[0064] (A2), add 30 parts of dispersant-water solution to the mixed monomer obtained in step (A1), then add 0.1 part of initiator under continuous stirring conditions, raise the temperature to 70 ° C for 6 hours, then centrifuge, wash and dry, Get compatibilizer.

[0065] ...

Embodiment 3

[0075] A toughened PA / ABS alloy material, comprising the following raw materials in parts by weight:

[0076]

[0077] The compatibilizer is an epoxy-type compatibilizer with a long side chain structure.

[0078] The polyamide is prepared by mixing PA46 and PA7 at a weight ratio of 1:1.

[0079] The rubber content of the ABS high rubber powder is 70 wt%, and the acrylonitrile content of the ABS high rubber powder is 35 wt%.

[0080] The preparation method of described compatibilizer comprises the steps:

[0081] (A1), uniformly mix 30 parts of aromatic vinyl monomers, 10 parts of long alkyl methacrylate monomers and 10 parts of epoxy unsaturated hydrocarbons in parts by weight to obtain mixed monomers;

[0082] (A2), add 40 parts of dispersant-water solution to the mixed monomer obtained in step (A1), then add 0.3 parts of initiator under continuous stirring conditions, heat up to 85 ° C for 8 hours, then centrifuge, wash and dry, Get compatibilizer.

[0083] The aromatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com