A kind of method for preparing sodium sulfide by reduction of molten state of industrial sodium sulfate

A sodium sulfate, molten state technology, applied in the field of sodium sulfide preparation, can solve the problems of small equipment corrosion, equipment corrosion, complex process, etc., and achieve the effects of low environmental pollution, low equipment corrosion, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

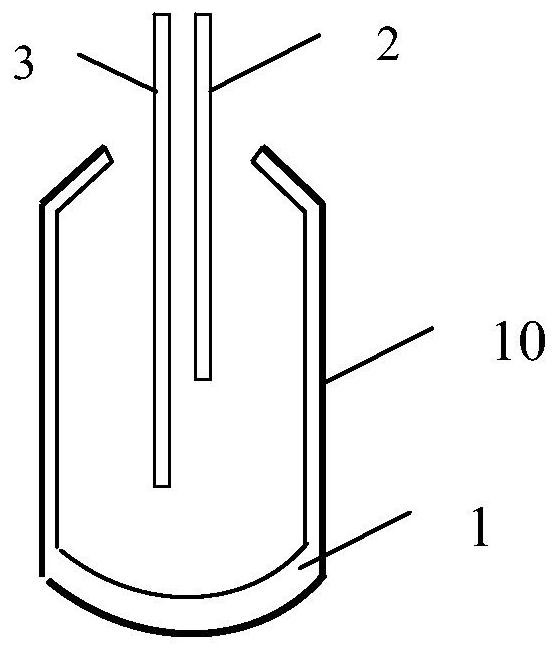

Image

Examples

Embodiment 1

[0047] (1) adopting fractional crystallization to purify industrial sodium sulfate to a purity of 90%;

[0048](2) Put the purified industrial sodium sulfate as a raw material into the blowing furnace, ignite and heat it to 1000°C with a gas heating gun, turn the industrial sodium sulfate raw material into molten sodium sulfate, and then use a gas spray gun to spray coke oven gas to carry out blowing reduction, reducing molten sodium sulfate to molten sodium sulfide;

[0049] (3) Molten state sodium sulfide is poured out from blowing furnace, casts molding on iron plate, obtains sodium sulfide after cooling;

[0050] (4) The waste gas produced in blowing reduction is injected into the lye absorption tower for absorption treatment.

Embodiment 2

[0052] (1) industrial sodium sulfate is purified to a purity of 95% by adopting fractional crystallization;

[0053] (2) Put the purified industrial sodium sulfate as a raw material into the blowing furnace, ignite and heat it to 1050°C with a gas heating gun, turn the industrial sodium sulfate raw material into molten sodium sulfate, and then blow natural gas with a gas spray gun for blowing Reduction, reducing molten sodium sulfate to molten sodium sulfide;

[0054] (3) Molten state sodium sulfide is poured out from blowing furnace, casts molding on iron plate, obtains sodium sulfide after cooling;

[0055] (4) The waste gas produced in blowing reduction is injected into the lye absorption tower for absorption treatment.

Embodiment 3

[0057] (1) industrial sodium sulfate is purified to a purity of 93% by fractional crystallization;

[0058] (2) Put the purified industrial sodium sulfate as a raw material into the blowing furnace, ignite and heat it to 1100°C with a gas heating gun, turn the industrial sodium sulfate raw material into molten sodium sulfate, and then use a gas spray gun to blow blast furnace gas to blow Refining reduction, reducing molten sodium sulfate to molten sodium sulfide;

[0059] (3) Molten state sodium sulfide is poured out from blowing furnace, casts molding on iron plate, obtains sodium sulfide after cooling;

[0060] (4) The waste gas produced in blowing reduction is injected into the lye absorption tower for absorption treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com