Telescopic spool pay-off pin device

An I-shaped wheel and wire pin technology is applied in the field of the I-shaped wheel pay-off pin device, which can solve the problems affecting the production efficiency of the steel cord, shorten the service life of the pay-off pin, and the low pass rate of the steel cord twisting, etc. The effect of eliminating tension instability, eliminating speed changes and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

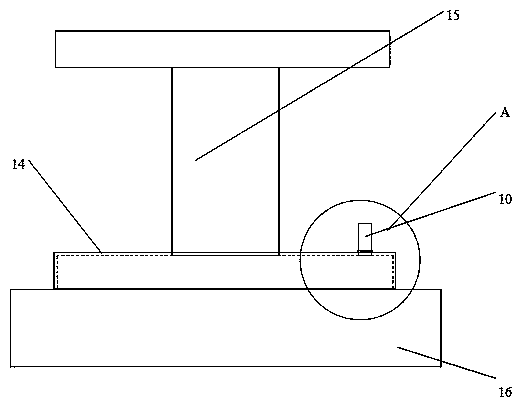

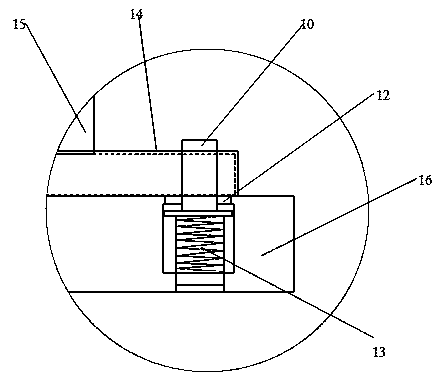

[0015] The characteristics, working principle and advantages of the telescopic I-wheel pay-off pin device of the present invention are described in detail as follows in conjunction with the accompanying drawings:

[0016] refer to figure 1 Shown is a schematic structural view of a retractable I-shaped wheel pay-off pin device according to an embodiment of the present invention. The pay-off pin device includes a pay-off seat 16 and a pay-off pin 10, and the pay-off pin 10 is arranged on the pay-off seat 16 , there is a pin hole (not marked) on the flange surface of the I-shaped wheel 15, and the set-off pin 10 is used to place and fasten the I-shaped wheel 15. The set-off pin 10 is correspondingly inserted in the pin hole, and the set-off pin 10 It is a combined upper and lower cylinder structure, the pay-off pin 10 is set in the stepped hole (not marked) of the pay-off seat 16, and the stepped hole 16 is provided with a circlip 12, and the diameter of the upper half of the pay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com