A flexible material cutting supply device and granulation system

A technology of flexible materials and supply devices, applied in metal processing, etc., can solve the problems of difficult transportation and clamping, and expand the height of the clamping part, so as to avoid concentrated accumulation, facilitate debonding, and solve the problems of difficult transportation and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

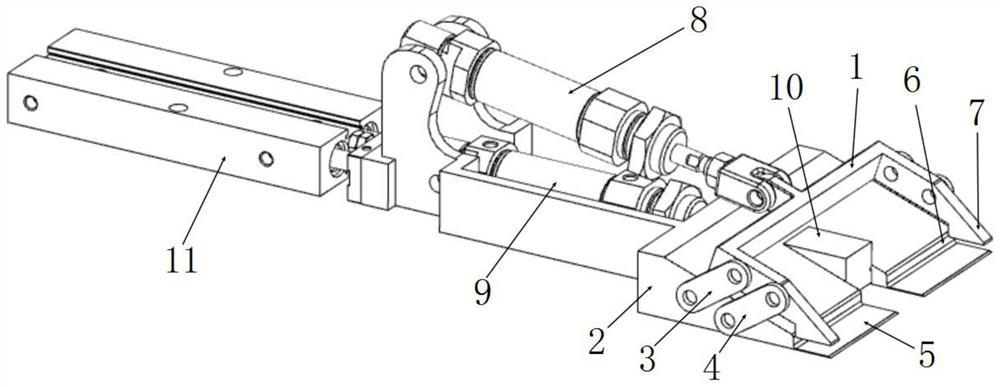

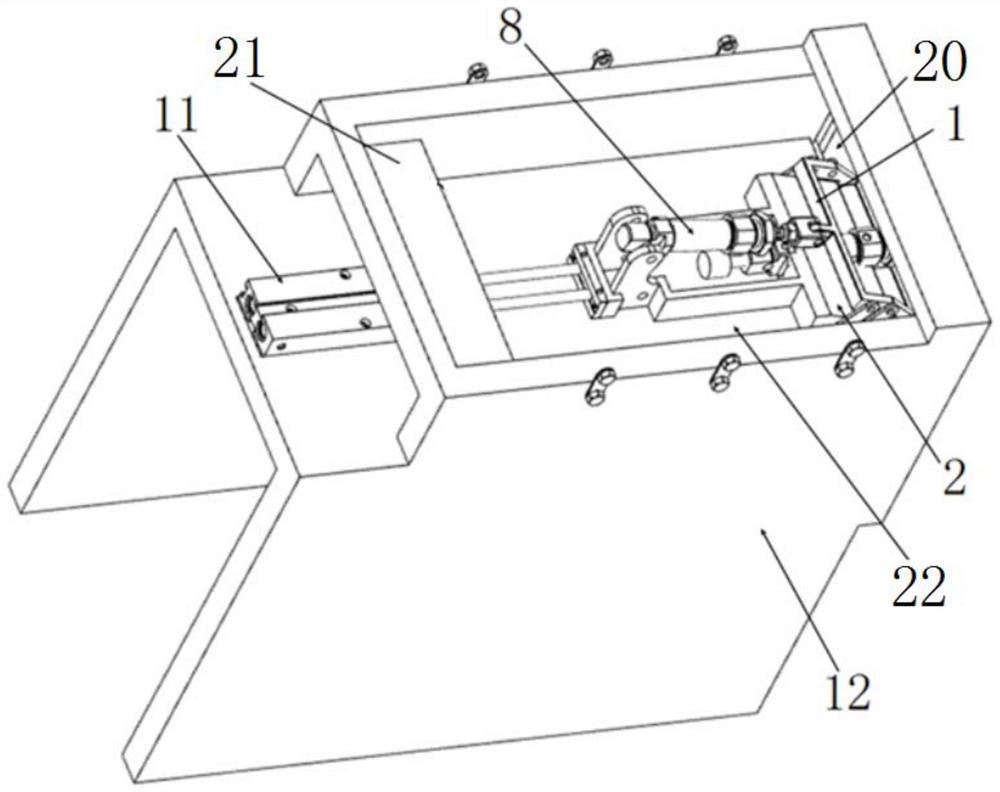

[0033] In a typical implementation of the present application, such as Figure 1-Figure 2 As shown, a supply conveyor capable of storing flexible materials to be cut is proposed.

[0034] combine figure 1As shown, it includes a box body 21. The box body is a cuboid structure with a cavity 22 inside. The left end of the cavity is provided with an opening. The opening 20 communicates with the cavity and the outside, and the opening passes through a baffle Covering and closing, the baffle can slide up and down at the opening. When it slides to the top, it just completely closes the cavity of the box body. When it slides to the bottom, it just does not block the opening at all, which is convenient for the components in the cavity. And the material is discharged from the opening; a clamp and a push-pull mechanism 11 are installed in the cavity, and the push-pull mechanism is installed at the end of the cavity away from the opening. Under the condition of moving through the openin...

Embodiment 2

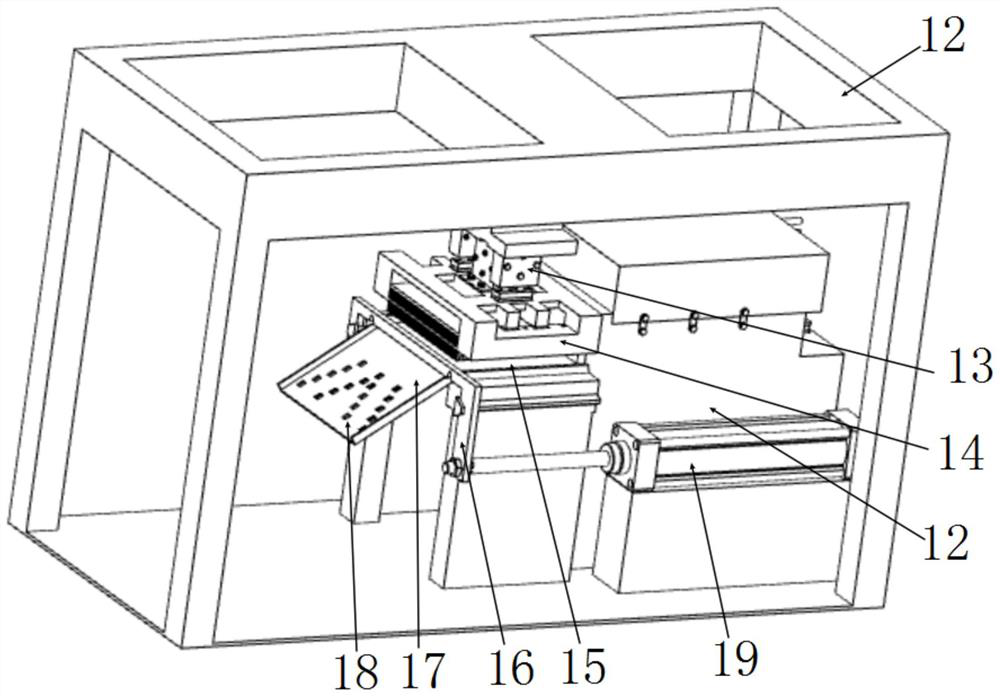

[0049] The application also provides a flexible material granulation system, such as image 3 Shown, and utilized the cutting supply device described in embodiment 1.

[0050] It includes a cutting supply device, a granulation mechanism and a discharge mechanism. The granulation mechanism includes a drive mechanism 13, a cutter 14 and a carrier plate 15 arranged in sequence from top to bottom. The drive mechanism drives the cutter to reciprocate up and down, thereby changing the cutter The distance between the bearing plate and the bearing plate is used to cut the materials on the bearing plate; the flexible material cutting supply device is arranged on the end of the bearing plate away from the discharge plate, and the clamp is used to transport the material under the drive of the push-pull mechanism Between the carrying plate and the cutter, the discharge mechanism includes a scraper 16 reciprocatingly sliding along the carrying plate and a discharge plate 17 installed at on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com