Cnt assembled film modified steel wire array electrode, preparation method and application thereof

A technology of array electrodes and steel wires, applied in the field of electrochemical testing, can solve problems such as unavoidable construction joints, debonding of steel wires and epoxy resin layers, etc., to improve debonding, improve sensitivity and long-term performance, and ensure system integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

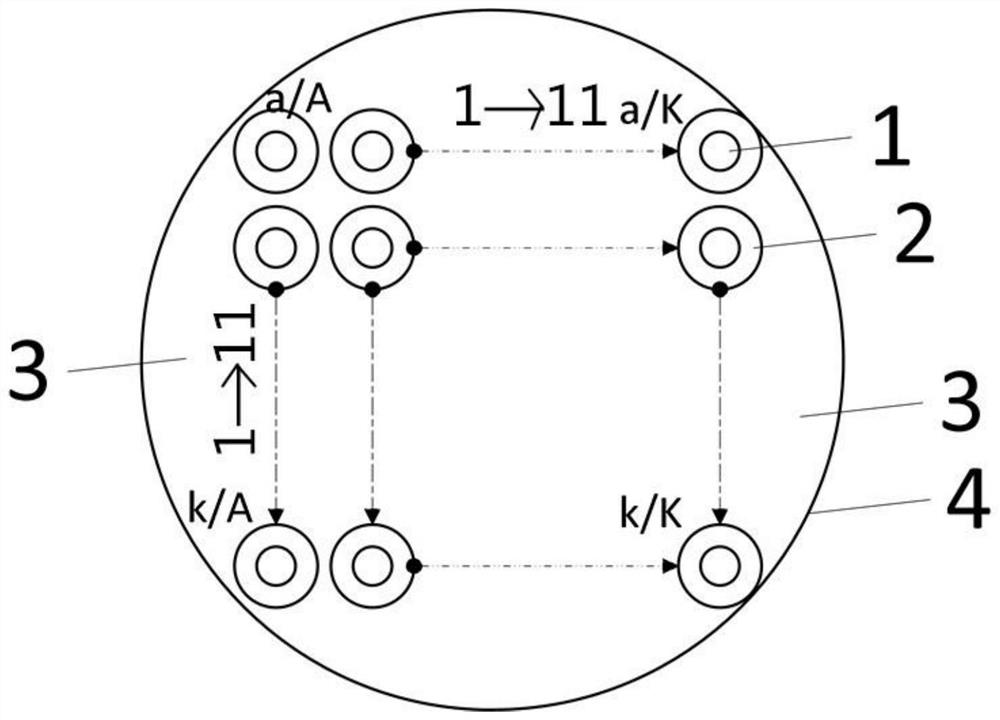

[0065] In order to better understand the CNT assembled thin film modified steel wire array electrode of the present invention, the present invention also provides a preparation method of a CNT assembled thin film modified steel wire array electrode, comprising the following steps:

[0066] (1) A plurality of steel wires 1 are subjected to a certain treatment process, so that the surface of the steel wire 1 is negatively charged to modify the effect, and a negatively charged modified steel wire 1 is obtained;

[0067] (2) Using the LBL alternate assembly process, the surface layer of the negatively charged modified steel wire 1 obtained in step (1) is assembled with a multi-layer CNT film 2 to prepare a CNT assembled film modified steel wire 1;

[0068] (3) Weld one end of the CNT assembled film modified steel wire 1 obtained in step (2) to one end of the wire, and use an insulating heat-shrinkable tube to insulate and wrap the welded part to form a modified electrode wire;

[...

Embodiment 1

[0075] A method for preparing a CNT assembled thin film modified steel wire array electrode provided by the invention;

[0076] The steel wire used is Q235D, and the CNT assembly film is a 2-layer double-walled CNT film.

[0077] Include the following steps:

[0078] like figure 1 As shown, in the first step, 121 steel wires with a diameter of 1.5 mm and a length of 50 mm are used in an ozone treatment process (treatment in a closed environment for 24 hours) to achieve a negatively charged modification effect on the surface of the metal wire;

[0079] In the second step, the LBL alternate assembly process (10min positively charged electrolyte ~ 3min deionized water rinsing ~ 15min air drying ~ 20min negatively charged CNT) was assembled on the surface of 121 negatively charged modified steel wires with 2 layers of CNT double walls. Film, made of CNT assembly film modified steel wire;

[0080] The third step is to weld one end of 121 CNT-assembled film-modified steel wires t...

Embodiment 2

[0086] The steel wire used in the preparation method in this embodiment is Q335B, and the CNT assembly film is a 6-layer double-walled CNT film. Other steps of the method are the same as those in Embodiment 1, and will not be repeated here.

[0087] performance testing

[0088] After the epoxy resin is solidified, the surface layer of resin is polished off, and the electrochemical workstation is used to sequentially test after soaking in simulated seawater (3.5% NaCl solution) containing concrete corrosion solution for 2h, 1d, 3d, 7d, 21d, 30d, and 60d respectively. The current between each electrode wire and the remaining 120 electrode wires coupled together, it is found that the corresponding current distribution diagram also begins to appear anodic current peak after 7 days; and as the soaking time prolongs, its peak value increases significantly, At 60d, its maximum anode current reaches 12.38μA.cm -2, indicating that after the Q335B steel was soaked in simulated seawater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com