Bending device for step plate and use method thereof

The technology of a bending device and a tread plate is applied in the field of auxiliary devices of industrial construction engineering, which can solve the problems of difficulty in reaching acceptance standards, increase labor costs, and increase the cost of auxiliary materials, meet the requirements of ensuring appearance quality and accuracy, and improve labor efficiency. , the effect of eliminating the process of cutting and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

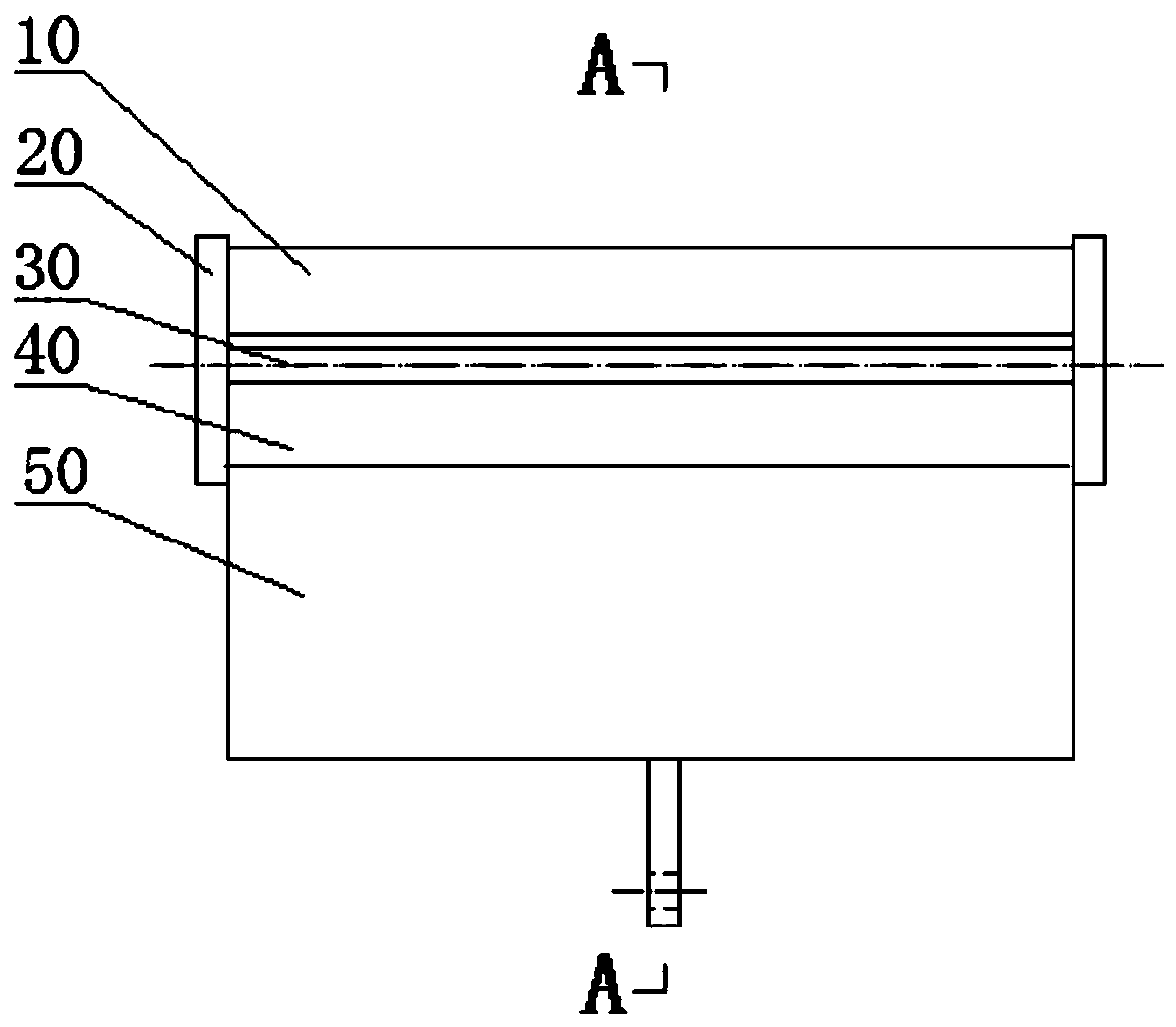

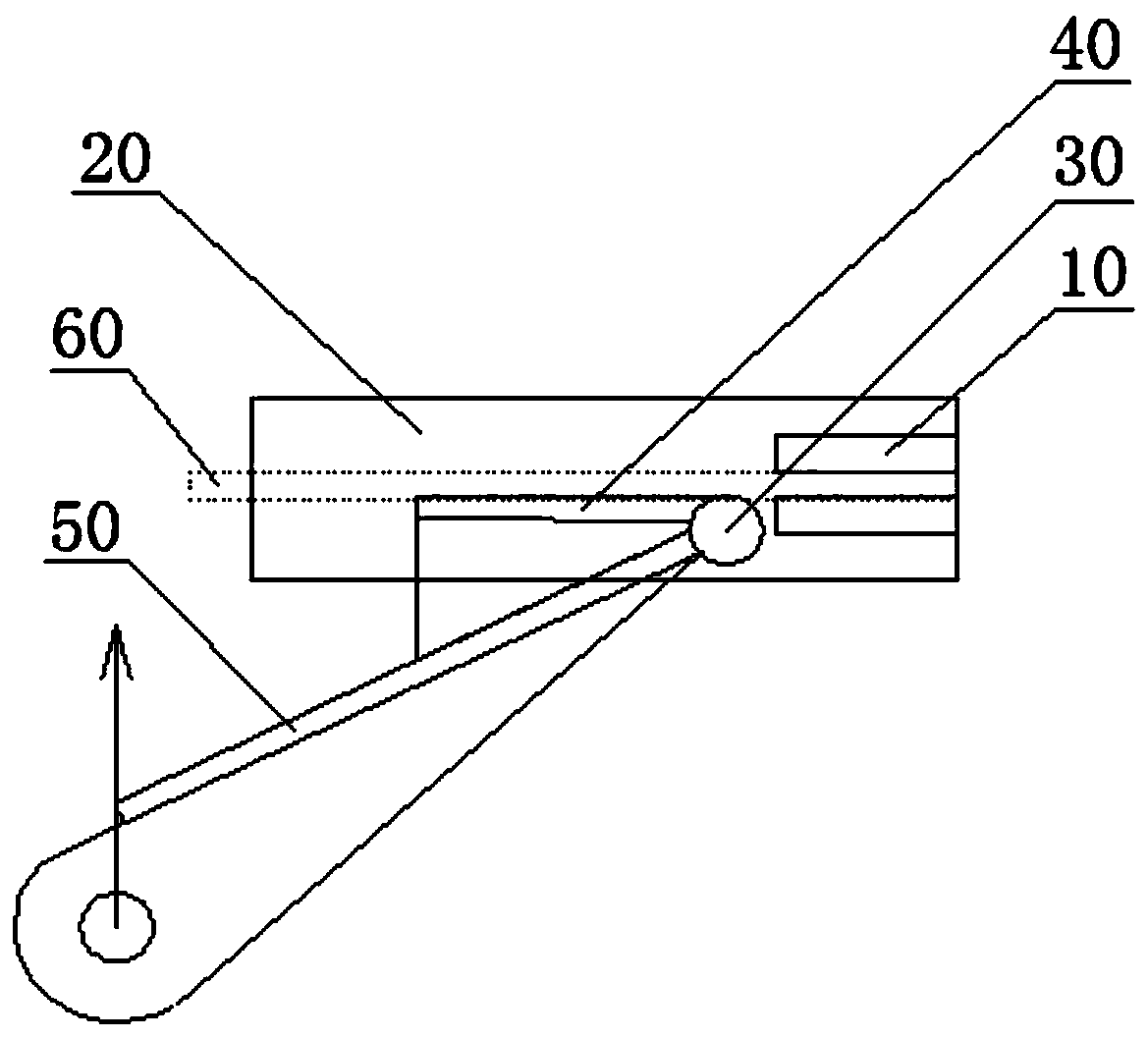

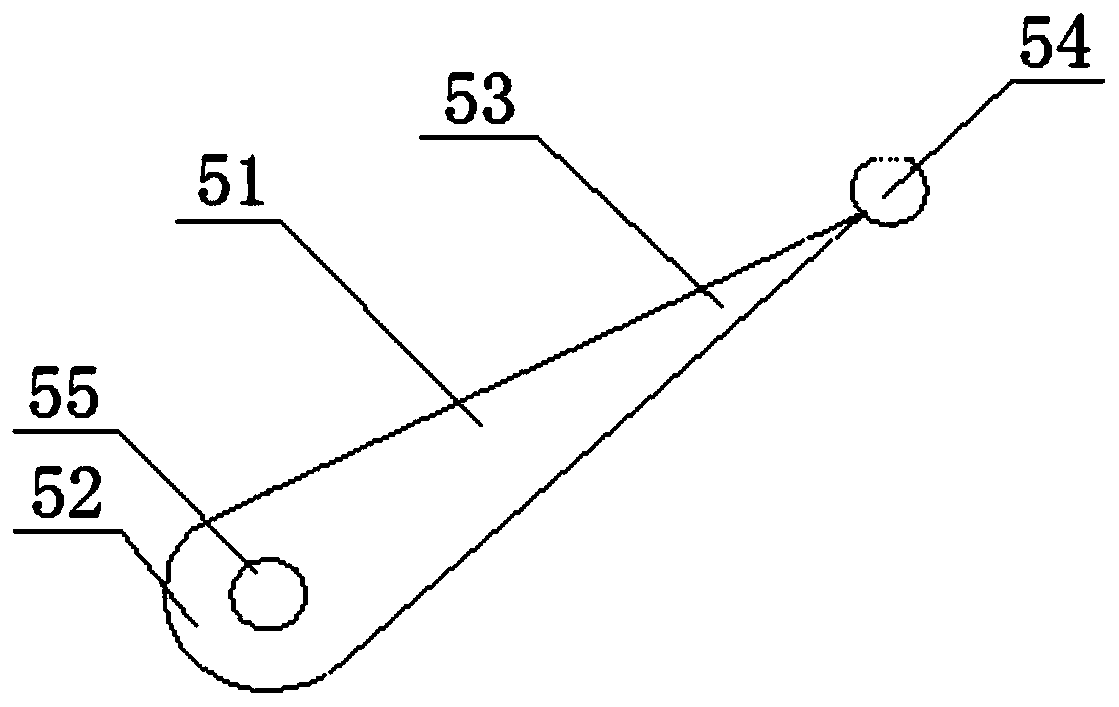

[0037] One embodiment of the present invention is a bending device for tread plates, such as Figure 1-3 As shown, including clamping part 10, fixed part 20, rotating part 30 and reinforcing part 50, clamping part 10 is arranged symmetrically, and there is a gap channel between clamping parts 10; at both ends of clamping part 10 The fixed part 20 is arranged symmetrically; the rotating part 30 is set through the reinforcement part 50, the fixed part 20 and the clamping part 10 in sequence; the step board 60 is placed in the gap channel and fits with the inner wall structure of the gap channel.

[0038] Specifically, the clamping portion 10 is a steel plate, and the longitudinal depth of the clamping portion 10 is determined according to the length of the tread plate 60 that needs to be bent. Generally, the longitudinal depth of the clamping portion 10 is 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com