Efficient steel bar bending equipment

A steel bar bending and bending technology, applied in the field of high-efficiency steel bar bending equipment, can solve problems such as low bending efficiency, and achieve the effect of fast bending and guaranteed fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

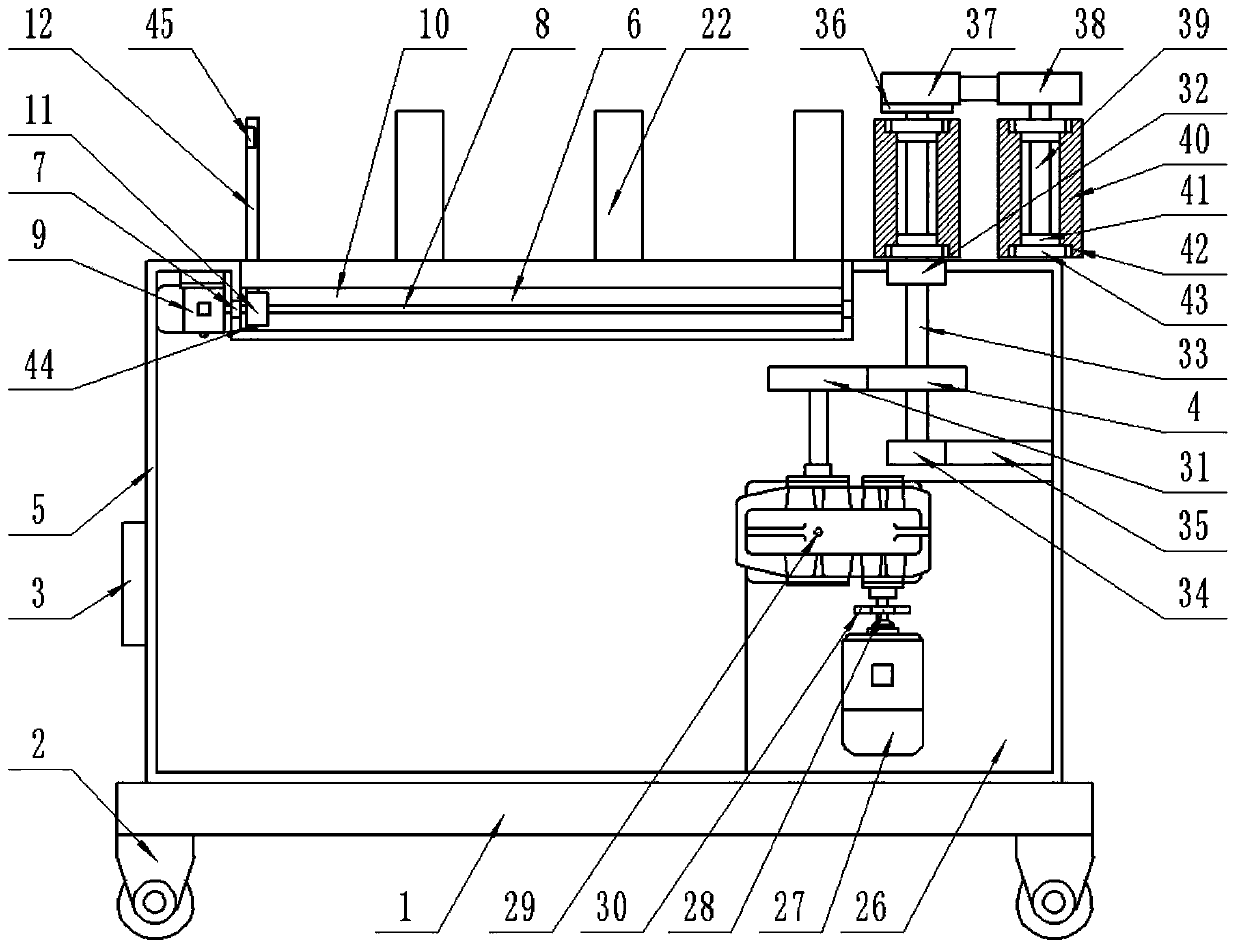

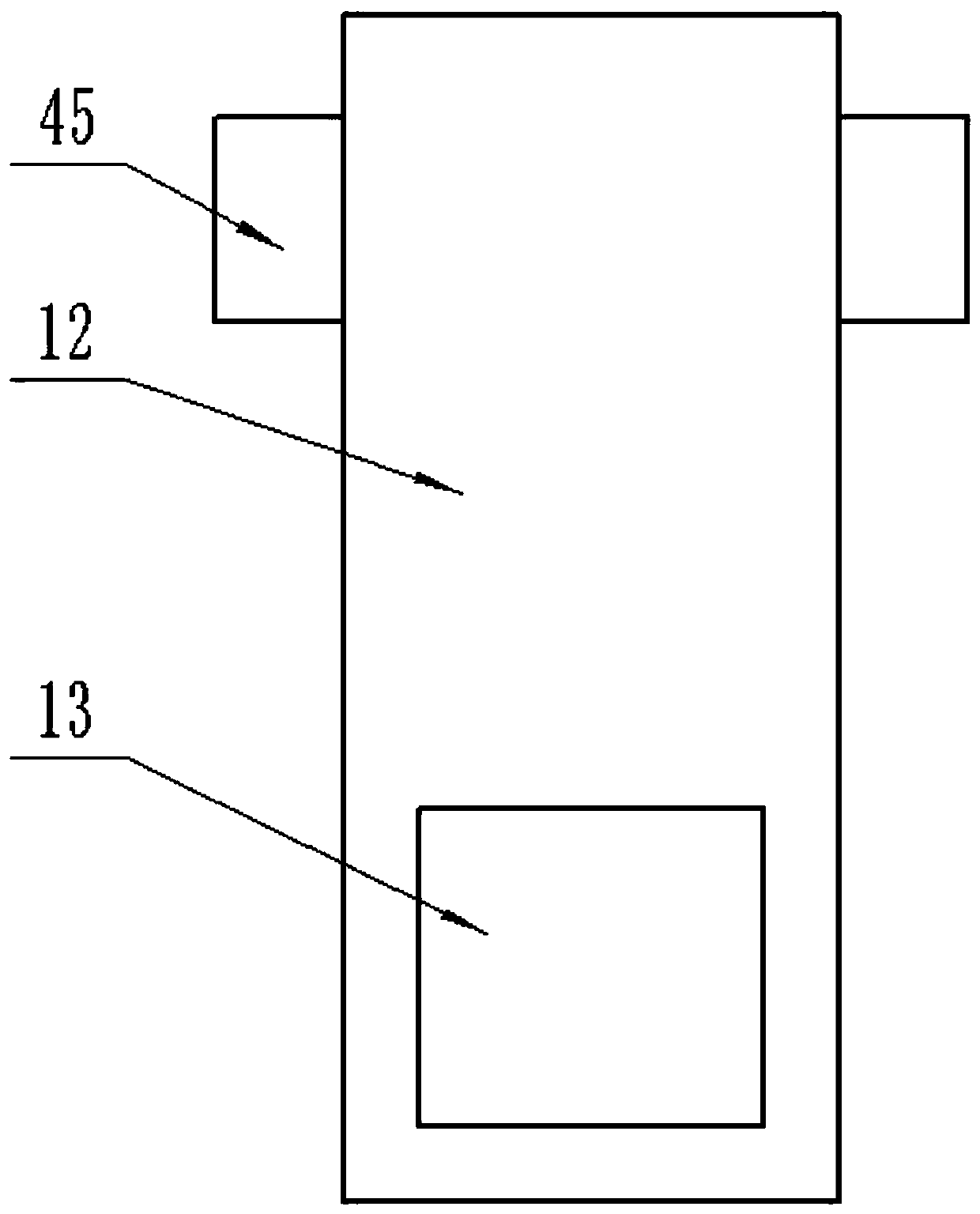

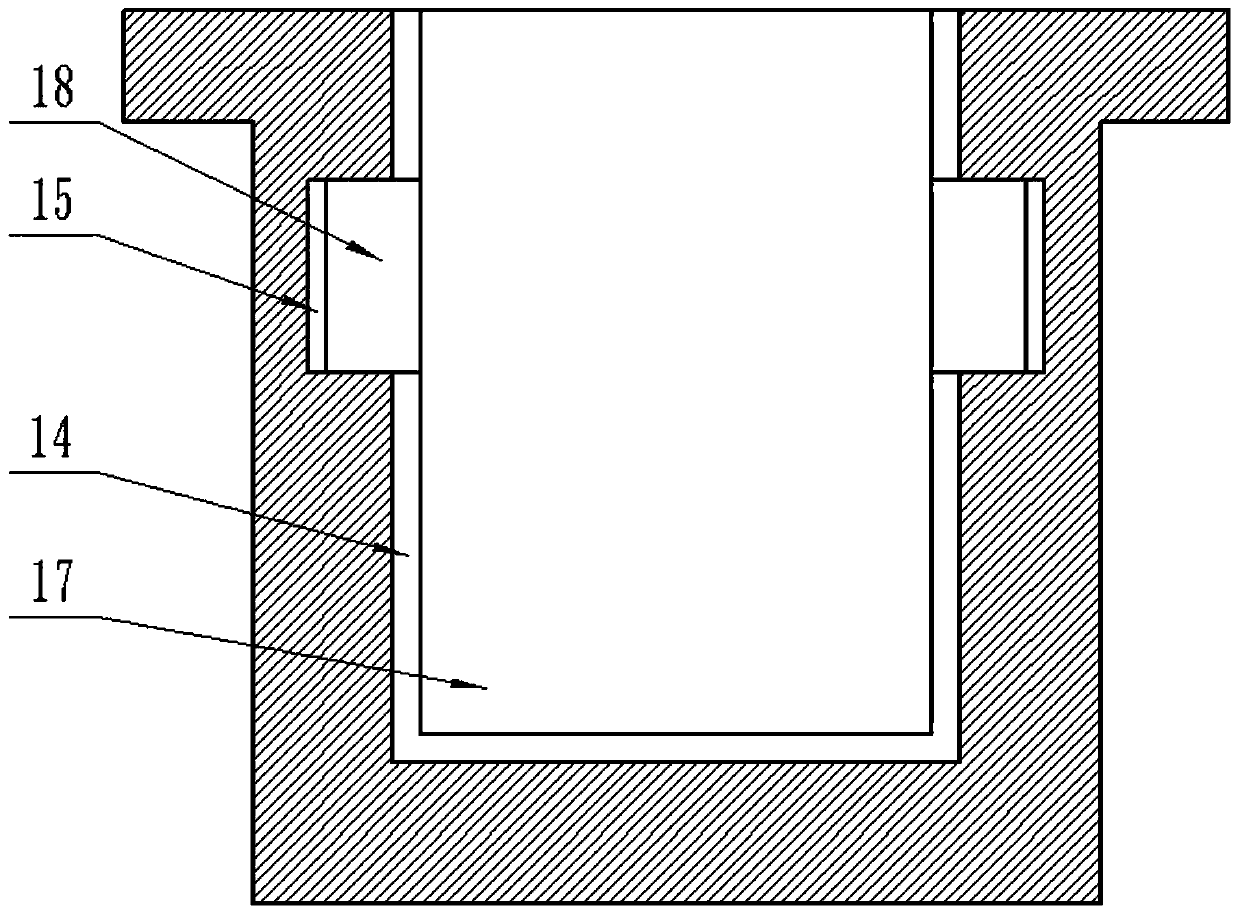

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, in this implementation:

[0024] In this device, the device is powered by connecting with an external power supply, and the external power supply is electrically connected with the controller 3, drive motor one 9, electric telescopic rod one 16, electric telescopic rod two 25, drive motor two 27, and hydraulic cylinder 37 For power supply, the model of the controller 3 is the PLC controller of the FX3U-32MR / ES-A model, the control signal output terminal of the controller 3 is connected with the drive motor one 9, the electric telescopic rod one 16, the electric telescopic rod two 25, and the drive motor 227. The hydraulic oil cylinder 37 is electrically connected, and the signal receiving end of the controller 3 is electrically connected with the infrared ranging sensor 44 and the displacement sensor 45, thereby controlling the operation of the device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com