Apparatus and method for synthesizing 2-methoxy-3,4-dihydropyran

A dihydropyran and methoxy technology, applied in the chemical industry, can solve problems such as blockage, affecting the health of employees and surrounding personnel, and achieve the effect of uniform temperature rise and improved production yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

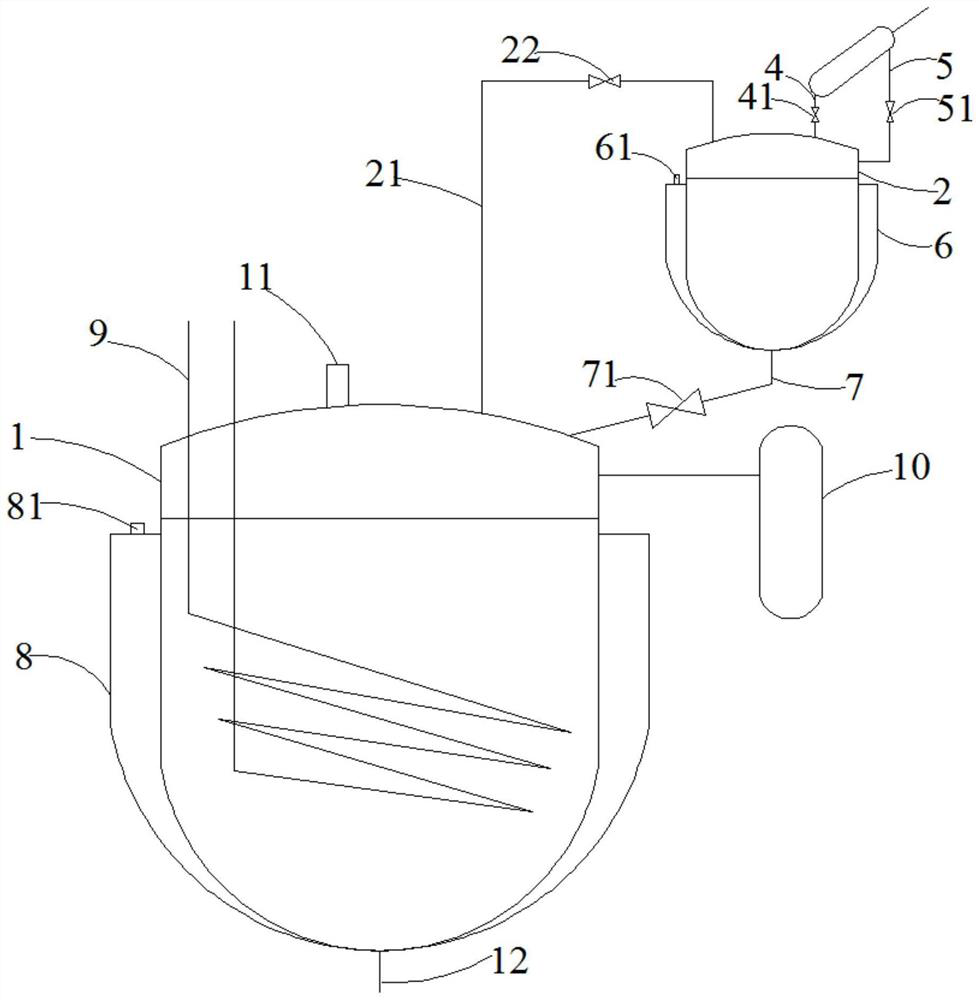

[0037] A method for synthesizing 2-methoxy-3,4-dihydropyran, comprising the following steps:

[0038] S1. Put 1.5 tons of acrolein, 1.5 tons of vinyl methyl ether and 3 kg of inhibitor hydroquinone into the reaction kettle through the feeding pipe, open the gas storage tank, and feed nitrogen into the reaction kettle to make the reaction The pressure in the kettle is 1Mpa;

[0039] S2. Pass steam into the second jacket through the steam inlet, and at the same time, pass cooling water with a temperature of 8°C through the water inlet to the water inlet pipe at the right time, so that the temperature in the reactor will rise to 160°C within 9 hours and keep for 2 hours. ;

[0040]S3, then open the first valve on the connecting pipe, the unreacted acrolein and vinyl methyl ether gas in the reactor enter the recovery tank, and at the same time, pass the low-temperature liquid into the first jacket through the liquid inlet, such as Liquid nitrogen, etc., the temperature in the re...

Embodiment 2

[0042] A method for synthesizing 2-methoxy-3,4-dihydropyran, comprising the following steps:

[0043] S1. Add 1 ton of acrolein, 1 ton of vinyl methyl ether and 1 kg of polymerization inhibitor phenothiazine into the reactor through the feed pipe, open the gas storage tank, and feed nitrogen into the reactor to make the reactor The pressure inside is 3Mpa;

[0044] S2. Pass steam into the second jacket through the steam inlet, and at the same time, pass cooling water at a temperature of 5°C through the water inlet to the water inlet pipe at the right time, so that the temperature in the reaction kettle is raised to 120°C within 9 hours and kept for 2 hours. ;

[0045] S3, then open the first valve on the connecting pipe, the unreacted acrolein and vinyl methyl ether gas in the reactor enter the recovery tank, and at the same time, pass the low-temperature liquid into the first jacket through the liquid inlet, such as Liquid nitrogen, etc., the temperature in the recovery tan...

Embodiment 3

[0047] A method for synthesizing 2-methoxy-3,4-dihydropyran, comprising the following steps:

[0048] S1. Put 2 tons of acrolein, 2 tons of vinyl methyl ether and 4 kg of polymerization inhibitor p-methoxyphenol into the reaction kettle through the feed pipe, open the gas storage tank, and feed nitrogen into the reaction kettle to The pressure in the reactor is 5Mpa;

[0049] S2. Pass steam into the second jacket through the steam inlet, and at the same time, pass cooling water with a temperature of 8°C through the water inlet to the water inlet pipe at the right time, so that the temperature in the reaction kettle is raised to 100°C within 9 hours and kept for 2 hours. ;

[0050] S3, then open the first valve on the connecting pipe, the unreacted acrolein and vinyl methyl ether gas in the reactor enter the recovery tank, and at the same time, pass the low-temperature liquid into the first jacket through the liquid inlet, such as Liquid nitrogen, etc., the temperature in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com