Sesame paste and preparation method thereof

A technology of sesame paste and white sesame, which is applied in the direction of food preservation, food ingredients as antioxidants, food ingredients as antimicrobial preservation, etc., can solve problems such as inconvenient eating, easy stratification and hardening, and reduce the flavor and taste of sesame paste. Achieve the effect of reducing loss and waste and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

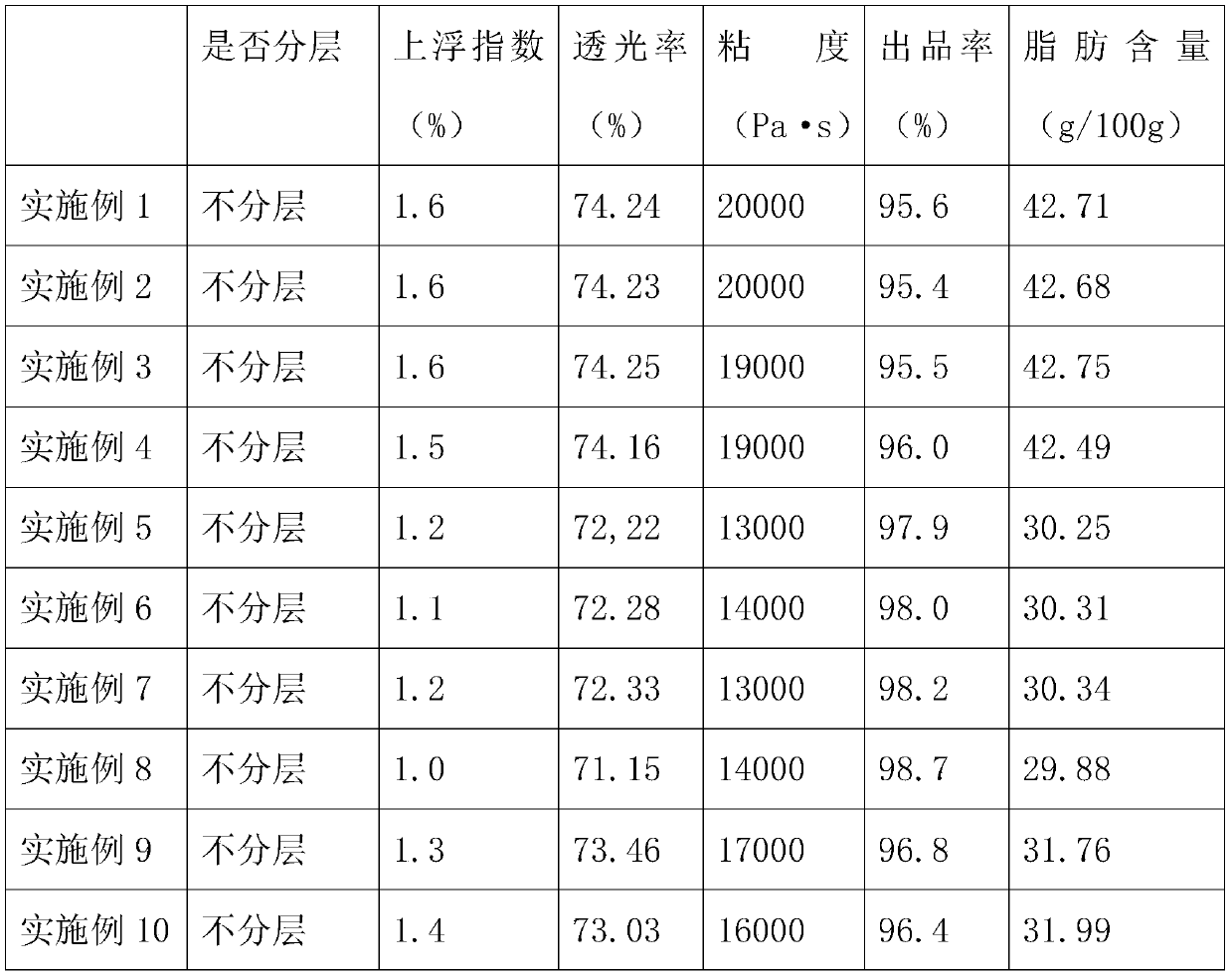

Embodiment 1

[0068] A sesame paste comprising the following components:

[0069] White sesame 40kg; fennel powder 2kg; sesame oil 4kg; edible salt 2kg; polyanionic cellulose 2kg; curdlan 1kg; water 20kg.

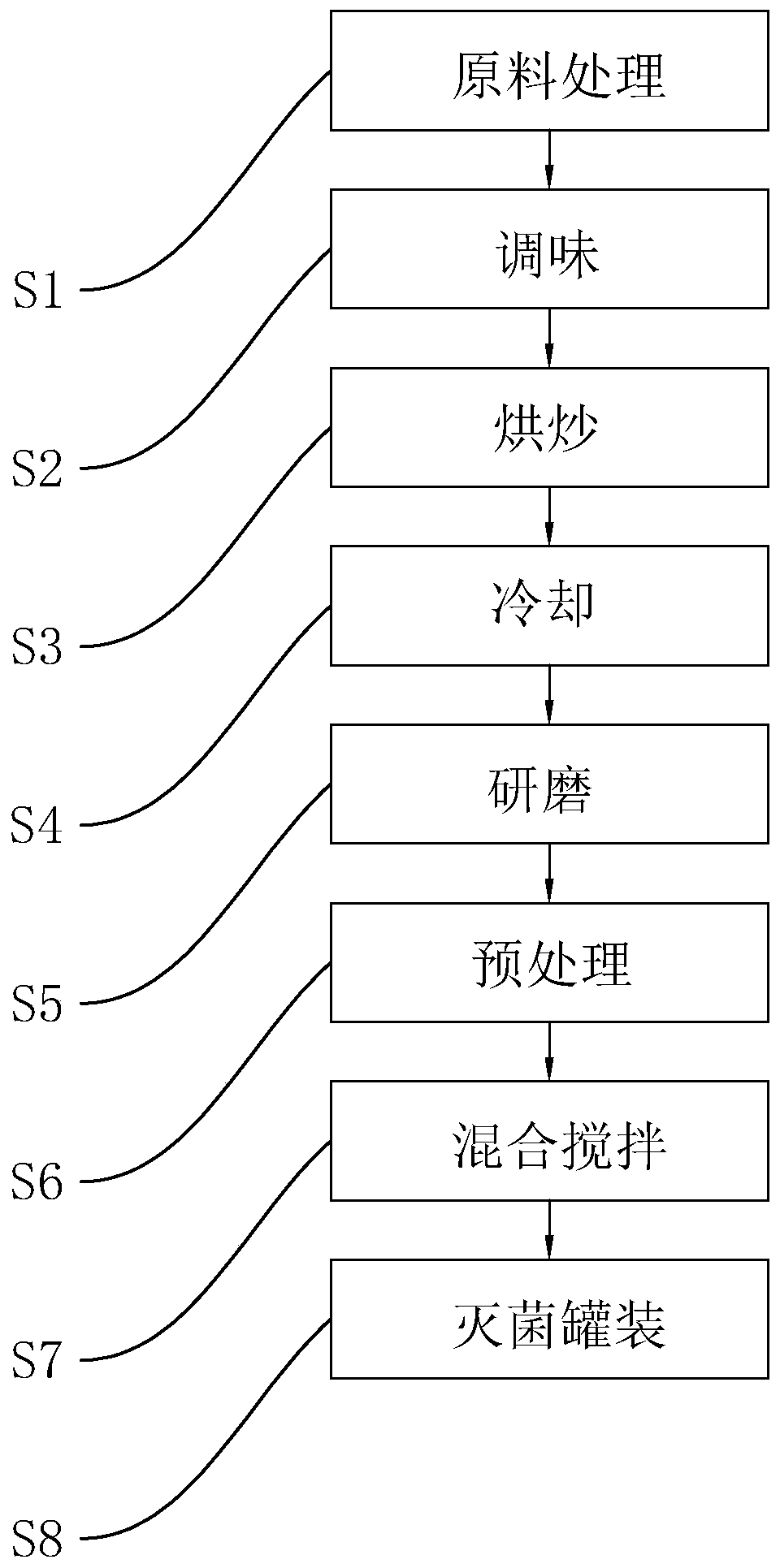

[0070] The preparation method of sesame paste is as follows:

[0071] S1. Raw material processing, details are as follows:

[0072] 40kg of white sesame is sieved, so that solid impurities such as forage mixed in the white sesame are separated from the white sesame and left on the sieve, and the sieved white sesame is put into water for elution for 10 minutes, so that the raw material is small in size, Dry white sesame seeds and grass fodder are floating on the water surface. At this time, use tools to fish them out. After fishing out, use tools to stir the white sesame seeds that have settled in the water, so that the washing of white sesame seeds is cleaner. When the water surface When there are no more floating objects on the surface, the white sesame seeds can be fished out and dra...

Embodiment 2

[0088] The difference with embodiment 1 is:

[0089] Tahini includes the following components:

[0090] White sesame 43kg; fennel powder 2.2kg; sesame oil 4.3kg; edible salt 2.1kg; polyanionic cellulose 2.5kg; curdlan 1.2kg; water 21kg.

Embodiment 3

[0092] The difference with embodiment 1 is:

[0093] Tahini includes the following components:

[0094] White sesame 44kg; fennel powder 2.4kg; sesame oil 4.5kg; edible salt 2.2kg; polyanionic cellulose 3kg; curdlan 1.4kg; water 22kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com