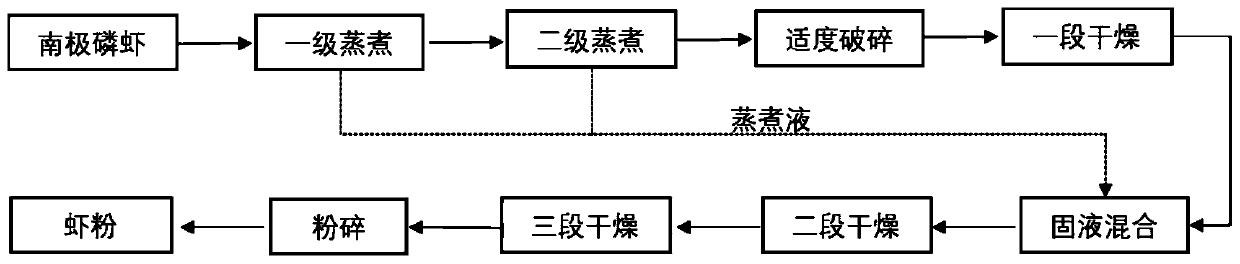

Manufacturing process of euphausia superba powder

An Antarctic krill and production process technology, applied in food forming, food science, application, etc., can solve problems affecting product quality and yield, slow material heating rate, and large loss of active substances, etc., to improve energy utilization. , Guarantee quality, reduce degradation and loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] Compared with the prior art, this method increases the process of crushing and solid-liquid mixing, reduces the process of solid-liquid separation, and at the same time innovates the process of key processes such as cooking and drying. The specific implementation process is described in detail as follows:

[0021] S1. Cooking: The cooking process is divided into two stages: the Antarctic krill is placed in the first-stage heating cylinder, and it is rapidly heated to 50-65°C within 2 minutes, and the heating rate is greater than 25°C / min; the material heated by the first stage enters the second stage The heating cylinder can be heated rapidly to 90-100°C, the heating rate is greater than 30°C / min, the heating time is controlled within 2 minutes, and the entire cooking process is controlled within 4 minutes;

[0022] S2. Crushing: the kri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com