Novel high-load abnormal-shaped PCCP (prestressed concrete cylinder pipe) and manufacturing method

A production method and high-load-bearing technology, which is applied in the direction of pipes, rigid pipes, and pipeline connection arrangements, can solve problems such as the failure of filling materials to increase the bearing capacity of the bottom of the pipeline, the failure of the effective bearing surface to meet the requirements, and the loss of life and property. Achieve the effect of saving raw materials, convenient and fast installation and construction, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

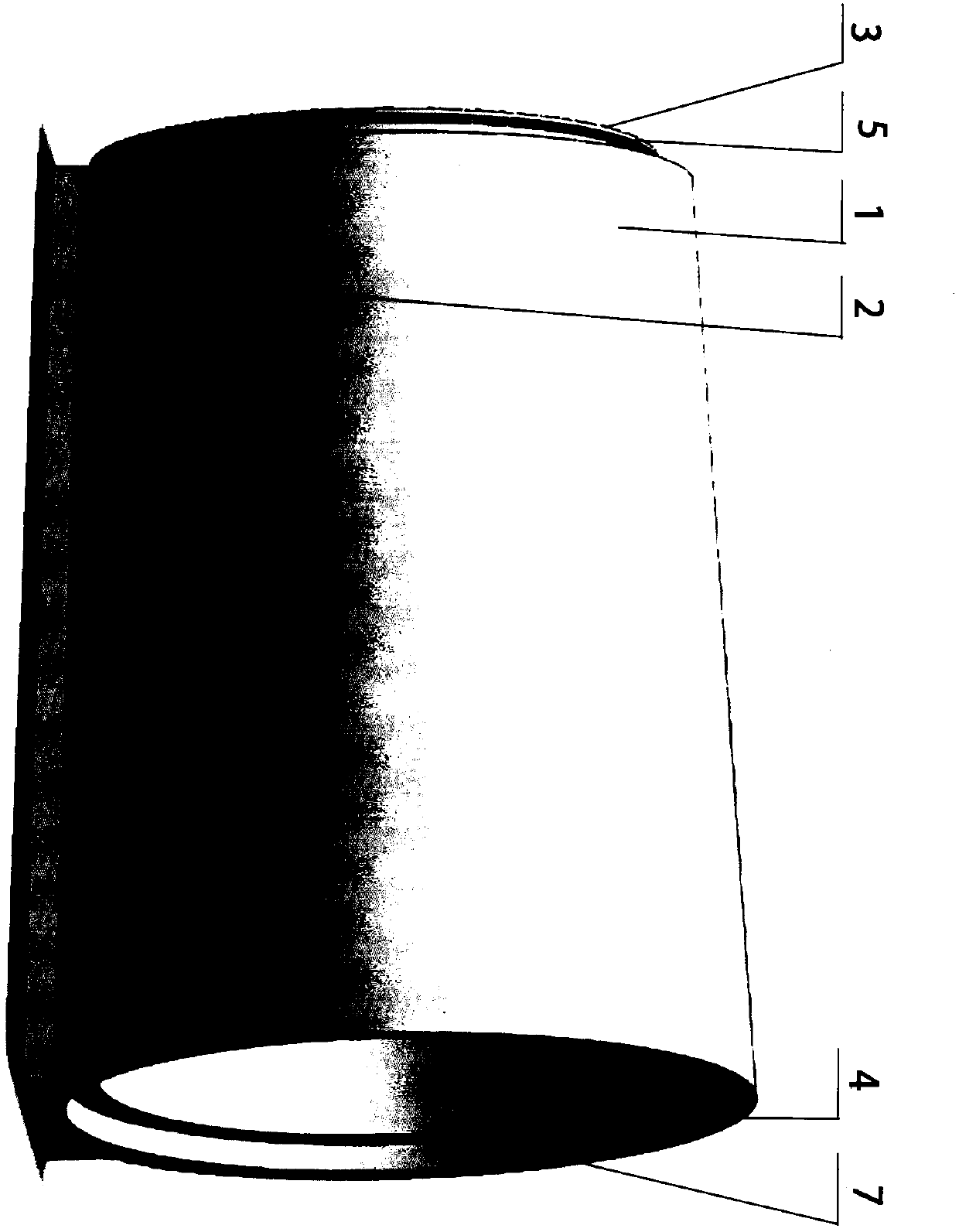

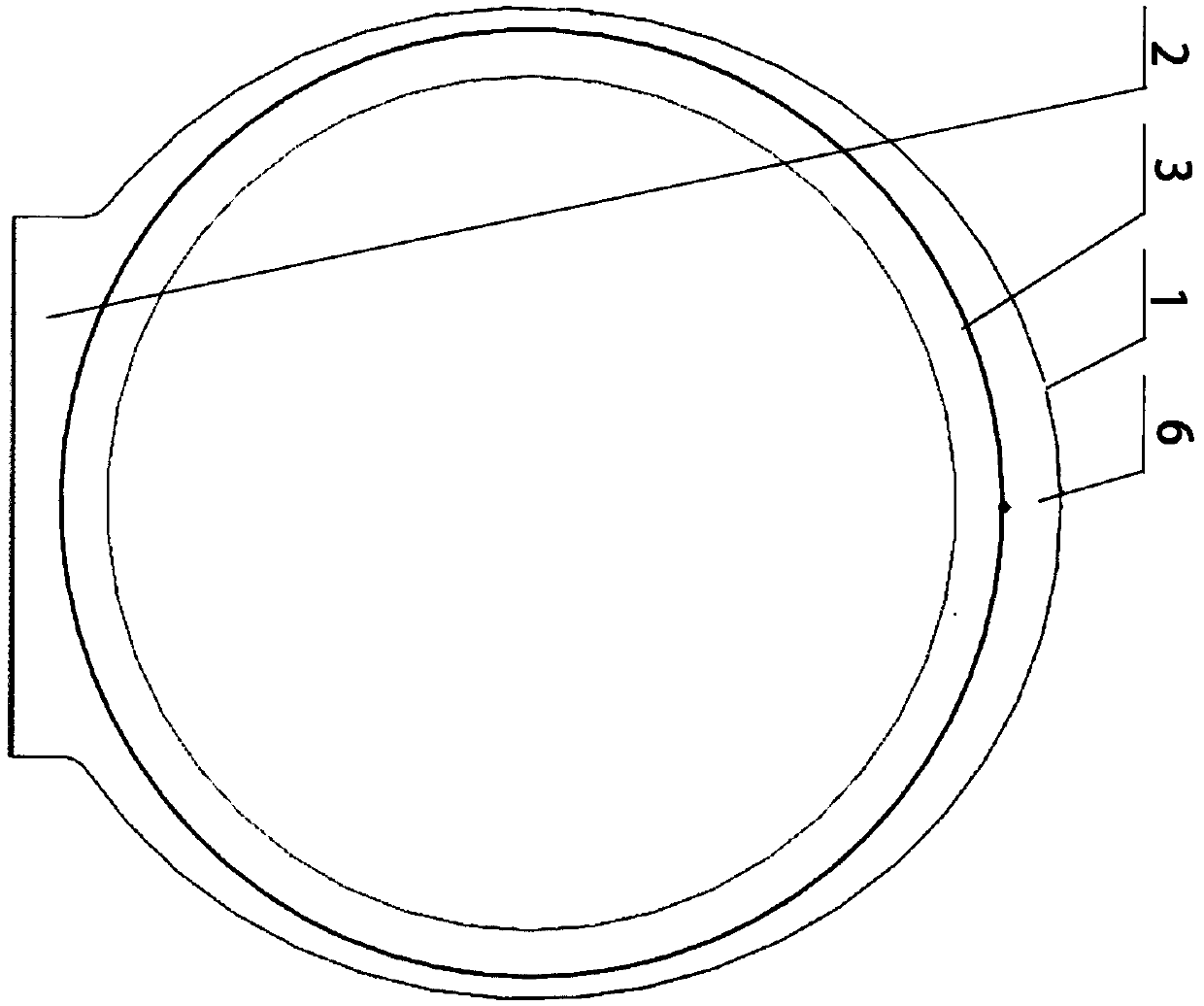

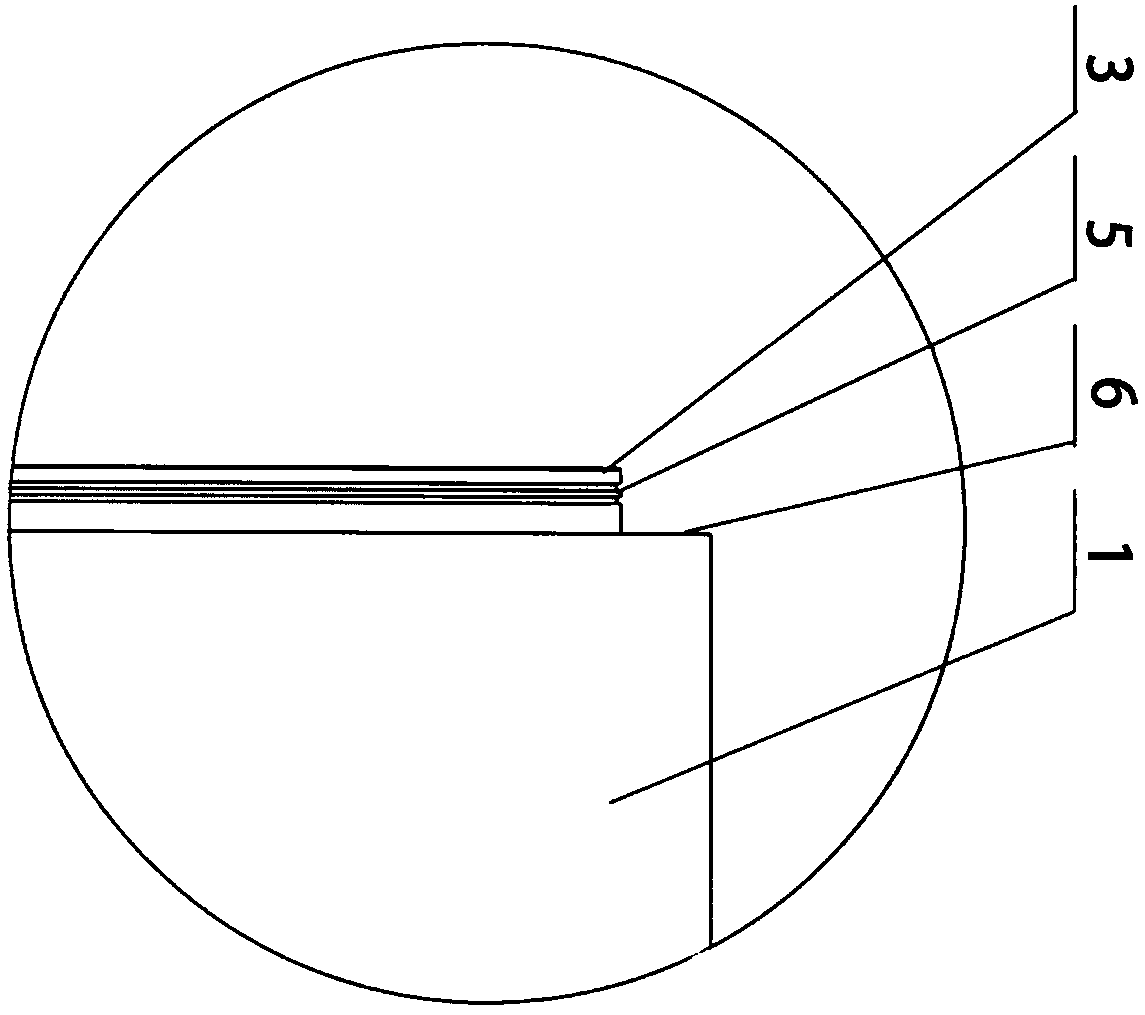

[0024] Show figure 1 figure 2 image 3 Figure 4 Shown is a new type of high-load-bearing special-shaped PCCP pipe and its manufacturing method, which includes a pipe body 1, a pipe bottom widening pressure foot 2, a pipe socket 3, a pipe socket 4, a pipe socket rubber ring groove 5, a socket shoulder 6, a bearing mouth bottom edge. The implementation method is:

[0025] 1. The production of the new high-load-bearing special-shaped PCCP pipe and the production method of the pipe core adopts the traditional prestressed steel cylinder concrete pipe, that is, the PCCP pipe production process, and the pipe socket 3, the pipe socket 4, the pipe socket apron groove 5, The socket shoulder 6 and the bottom edge of the socket are all formed by one-time casting;

[0026] 2. The new type of high-load-bearing special-shaped PCCP pipe and the core of the manufacturing method are wrapped in the outer wall according to the traditional PCCP tube production process, and the outer protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com