A system and method for electric detonation fracturing combined with microwave thermal drive gas drainage

A technology of gas drainage and microwave synergy, which is applied in the direction of gas discharge, mining equipment, mining fluid, etc., can solve the problems of insignificant thermal cracking effect, unsatisfactory gas engineering application effect, and low heat injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

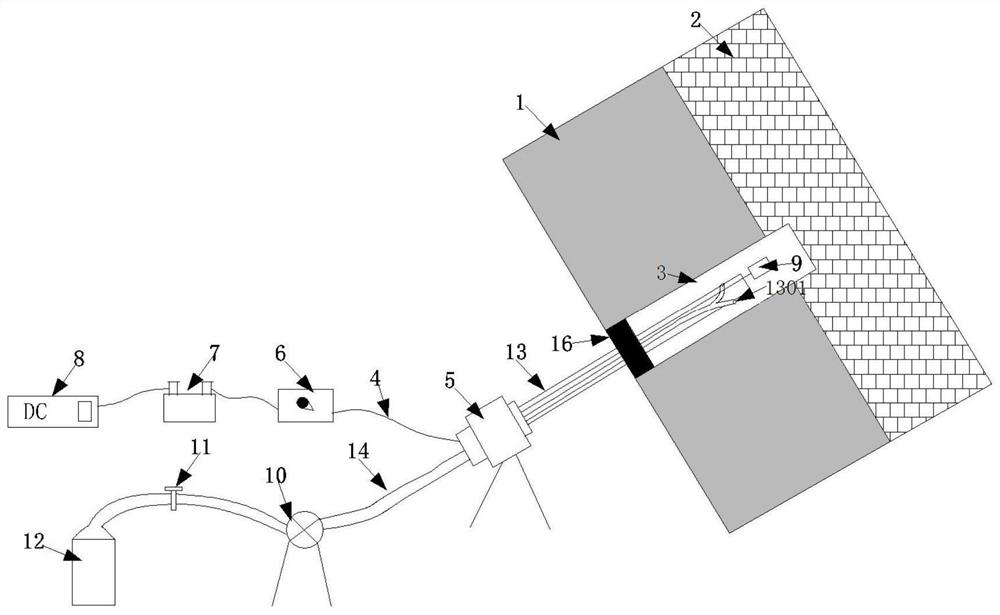

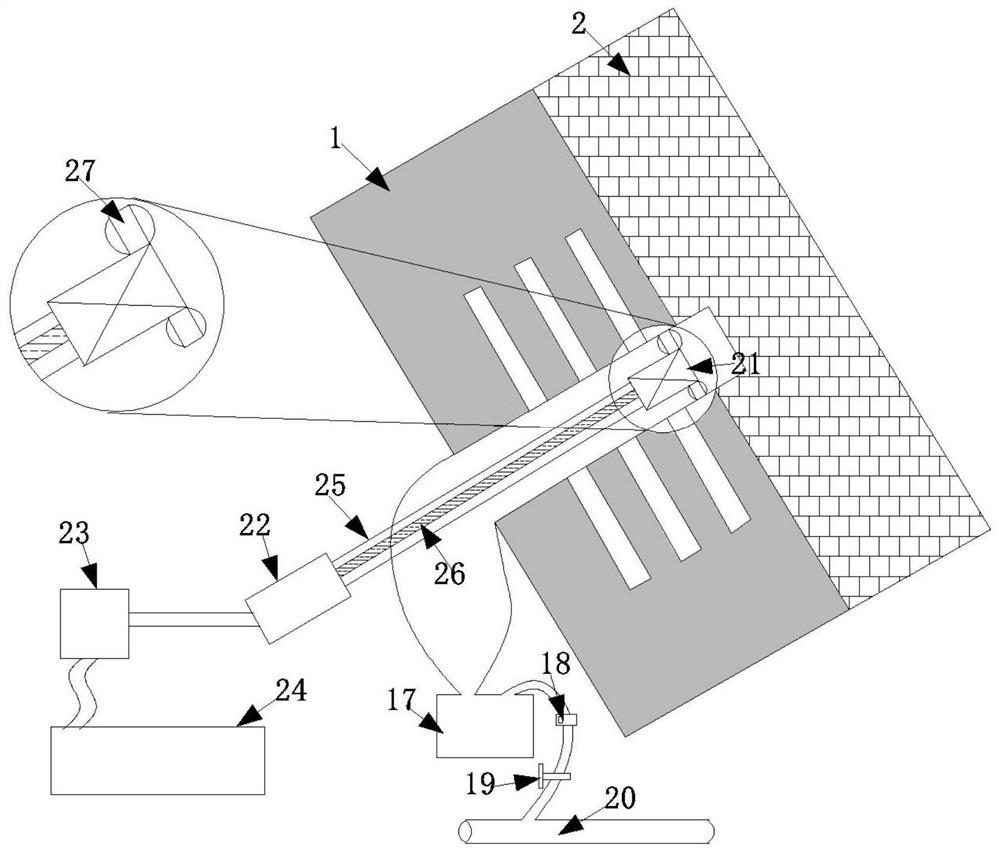

[0041] An electric detonation fracturing cooperative microwave thermal drive gas drainage system is characterized in that it includes a drilling rig 5, an ultra-high pressure water jet generation system, an electric detonation fracturing system, a microwave heat injection system and a gas drainage system.

[0042] The gas extraction system includes an orifice sealer, an air slag separator 17 and a gas extraction pipeline 20 . The orifice sealer is a tubular body. The front end of the orifice sealer is open, and is fixed on the hole wall of the gas extraction hole 3 orifice, and the rear end is connected with the gas slag separator 17 . The gas slag separator 17 is connected to a gas extraction pipeline 20 . A gas concentration detector 18 and a gas extraction pipeline valve 19 are installed on the pipeline between the gas slag separator 17 and the gas extraction pipeline 20 .

[0043] The ultra-high pressure water jet generation system includes an ultra-high pressure water p...

Embodiment 2

[0047] This embodiment discloses a method for using the electric detonation fracturing cooperative microwave thermal drive gas drainage system described in Embodiment 1, including the following steps:

[0048] 1) Construct the gas drainage hole 3 from the side of the road to the coal seam 1. When the gas extraction hole 3 is drilled into the predetermined distance in the coal seam roof 2, stop drilling. Into the nanofluid storage tank 12, the ZnO nanofluid suspension is perfused. Insert the head end of the insulating sleeve 13 into the gas extraction hole 3 . In this embodiment, the good electrical and thermal conductivity of ZnO nanofluid is used to improve the electrical and thermal conductivity of coal, and through the synergistic effect of electric detonation fracturing technology and microwave heating coal injection, efficient fracturing of coal seams and high efficiency of gas are promoted. The realization of desorption effectively improves the effect of gas cracking d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com