Preparation method, product and application of UV-resistant porous fiber with oriented pore structure

A technology of porous fibers and pore structures, which is applied in the field of preparation of ultraviolet-proof porous fibers, can solve the problems of limiting the application of porous fibers, unable to realize continuous large-scale preparation, etc., and achieves the effect of a simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, and dialyze for 24h to prepare a 22.5% silk protein solution.

[0084] Dissolve 0.5 g of chitosan powder in 10 ml of 1% acetic acid solution, stir for 30 min at a speed of 800 rpm / min to make it evenly mixed, and prepare a chitosan solution with a concentration of 50 mg / ml.

[0085] Mix 20ml of silk protein solution and 10ml of chitosan solution evenly, and centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1.

[0086] Mix the ultraviolet shielding agent titanium dioxide nanoparticles with the above mixed solution in a mass ratio of 100:1 between silk protein and titanium dioxide.

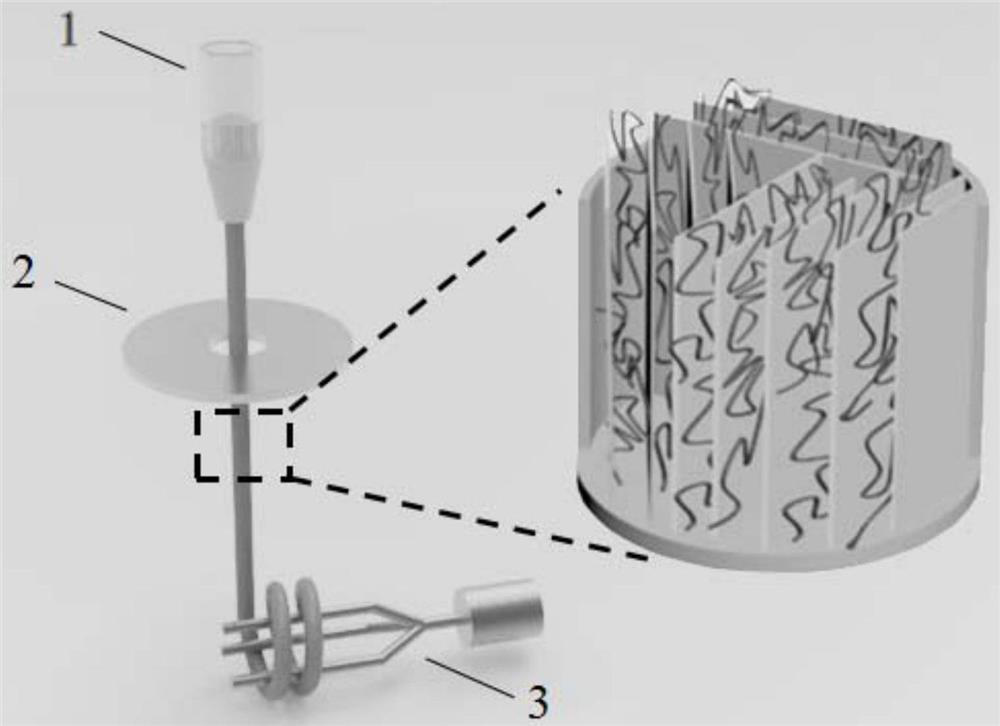

[0087] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low-temperature reaction bath (-100°C), and pass the solution t...

Embodiment 2

[0094](1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, and dialyze for 24h to prepare a 22.5% silk protein solution.

[0095] Dissolve 0.5 g of chitosan powder in 10 ml of 1% acetic acid solution, stir for 30 min at a speed of 800 rpm / min to make it evenly mixed, and prepare a chitosan solution with a concentration of 50 mg / ml.

[0096] After mixing 20ml of silk protein solution and 10ml of chitosan solution evenly, centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein and chitosan is 9:1.

[0097] Mix the ultraviolet shielding agent zinc oxide nanoparticles with the above mixed solution at a mass ratio of 200:1 between silk protein and zinc oxide.

[0098] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low temperature reaction bath (-30, -60, -90°C respectively), and pass...

Embodiment 3

[0103] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, and dialyze for 24h to prepare a 22.5% silk protein solution.

[0104] Dissolve 0.5 g of chitosan powder in 10 ml of 1% acetic acid solution, stir for 30 min at a speed of 800 rpm / min to make it evenly mixed, and prepare a chitosan solution with a concentration of 50 mg / ml.

[0105] After mixing 20ml of silk protein solution and 10ml of chitosan solution evenly, centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1.

[0106] Mix the ultraviolet shielding agent organic nickel polymer with the above mixed solution at a mass ratio of 300:1 between silk protein and organic nickel polymer.

[0107] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low-temperature reaction bath (the temperature is -100°C), p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com