A kind of graphene/silicon dioxide/natural rubber composite material and its preparation method and application

A technology of natural rubber and silica, applied in the field of rubber materials, can solve the problems of easy precipitation, poor dispersion of white carbon black, and poor dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

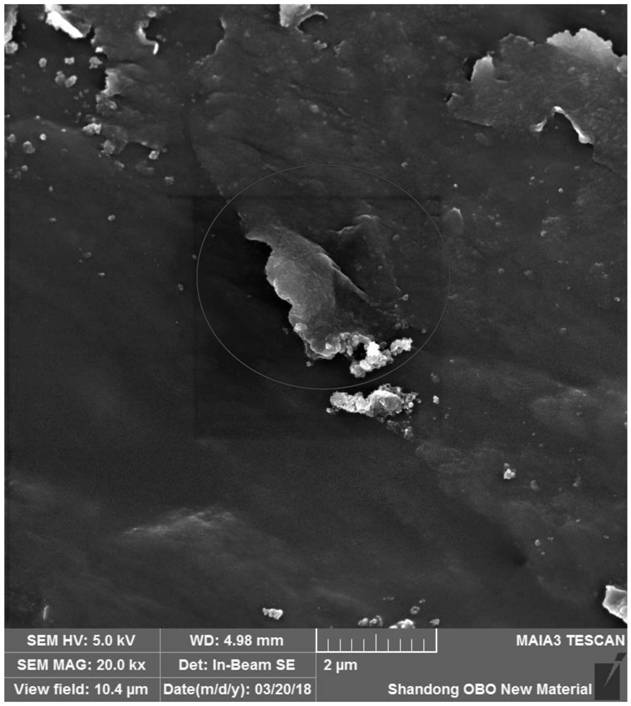

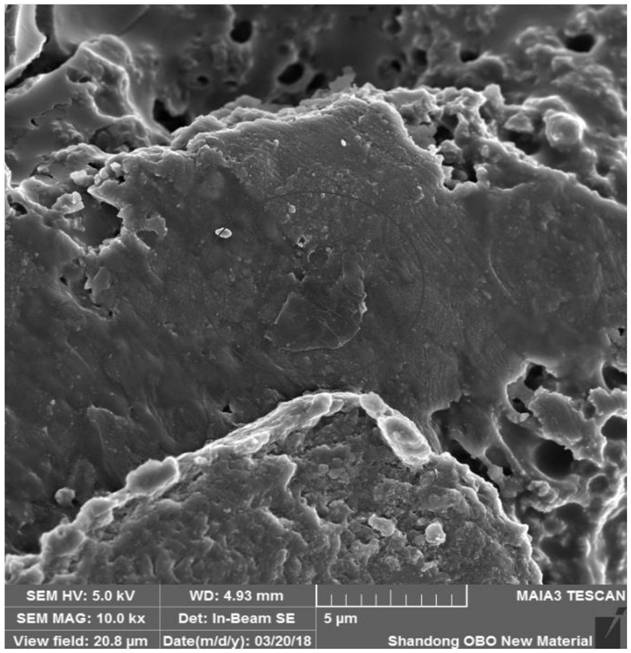

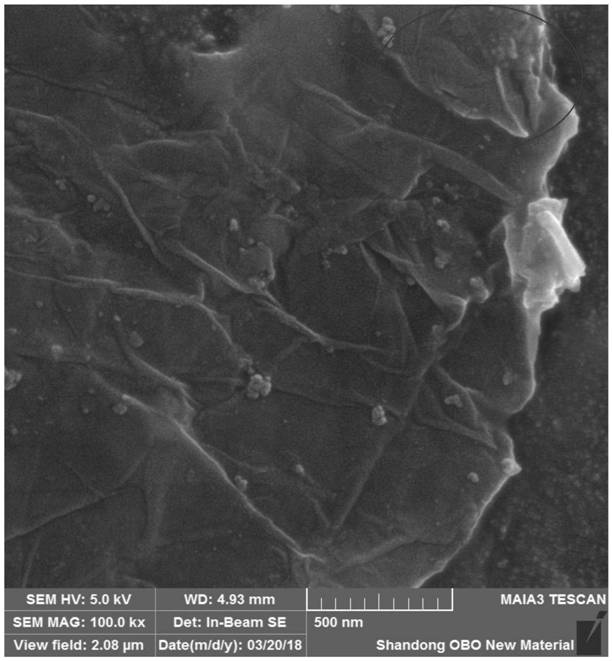

Image

Examples

preparation example Construction

[0063] The present invention also provides a kind of preparation method of graphene / silicon dioxide / natural rubber composite material, comprises the following steps:

[0064] 1) After the graphene oxide aqueous solution and the silica sol are ultrasonically dispersed, a dispersion is obtained;

[0065] 2) After ultrasonically dispersing the dispersion obtained in the above steps and the natural rubber again, a mixed slurry is obtained;

[0066] 3) after reacting the mixed slurry obtained in the above steps and reducing agent, obtain graphene / silica sol / natural rubber composite liquid;

[0067] 4) After the graphene / silica sol / natural rubber composite liquid obtained in the above steps is demulsified, a graphene / silica / natural rubber composite material is obtained.

[0068] The present invention is to the selection, composition and structure of the material in the above-mentioned preparation method, and corresponding optimal principle, and the selection, composition and struct...

Embodiment 1

[0102] Take 10g of graphene oxide, add water to dilute to 3‰, and ultrasonically stir for 1h;

[0103] Add 50 ml of silica sol (40% solid content) dropwise to the graphene oxide slurry at a rate of 10 ml / min, and ultrasonically stir for 1 hour after the addition, to obtain a mixed solution of graphene oxide and silica sol;

[0104] Then the mixed solution of graphene oxide and alkaline silica sol was added dropwise in 150g natural rubber latex with the dropping speed of 15ml / min. Continue ultrasonic stirring for 1 h after the dropwise addition;

[0105] Move the prepared sample to an oil bath, add 10 g of hydrazine hydrate, and react for 24 hours. Add demulsifier dilute sulfuric acid or acetic acid after 24h to demulsify. After breaking the emulsion, it is washed 4 to 6 times by means of suction filtration, and after the washing is completed, it is dried in a vacuum oven to obtain a graphene / silicon dioxide / natural rubber composite material.

[0106] The graphene / silica / nat...

Embodiment 2

[0116] Take 10g of graphene oxide, add water to dilute to 3‰, and ultrasonically stir for 1h;

[0117] Add 100 ml of silica sol (40% solid content) dropwise to the graphene oxide slurry at a dropping rate of 10 ml / min, and ultrasonically stir for 1 h after the addition is complete. Obtain the mixed solution of graphene oxide and silica sol;

[0118] Then the mixed solution of graphene oxide and alkaline silica sol was added dropwise in 150g natural rubber latex with the dropping speed of 15ml / min. Continue ultrasonic stirring for 1 h after the dropwise addition;

[0119]Move the prepared sample to an oil bath, add 10 g of hydrazine hydrate, and react for 24 hours. Add demulsifier dilute sulfuric acid or acetic acid after 24h to demulsify. After breaking the emulsion, it is washed 4 to 6 times by means of suction filtration, and after the washing is completed, it is dried in a vacuum oven to obtain a graphene / silicon dioxide / natural rubber composite material.

[0120] The g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com