3DFF tank structure used for double-layer oil storage tank made by glass fiber reinforced plastics

A technology of glass fiber reinforced plastics and oil storage tanks, applied in underwater structures, infrastructure engineering, containers, etc., can solve the problems of deformation of the outer shell or inner shell, influence on handling and installation, inaccurate leakage detection, etc., and achieve the goal of using Long life, stable structure, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

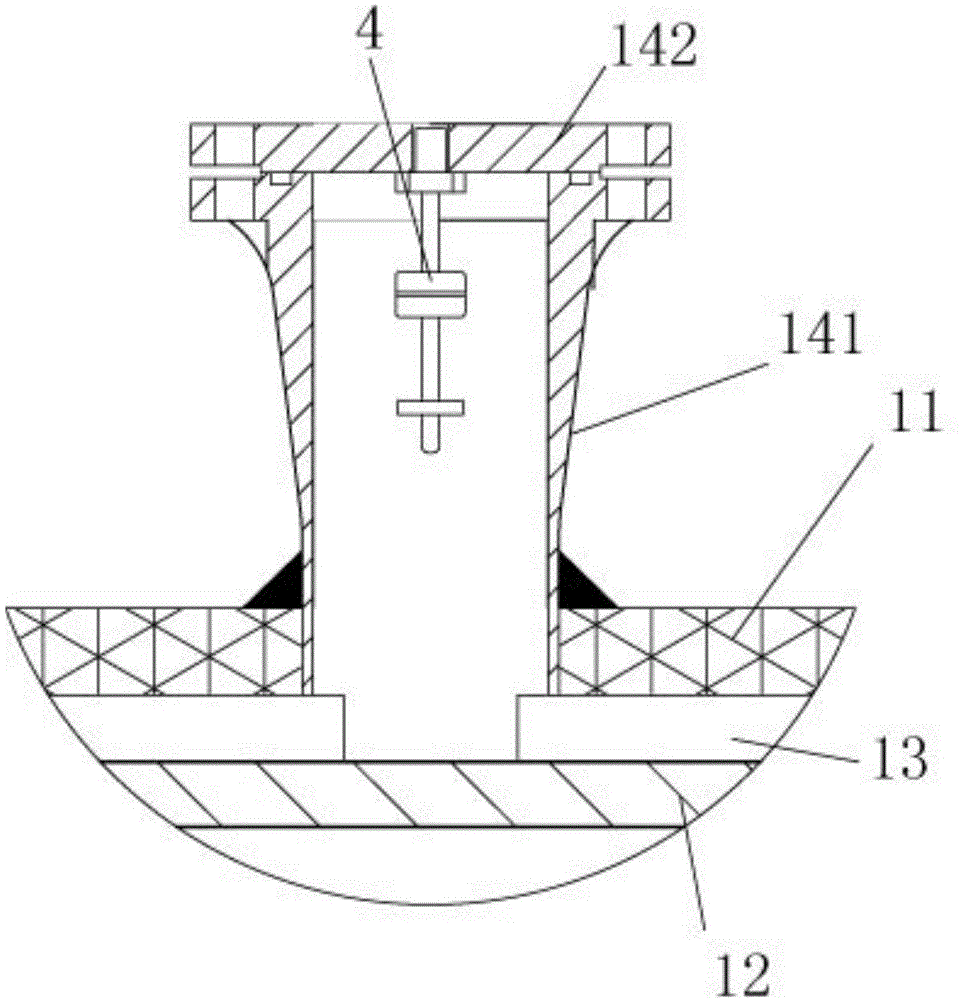

[0021] Examples, see e.g. Figures 1 to 3 As shown, a double-layer FRP oil storage tank 3DFF tank structure includes a tank body 1, the tank body 1 includes an outer shell 11 and an inner shell 12, the inner shell 12 is placed in the outer shell 11, and the inner shell 12 A flexible conductive layer 2 is fixed on the inner wall of the inner casing 12, and a reinforcing rib structure is fixed on the inner wall of the inner casing 12. There is a gap cavity between the outer casing 11 and the inner casing 12, and a gap layer 13 is provided in the gap cavity.

[0022] The outer casing 11 has a first through hole 111 and a second through hole 112, and the inner casing 12 has a first manhole 121 and a second manhole 122, and the first manhole 121 and the second manhole 122 extend respectively. Out of the first through hole 111 and the second through hole 112 , a detection tube 14 is connected to the outer casing 11 , and the detection tube 14 communicates with the gap cavity.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com