Phosphogypsum-doped quick-setting and quick-hardening cement matrix, concrete canvas prepared from cement matrix and construction method of concrete canvas

A technology for concrete canvas and fast-hardening cement, which is applied in chemical instruments and methods, textiles and papermaking, film/sheet-like adhesives, etc. Stability qualified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

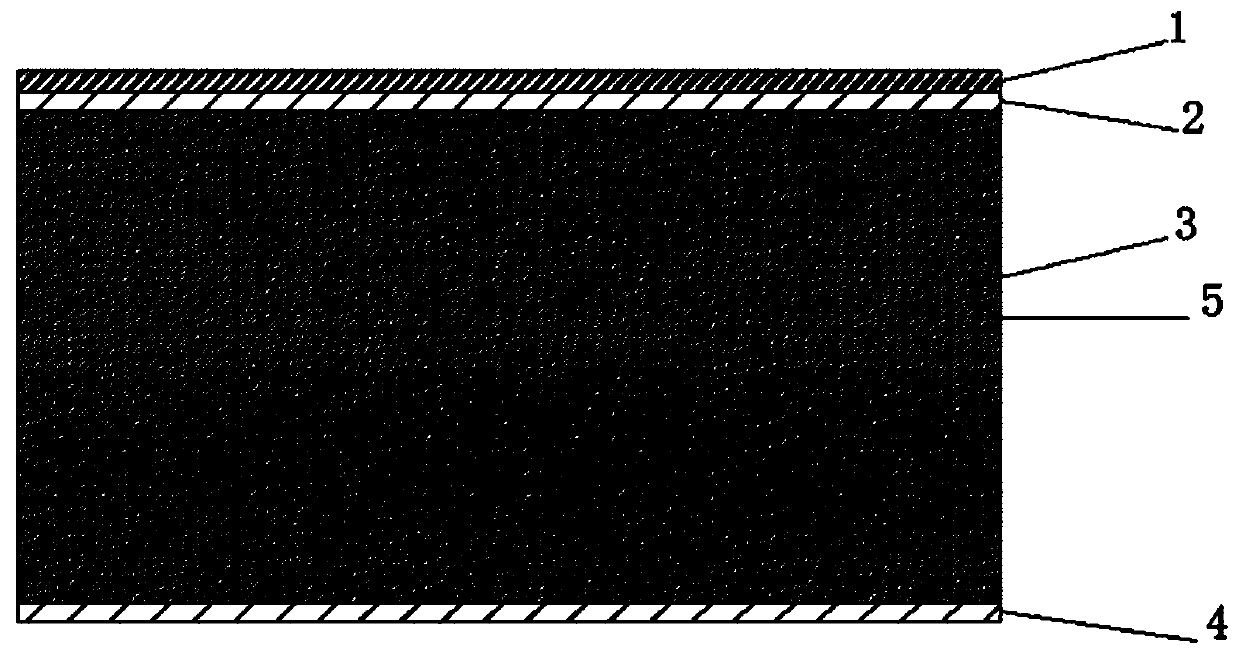

Image

Examples

Embodiment 1

[0050] The raw material is sulfoaluminate cement (CSA82.5) with a component of 700, and the phosphogypsum powder with a component of 300 is acid-washed, dried and ball-milled for 15 minutes. The upper layer of the three-dimensional spacer fabric is composed of polyester and carbon fiber, and the lower layer is composed of It is polyester fiber, the middle yarn is nylon, and the thickness is 10mm. Referring to the standard consistency test method in the "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Method" (GB / T 1346-2011), the water-cement ratio was determined to be 0.33. Prepare a triple test block of 40mm×40mm×160mm, place the formed test piece in a standard curing box with a relative humidity of not less than 90% and a temperature of (20±1)°C, and measure the flexural and compressive strength of the corresponding age value.

[0051] The test results show that the flexural strength reaches 10MPa in 1d and 13MPa in 7d; the compressive stren...

Embodiment 2

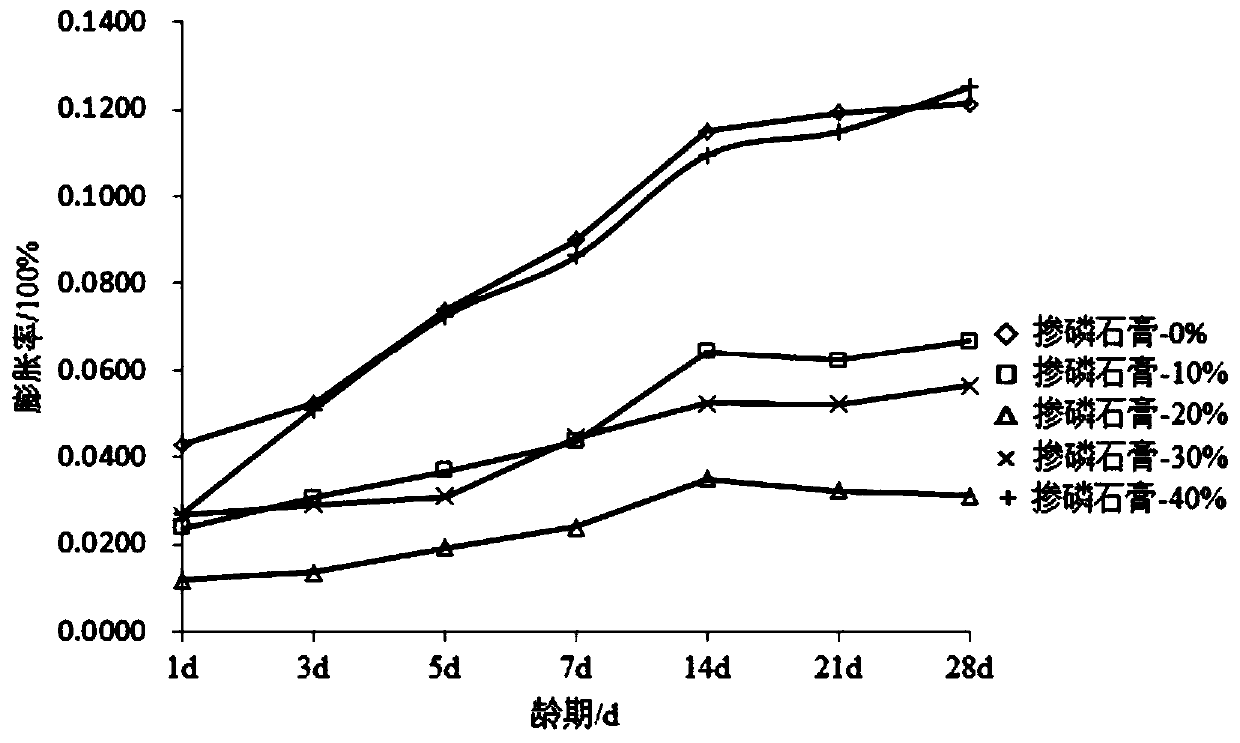

[0071] The raw materials are selected as sulphoaluminate cement (CSA82.5) and pickled phosphogypsum. Referring to the standard consistency test method in the "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Method" (GB / T 1346-2011), the water-cement ratio was determined to be 0.33. Prepare a triple test block of 40mm×40mm×160mm, place the formed test piece in a standard curing box with a relative humidity of not less than 90% and a temperature of (20±1)°C, and measure the volume stability (Table 2), condensation Time (Table 3), expansion rate ( image 3 ), the flexural compressive strength is higher than the corresponding age (Table 4).

[0072] Table 2 volume stability measurement results

[0073]

[0074] Table 3 coagulation time measurement results

[0075] Specimen type Phosphogypsum - 0% Phosphogypsum - 10% Phosphogypsum - 20% Phosphogypsum - 30% Phosphogypsum - 40% Initial setting time / min 158 26 36 42 6...

Embodiment 3

[0087] The method for making pickled phosphogypsum is to pickle once with citric acid aqueous solution, then add quicklime to wash until the upper layer has no suspended oily matter, and finally place the cleaned phosphogypsum in an oven for drying and ball milling for 10-17 minutes to obtain pickled phosphogypsum. plaster.

[0088] The ball milling conditions are as follows: the diameter of the zirconia balls is 3.5×10mm, the filling amount is 60%, the ball milling speed is 16.8r / min, and the ball milling time is changed. Among them, the particle size after ball milling for 5min, 10min, 13min and 15min, the initial and final setting time and 7d expansion rate at 30% phosphorus-doped gypsum are shown in Table 5.

[0089] table 5

[0090] Ball milling time / min 5 10 13 15 Particle size / um 600-900 300-600 400-550 100-300 Initial setting time / min 60 56 40 42 Final setting time / min 62 61 43 45 7d Expansion rate / 100% 0.0195 0.0198 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com