Gel mask and preparation method thereof

A mask and gel technology, applied in the field of gel mask and its preparation, can solve the problems of poor toughness and continuity, poor film-forming property of the mask, poor use process experience, etc., and achieve the effects of excellent toughness and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

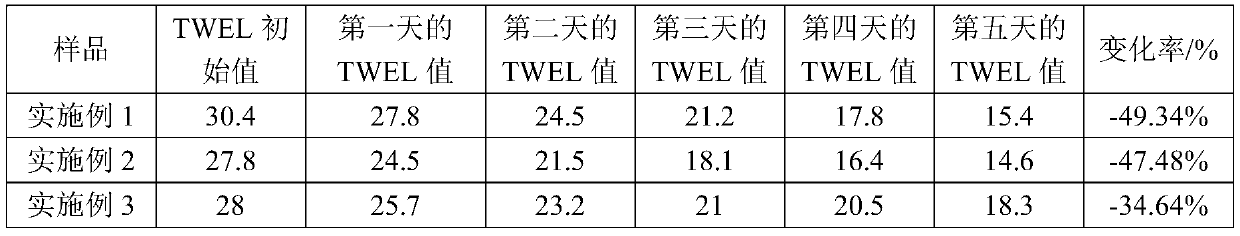

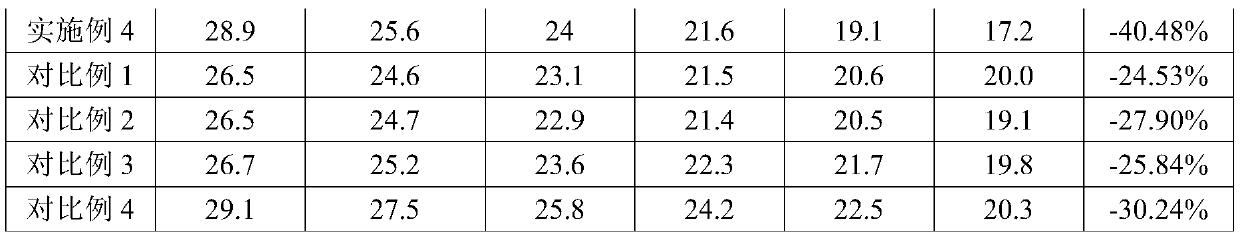

Embodiment 1

[0043](1) Mix 30.93 parts of water, 3 parts of moisturizer (which contains 0.36 parts of glycerin and 2.64 parts of propylene glycol), 33 parts of gel (which contains 0.66 parts of polyvinyl alcohol, 31.35 parts of polyurethane-35, 0.99 parts of acrylic acid (ester) class / C10-30 alkanol acrylate crosspolymer), 0.05 parts of emulsifier (which contains 0.03 parts of PEG-20 methyl glucose sesquistearate, 0.02 part of methyl glucose sesquistearate ) Stir and heat at 70°C until completely dissolved, then homogenize for 2min at a homogenizing speed of 1000r / min to obtain sample A;

[0044] (2) Then sample A was cooled to 45°C, and 1 part of phenoxyethanol and 2 parts of stabilizer (including 1 part of triethanolamine and 1 part of disodium EDTA) were added and stirred evenly to obtain sample B;

[0045] (3) After cooling sample B to 40°C, add 20 parts of skin conditioner (including 4 parts of eggshell membrane extract (purchased from Xi'an Shangcheng Biotechnology Co., Ltd., name SC...

Embodiment 2

[0048] (1) Mix 30.97 parts of water, 5 parts of moisturizer (which contains 1.25 parts of glycerin and 3.75 parts of propylene glycol), 40 parts of gel (which contains 4 parts of polyvinyl alcohol, 34 parts of polyurethane-35, 2 parts of chitosan) , 2 parts of emulsifier (including 1 part of PEG-20 methyl glucose sesquistearate and 1 part of methyl glucose sesquistearate) stirred and heated at 70°C until completely dissolved, then homogenized for 2 minutes , the homogenization speed was 1000r / min, and sample A was obtained;

[0049] (2) Then sample A was cooled to 45°C, and 1 part of phenoxyethanol and 1 part of stabilizer (including 0.2 part of triethanolamine and 0.8 part of EDTA disodium) were added and stirred evenly to obtain sample B;

[0050] (3) After cooling sample B to 40°C, add 20 parts of skin conditioner (including 12 parts of eggshell membrane extract, 5 parts of hydrolyzed yeast protein and 3 parts of Lactobacillus / soybean milk fermentation product filtrate) and...

Embodiment 3

[0053] (1) Mix 27.82 parts of water, 10 parts of humectant (including 5 parts of butanediol and 5 parts of xylitol), 50 parts of gel (including 1.5 parts of polyvinyl alcohol, 47.5 parts of polyurethane-35, 1 part of acrylic acid (esters / C10-30 alkanol acrylate crosslinked polymer), 2 parts of emulsifier (including 1 part of PEG-20 methylglucose sesquistearate, 1 part of polyglycerol-10) stirring and heating 90°C until it is completely dissolved, then homogenize for 6 minutes at a speed of 3000r / min to obtain sample A;

[0054] (2) Then sample A was cooled to 45°C, and 0.1 part of methylparaben and 0.05 part of stabilizer (including 0.03 part of sodium hydroxide and 0.02 part of disodium EDTA) were added and stirred evenly to obtain sample B;

[0055] (3) After cooling sample B to 40°C, add 10 parts of skin conditioner (including 4 parts of eggshell membrane extract, 1 part of Lactobacillus / soymilk fermentation product filtrate and 5 parts of yuzu fruit extract) and stir evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com