Method for optimizing horizontal arrangement distance of hazardous chemical substance gas detector

A technology of gas detectors and optimization methods, which is applied in the directions of instruments, predictions, and special data processing applications, etc., can solve the problems of untargeted technical standards for the layout of gas detectors for hazardous chemicals, etc., and achieve accurate and reliable simulation calculation results of FLACS software Belief, the effect of increasing credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

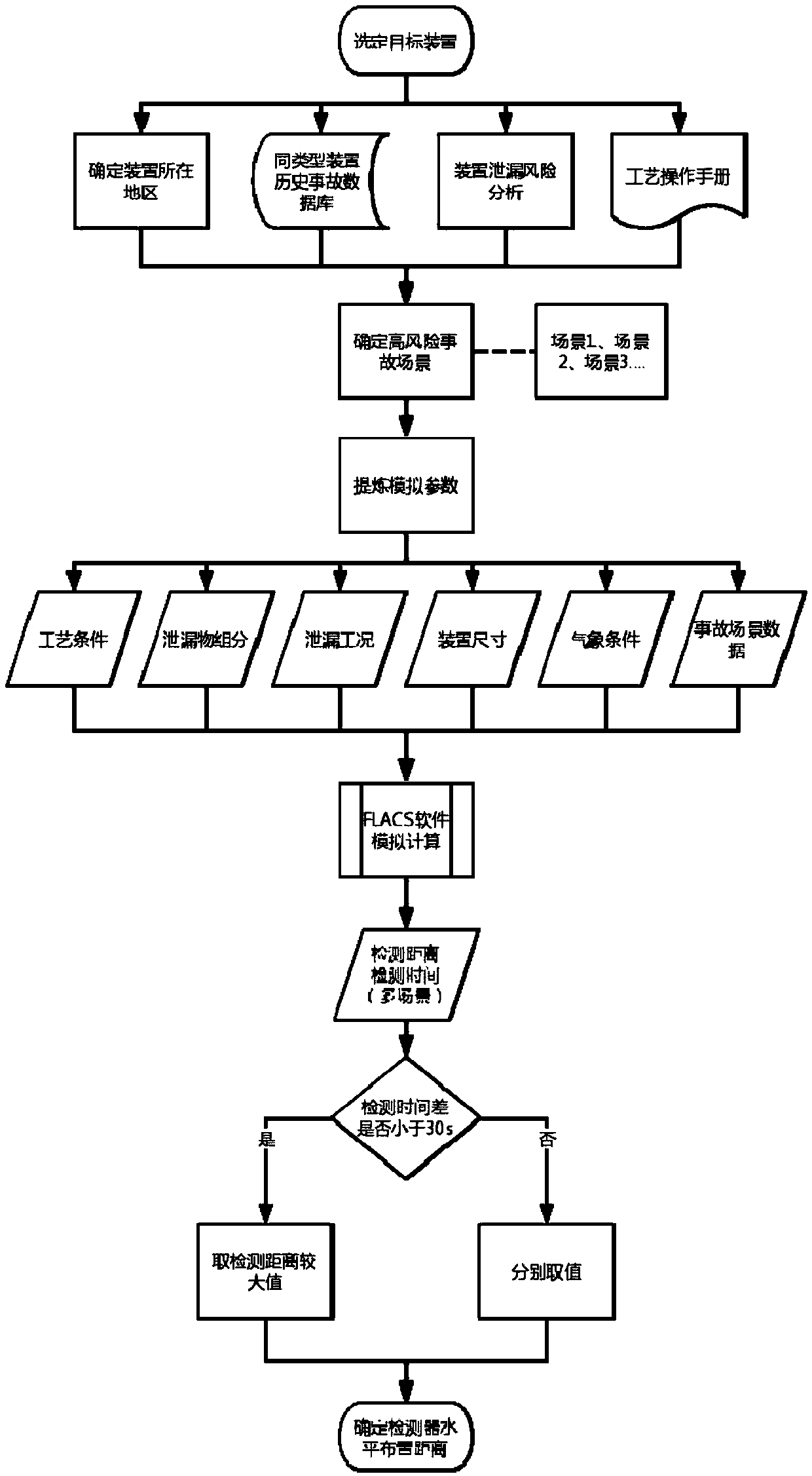

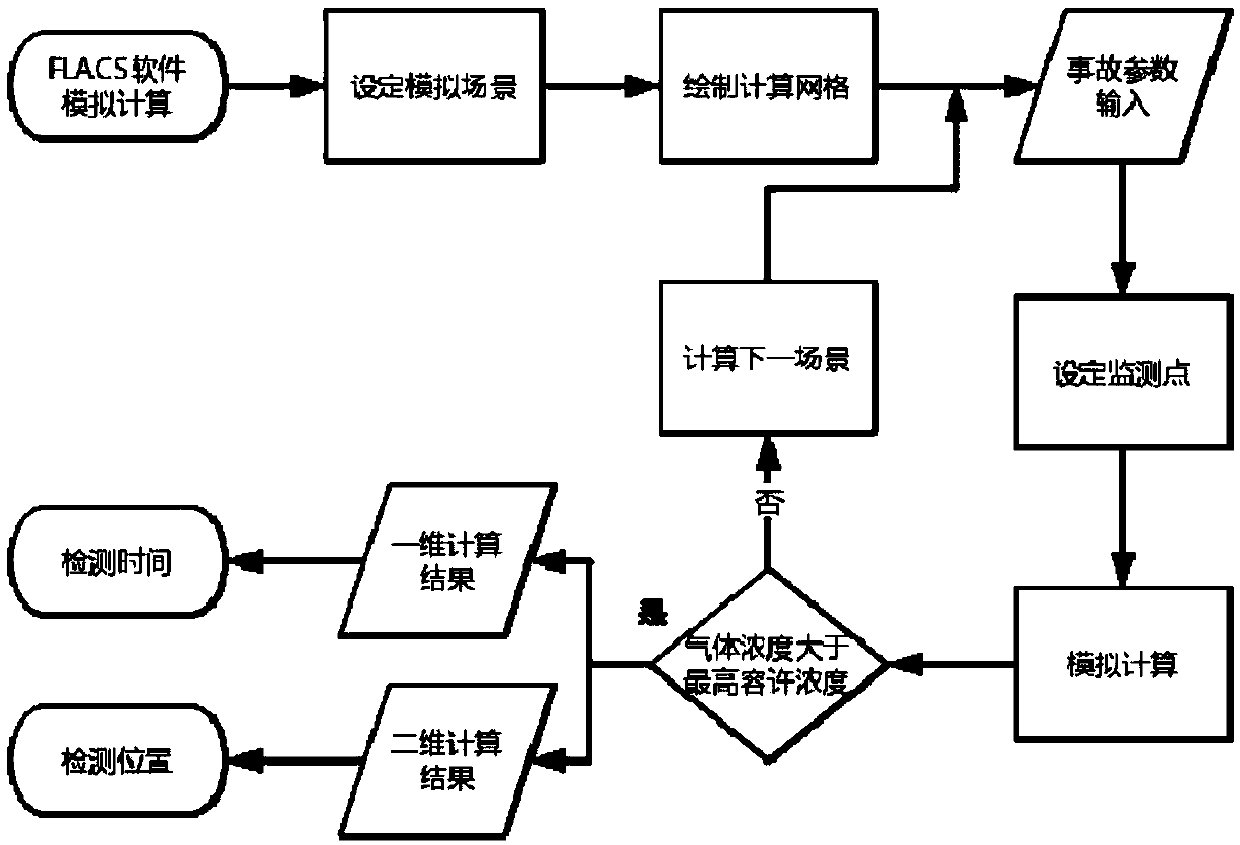

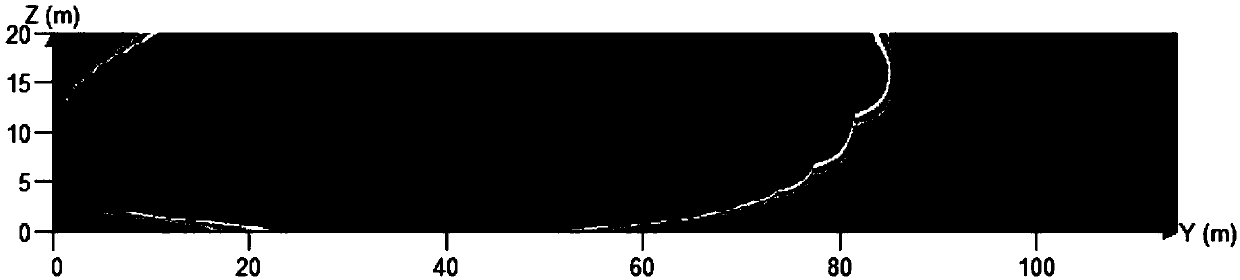

[0055] The basic idea of the present invention is: for the target chemical plant, comprehensively consider multiple factors including: meteorological conditions, surrounding environment, device leakage risk, historical accident cases, medium types, process parameters, etc., use FLACS software to simulate various leakage scenarios, analyze The horizontal layout distance of detectors that can cope with various leakage scenarios is obtained.

[0056] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0057] Such as figure 1 As shown, the present invention is based on the analysis of the target device and the investigation of historical accidents, and uses the means of simulation calculation to optimize the horizontal layout distance of gas detectors. The specific scheme is as follows: An optimization of the horizontal layout distance of gas detectors for hazardous chemicals method, after selecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com