SEM-EDS combined test method for metal foreign matters in lithium battery material

A technology of SEM-EDS and metal foreign matter, which is applied in the field of SEM-EDS combined testing of metal foreign matter in lithium battery materials, can solve problems such as poor accuracy of test results, achieve long service life, ensure consistency, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

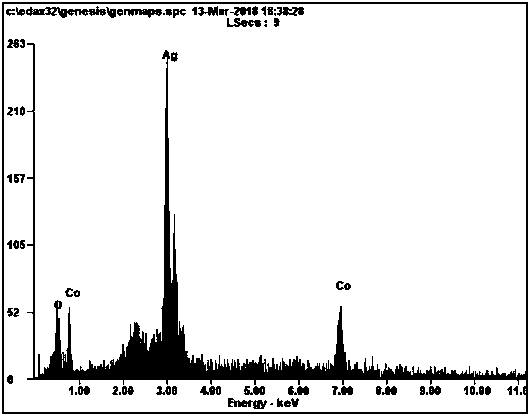

Embodiment 1

[0037] A. Weigh 200g of cobalt hydroxide, the precursor of lithium battery cathode material, and place it in a 500mL plastic test bottle, put it into a qualified clean magnet (with a magnetic field strength of 5500GS), fill it with high-purity water, shake it up and down for 10 times, and put the test bottle in In the mixer, mix clockwise and counterclockwise for 15 minutes at the mixer speed of 120r / min, then take it off;

[0038] B. After the mixing is completed, take off the test bottle, pour out the sample slurry in the test bottle, take out the magnet, rinse the adhered material 4 times with high-purity water, then put the magnet into a 400mL beaker and add water until the magnet is completely covered. Place the beaker in an ultrasonic instrument for ultrasonic cleaning for 30 seconds, then remove the magnet, wash it with high-purity water three times, then wash it once with absolute ethanol, and dry it naturally;

[0039] C. Cut the conductive tape according to the size ...

Embodiment 2

[0045] A. Weigh 200g of cobalt tetroxide, the precursor of lithium battery cathode material, and place it in a 500mL plastic test bottle, put it into a qualified clean magnet (magnetic field strength of 6000GS), fill it with high-purity water, shake it up and down for 10 times, and place the test bottle in a mixing chamber. In the homogenizer, mix clockwise and counterclockwise for 15 minutes at the speed of the mixer at 120r / min, then take it off;

[0046] B. After the mixing is completed, take off the test bottle, pour out the sample slurry in the test bottle, take out the magnet, rinse the adhered material with high-purity water for 5 times, then put the magnet into a 400mL beaker and add water until the magnet is completely covered. Place the beaker in an ultrasonic instrument for ultrasonic cleaning for 30 seconds, then remove the magnet, wash it with high-purity water three times, then wash it once with absolute ethanol, and dry it naturally;

[0047] C. Cut the conducti...

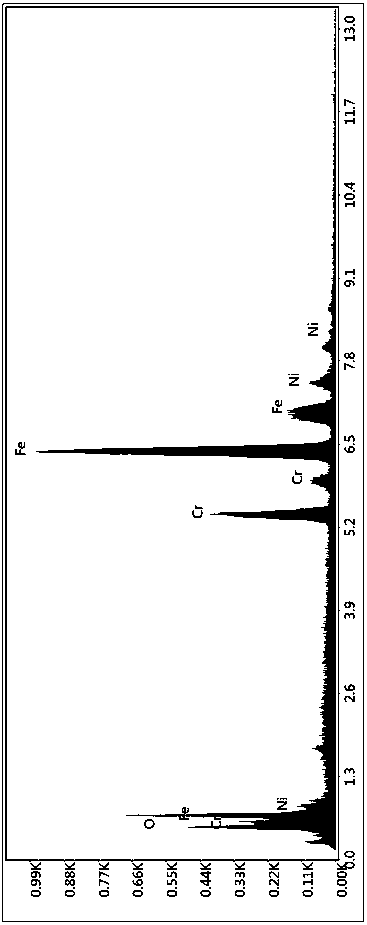

Embodiment 3

[0053] A. Weigh 200g of cobalt tetroxide, the precursor of lithium battery cathode material, and place it in a 500mL plastic test bottle, put it into a qualified clean magnet (with a magnetic field strength of 5000GS), fill it with high-purity water, shake it up and down for 10 times, and place the test bottle in a mixing chamber. In the homogenizer, mix clockwise and counterclockwise for 15 minutes at the speed of the mixer at 120r / min, then take it off;

[0054] B. After the mixing is completed, take off the test bottle, pour out the sample slurry in the test bottle, take out the magnet, rinse the adhered material with high-purity water for 3 times, then put the magnet into a 400mL beaker and add water until the magnet is completely covered. Place the beaker in an ultrasonic instrument for ultrasonic cleaning for 30 seconds, then remove the magnet, wash it with high-purity water three times, then wash it once with absolute ethanol, and dry it naturally;

[0055] C. Cut the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com