Combined core mould structure for forming grain of rocket engine and use method thereof

A technology of rocket motor and grain, which is applied in rocket motor devices, machines/engines, mechanical equipment, etc., can solve the problems of inability to meet disassembly requirements, difficulty in mold assembly and demoulding, and achieve stable structure, good physical performance, and economical operation. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be further described in conjunction with the embodiments, but the scope of protection claimed by the present invention is not limited to the scope of the embodiments.

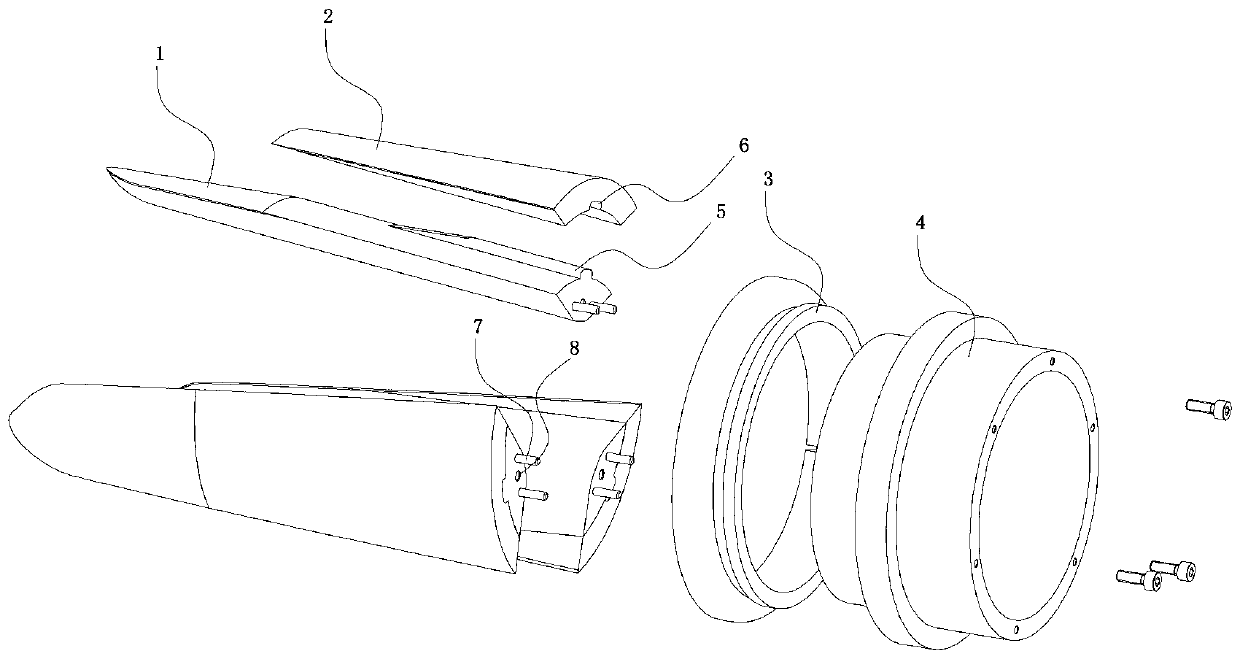

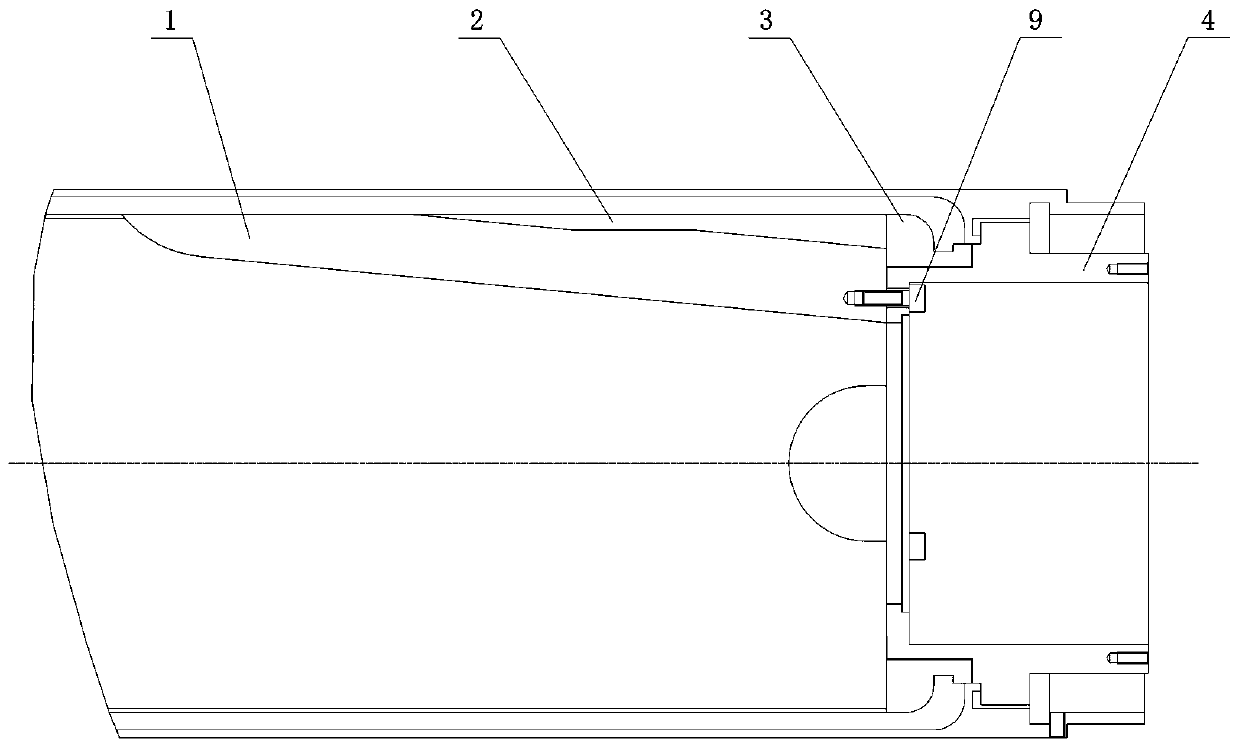

[0026] Such as Figure 1-4 As shown, a composite core mold structure used for rocket engine grain molding, a plurality of special-shaped notches are provided on the side of the grain, the structure includes multiple sets of special-shaped components, and the multiple sets of special-shaped components cooperate with the special-shaped notches of the grain to form a cylinder Each group of special-shaped block components is provided with a first special-shaped block 1 and a second special-shaped block 2 along the circumferential direction. The first special-shaped block contacts the grain to be formed and is a metal piece; the second special-shaped block is located on the side of the first special-shaped block away from the grain , And the second special-shaped block is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com