Deep foundation pit tower crane waterproof structure of weakly permeable soil and construction method

A waterproof structure and permeability technology, applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of insufficient attention to tower body protection, damage to the tower body, and impact on the safety of tower cranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

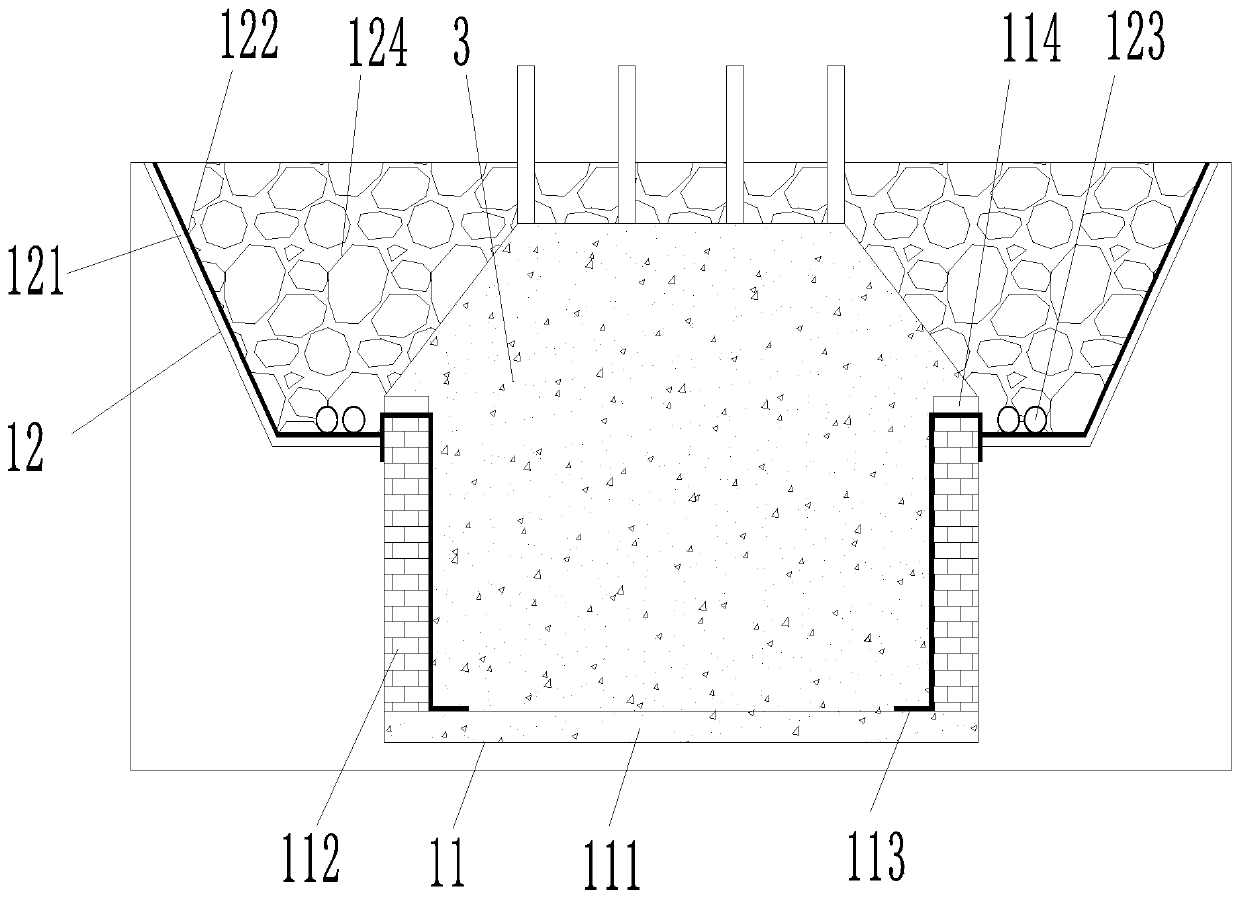

[0028] Such as figure 1 and Figure 4 As shown, a tower crane waterproof structure of a deep foundation pit with weak permeability soil includes a foundation pit 1 and a water collection well 2. The foundation pit 1 includes a foundation pit 11 and a drainage groove 12. Inside, the bottom surface of the foundation pit 11 is provided with a 120mm concrete cushion 111, and the inner wall of the foundation pit 11 is provided with a brick membrane 112. The top surface of the brick membrane 112 is 80mm higher than the bottom of the drainage groove 12, and A waterproof layer 113 made of a waterproof coil is laid on the tire membrane 112, and the top side of the waterproof layer 113 extends outward to the outer wall of the brick tire membrane 112. Effective waterproofing on the inside. The waterproof layer 113 on the top surface of the brick tire membrane 112 is seamlessly connected with the concrete pressure plate 114, and the area between the concrete cushion 111 and the waterpro...

Embodiment 2

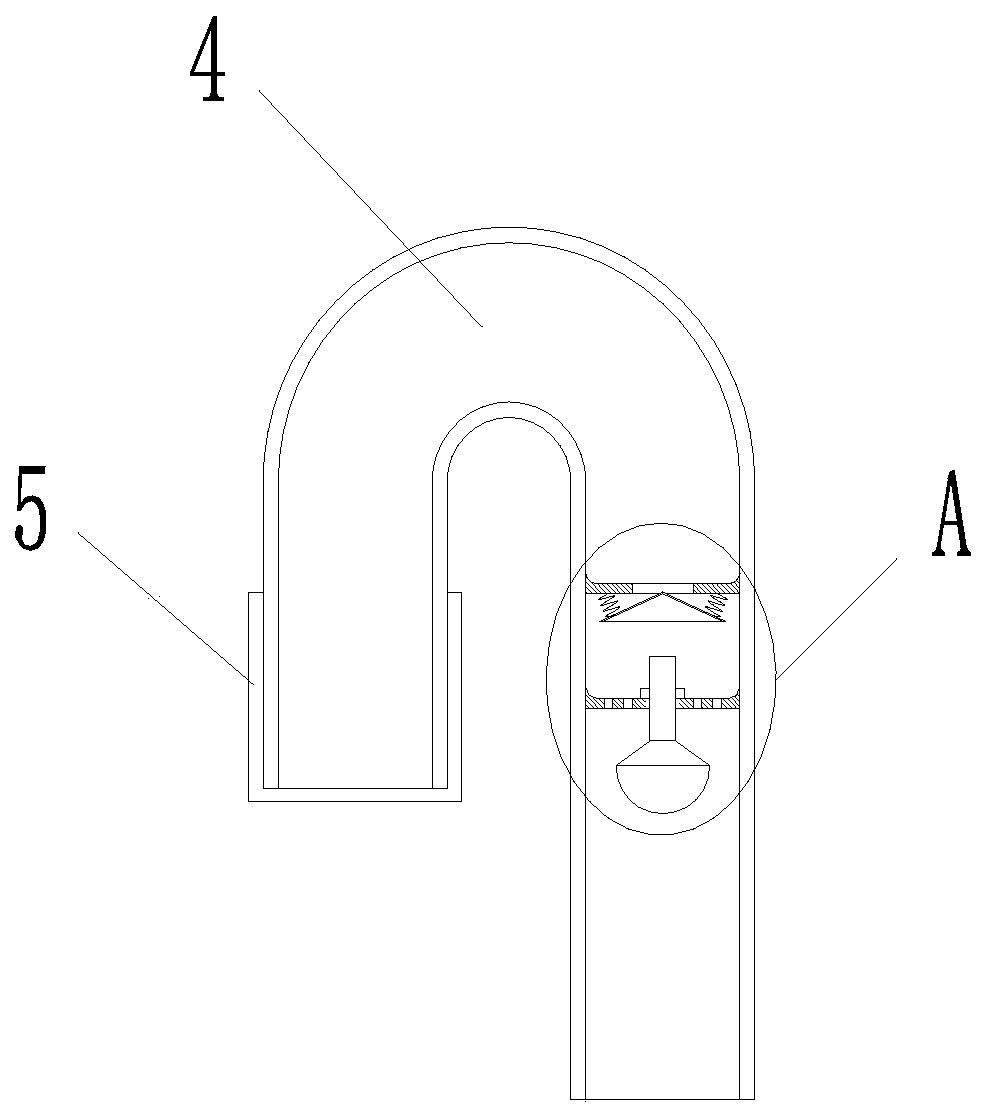

[0032] Such as figure 2 and image 3 As shown, the drainage pipe 123 is fixedly connected and communicated with a pipe 4, the branch pipe 4 is a U-shaped structure, and the free end of the branch pipe 4 is provided with a filter 5 for filtering sand and gravel to prevent clogging and causing water accumulation in the drainage ditch 12 , while preventing the foul smell in the water collection well 2 from polluting the drainage ditch 12 and the surrounding environment.

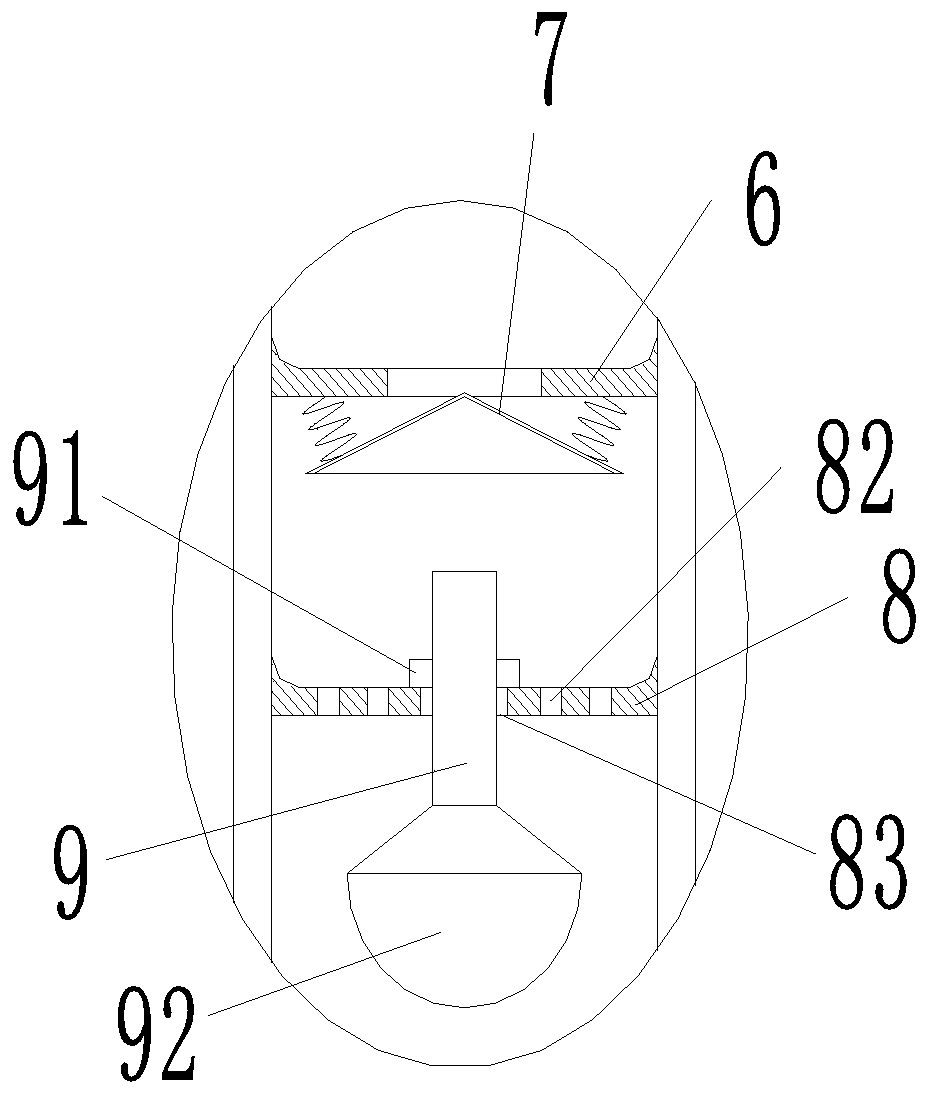

[0033] Further, the branch pipe 4 is provided with an anti-backflow structure for protecting the water in the sump 2 from flowing back into the drainage groove 12. The anti-backflow structure includes a fixed disc 6, a flow blocking member 7, a limiting member 8 and a buoyancy member 9 , the fixed disk 6 is fixedly connected to the inner wall of the branch pipe 4, the flow blocking piece 7 is connected to the lower surface of the fixed disk 6 through a spring, the flow blocking piece 7 has a conical structure,...

Embodiment 3

[0035] Such as Figure 1 to Figure 4 As shown, the present invention also discloses a construction method for a tower crane waterproof structure of a deep foundation pit with weakly permeable soil, comprising the following steps:

[0036] Step 1. Clean up the ground garbage and excavate the foundation pit 11 and drainage trench 12 according to the construction requirements, pour a 120mm concrete cushion 111 on the bottom of the foundation pit 11, and build brick tires on the inner wall of the foundation pit 11 film 112;

[0037] Step 2: A waterproof layer 113 is provided on the inner wall of the brick tire membrane 112, and the waterproof layer 113 is folded to the outer wall of the brick tire membrane 112, and is seamless on the waterproof layer 113 on the top surface of the brick tire membrane 112 Connect a concrete pressure plate 114;

[0038] Step 3: Pour concrete in the area between the concrete cushion 111 and the first waterproof layer 113 to form a tower crane abutment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Lap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com