Dyeing method of elastic patterned gray blended knitted fabric

A technology of knitted fabrics and dyeing methods, applied in the field of dyeing and finishing technology, can solve the problems of high energy consumption, long process time, cumbersome procedures, etc., and achieve the effects of avoiding color difference, simplifying the dyeing process, and optimizing the dyeing and finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

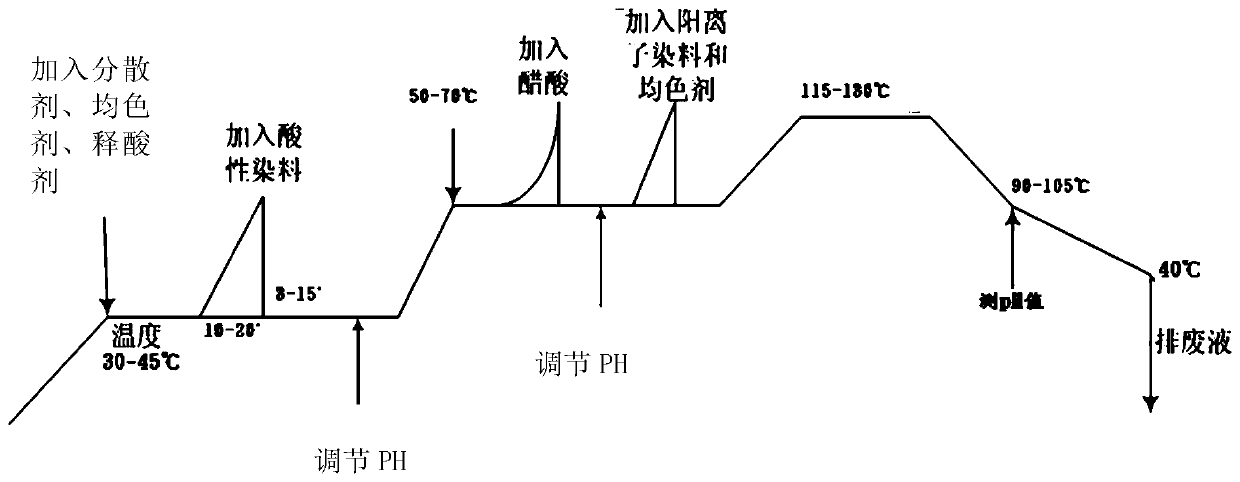

[0030] A method for dyeing elastic flower gray blended knitted fabrics, the method comprising the following steps:

[0031] 1) Pre-treatment, degreasing the elastic greige of the elastic flower gray blended knitted fabric blended with 53% polybutylene terephthalate cationic modified fiber, 42% polyamide fiber and 5% polyurethane fiber , fixed embryo;

[0032] 2) Dyeing, put the pre-treated elastic gray cloth into the dyeing vat, add water, then add 0.3g / L dispersant according to the amount of water added, 2 / 3 of the total amount of color leveling agent, 0.3g / L of acid release agent.

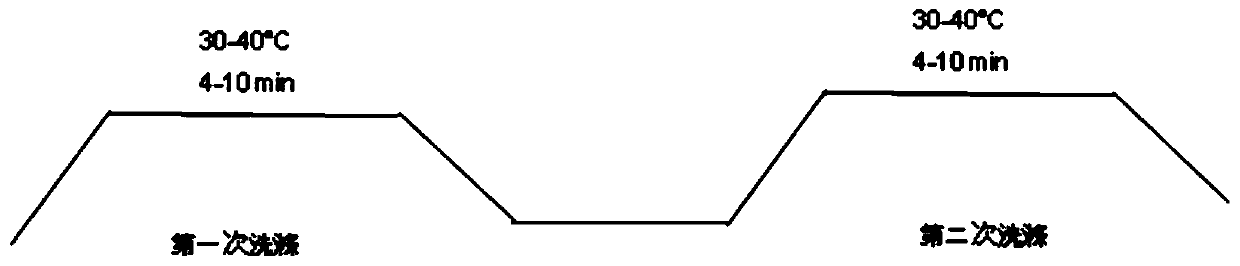

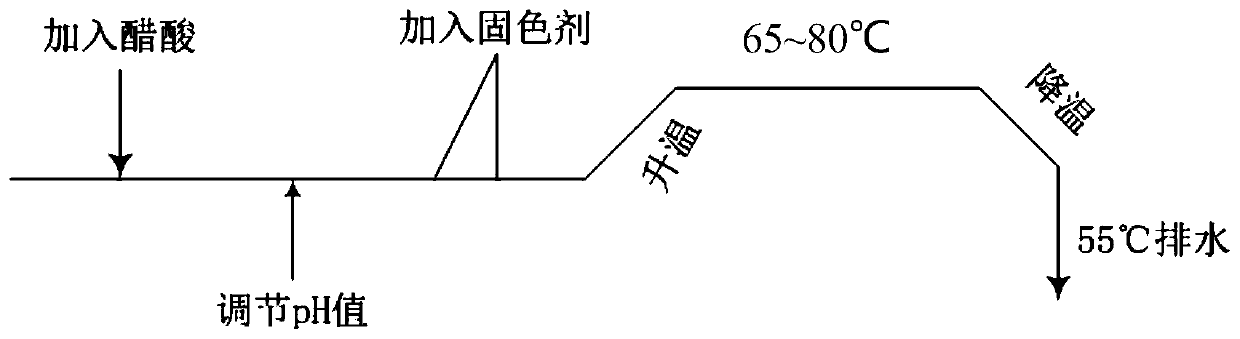

[0033] Heat to raise the temperature of the dye solution to 40°C, add acid dye within 15 minutes, run for 6 minutes, control the pH value to 6-7, linearly raise the temperature to 60°C at a heating rate of 1°C / min, add acetic acid to adjust the pH value to 3.5 After adding an appropriate amount of cationic dye and the balance of the color leveling agent, the temperature was raised linearly to 1...

Embodiment 2

[0040] A method for dyeing elastic flower gray blended knitted fabrics, the method comprising the following steps:

[0041] 1) Pre-treatment, degreasing the elastic greige of the elastic flower gray blended knitted fabric blended with 53% polybutylene terephthalate cationic modified fiber, 42% polyamide fiber and 5% polyurethane fiber , fixed embryo;

[0042]2) Dyeing, put the pre-treated elastic gray cloth into the dye vat, add water, then add 1.0g / L dispersant according to the amount of water added, 2 / 3 of the total amount of color leveling agent, 0.4g / L of acid release Adding agent, heating to raise the temperature of the dye solution to 40°C, adding acid dye in 15 minutes, running for 6 minutes, controlling the pH value to 6-7, linearly raising the temperature to 60°C at a heating rate of 1.2°C / min, adding acetic acid to adjust the pH value to 3.2. After adding an appropriate amount of cationic dyes and the balance of the color leveling agent, linearly raise the temperatu...

Embodiment 3

[0048] A method for dyeing elastic flower gray blended knitted fabrics, the method comprising the following steps:

[0049] 1) Pre-treatment, degreasing the elastic greige of the elastic flower gray blended knitted fabric blended with 53% polybutylene terephthalate cationic modified fiber, 42% polyamide fiber and 5% polyurethane fiber , fixed embryo;

[0050] 2) Dyeing, put the pre-treated elastic gray cloth into the dye vat, add water, then add 1.2g / L dispersant according to the amount of water added, 0.2g / L acid release agent for color leveling agent of 2 / 3 of the total amount added, Heat to raise the temperature of the dye solution to 40°C, add acid dye in 15 minutes, run for 6 minutes, control the pH value to 6-7, linearly raise the temperature to 60°C at a heating rate of 3°C / min, add acetic acid to adjust the pH value to 3.5, add Proper amount of cationic dyes and the remaining amount of color leveling agent are linearly raised to 120°C at a heating rate of 3°C / min, run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com