Exterior wall coating and preparation method thereof

A technology for exterior wall coatings and pigments, applied in the field of coatings, can solve problems such as poor heat insulation effect and failure to meet user requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of exterior wall paint, calculated in parts by mass, the exterior wall paint comprises 30 parts of pure acrylic emulsion, 65 parts of colored stone sand powder, 20 parts of microcrystalline foamed ceramic powder, 6 parts of black tourmaline powder, 3 parts of hydroxyethyl cellulose, 12 parts of shell powder, 10 parts of medical stone powder, 0.5 parts of citric acid ester, 1.2 parts of lauryl alcohol ester, 0.12 parts of antifoaming agent, 4 parts of silicon carbide whiskers and 30 parts of water.

Embodiment 2

[0037] A kind of exterior wall paint, calculated in parts by mass, the exterior wall paint comprises 35 parts of pure acrylic emulsion, 100 parts of quartz powder, 30 parts of microcrystalline foamed ceramic powder, 8 parts of black tourmaline powder, 1 part of hydroxyl Ethyl cellulose, 14 parts of shell powder, 15 parts of medical stone powder, 1 part of citric acid ester, 1.2 parts of dodecyl alcohol ester, 0.12 part of antifoaming agent, 6 parts of silicon carbide whiskers and 35 parts Parts of water.

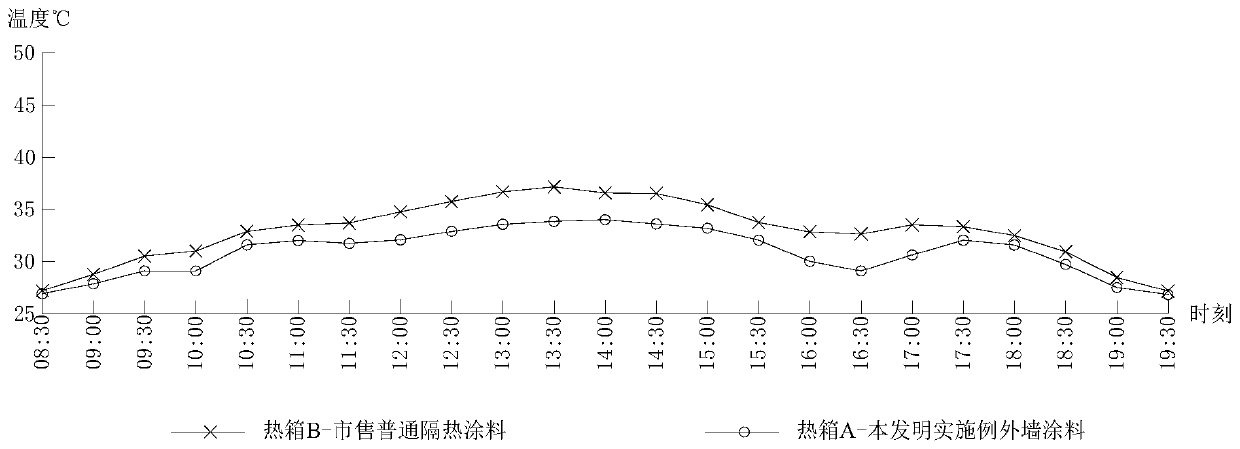

[0038] The exterior wall coatings prepared in Examples 1 to 2 of the present invention are not only environmentally friendly, non-toxic, low energy consumption, and odorless, but also, according to the GB / T 9755-2014 standard, the scrub resistance and alkali resistance of the exterior wall coatings prepared in the examples of the present invention Water resistance, temperature change resistance, stain resistance, artificial weather aging resistance and water permeability far...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com