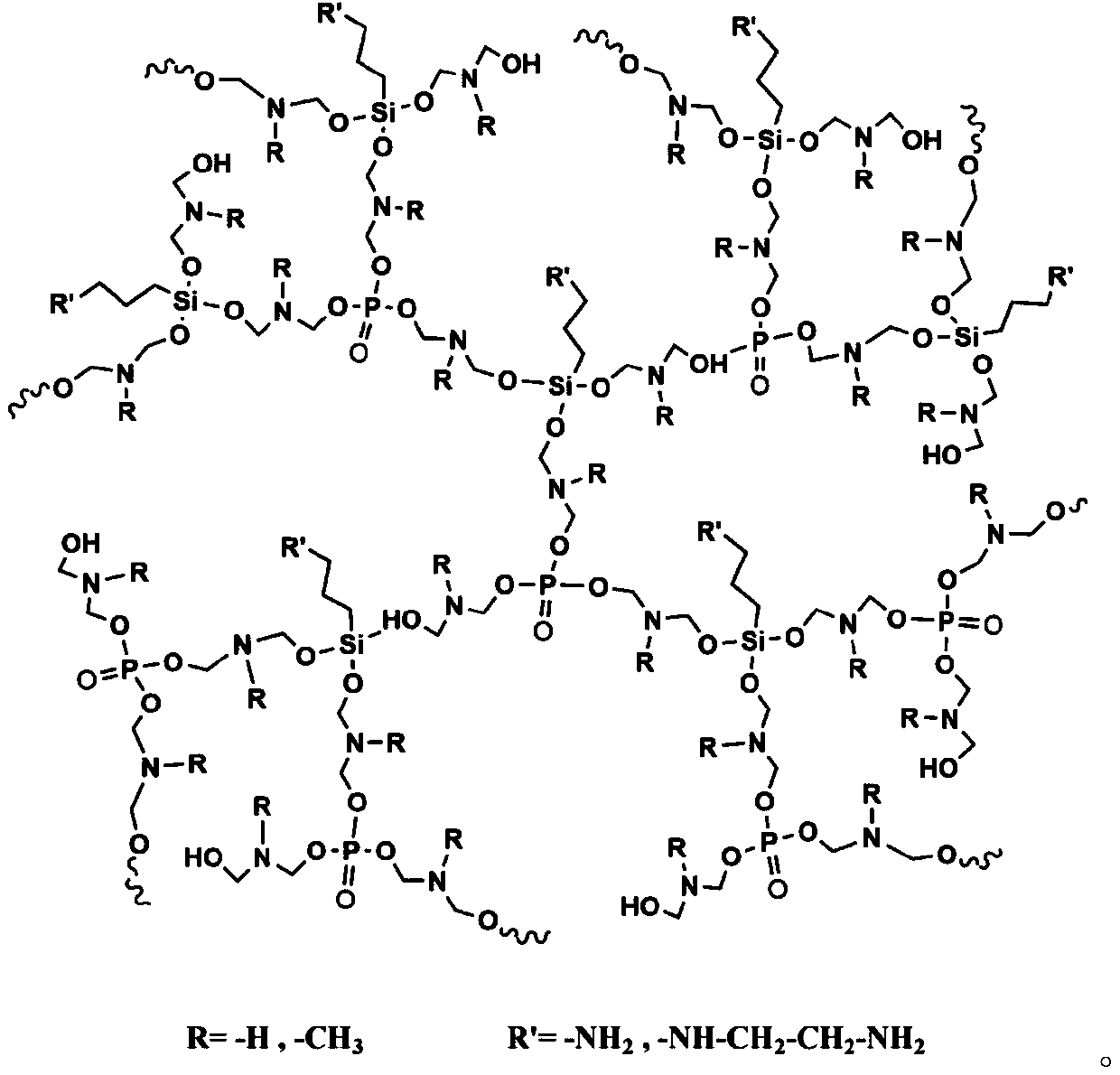

Phosphorus-silicon-nitrogen ternary synergistic flame retardant and preparation method thereof

A technology of synergistic flame retardant and trialkoxy phosphate, which is applied in the field of phosphorus-silicon-nitrogen ternary synergistic flame retardants and its preparation, can solve the problems of volatile toxic solvents and catalysts, and achieve low cost and wide application prospects , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add (3-aminopropyl)trimethoxysilane, trimethyl phosphate and diethanolamine into a three-necked flask at a molar ratio of 1:1:3, stir under the protection of nitrogen, and control the reaction temperature at 80-200 Between ℃, react for 4 to 12 hours until no distillate is produced. Add the obtained product into a 2000 molecular weight dialysis bag, dialyze for 24 hours, and then perform rotary evaporation to obtain the final product phosphorus-silicon-nitrogen ternary synergistic flame retardant.

Embodiment 2

[0025] Add (3-aminopropyl)trimethoxysilane, triethyl phosphate and N-methyldiethanolamine into a three-necked flask at a molar ratio of 1:1:3, stir under the protection of nitrogen, and control the reaction temperature Between 80 and 200°C, react for 4 to 12 hours until no distillate is produced. Add the obtained product into a 2000 molecular weight dialysis bag, dialyze for 24 hours, and then perform rotary evaporation to obtain the final product phosphorus-silicon-nitrogen ternary synergistic flame retardant.

Embodiment 3

[0027] Add (3-aminopropyl)triethoxysilane, triethyl phosphate and diethanolamine into a three-necked flask at a molar ratio of 1:1:3, stir under the protection of nitrogen, and control the reaction temperature at 80- Between 200°C, react for 4 to 12 hours until no distillate is produced. Add the obtained product into a 2000 molecular weight dialysis bag, dialyze for 24 hours, and then perform rotary evaporation to obtain the final product phosphorus-silicon-nitrogen ternary synergistic flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com