Enhanced repair method after damage of composite material blade skin

A technology of composite materials and blades, which is applied in the repair field of rotor system composite blades, can solve the problems of skin step difference, local stress concentration, easy secondary debonding, and heavy weight gain of blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

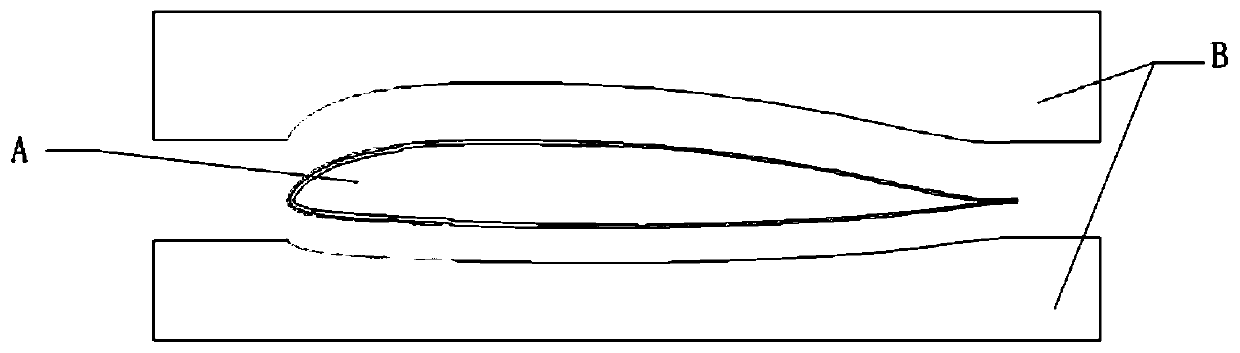

[0050] In conjunction with the accompanying drawings, the implementation process of the present invention is described more comprehensively, specifically including the following steps:

[0051] Step 1: Weigh the repaired blade A before repair, and record the weight before repair.

[0052] Step 2: Excavate and clean the damaged area 8 of the skin and filling core material in the repaired blade A, take the damaged area as the cleaning center, peel off the skin in this area, and clean up the area outside this area layer by layer in a stepwise manner. Each layer of skin 11 gradually increases the cleaning range from the inner skin to the outer skin, and the step width can be 15mm to 25mm. The cleaning area is generally round or rectangular, as neat as possible.

[0053] Step 3: Carry out overall grinding and cleaning of the damaged area 8 of the skin and filling core material and the area of the original skin 11 peeled off by steps; place a layer of glued filling core material ...

Embodiment 2

[0064] When both the upper and lower airfoils of a composite blade to be repaired are damaged, debonded, or have penetrating scars, perform the repairs as follows:

[0065] Step 1: Carry out paint stripping treatment on the damaged area of the blade skin, and weigh it before repairing.

[0066] Step 2: Clean up the damaged area of the blade skin, take the damaged area as the cleaning center, peel off the upper and lower airfoil skins in this area, and clean the layers of skin outside this area layer by layer in a stepwise manner, Gradually increase the cleaning range from the inner skin to the outer skin.

[0067] Step 3: Lay a layer of film material on the cleared and filled core material area as a whole.

[0068] Step 4: Give priority to the side with the larger damage area; if the area is the same, give priority to the lower wing. Return the blade to the forming die with the side to be repaired facing up.

[0069] Step 5: Refill the core material in the cleaned area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com